Heat Cured Rubber(HCR) Molding | Definition & Process

What is HCR?

Heat Cured Rubber, or High Consistency Rubber (HCR) is a silicone elastomer formed of straight chains with very high molecular weight. This system is cured with an organic peroxide crosslinker or a platinum catalyst. The silicone backbone is composed of repeating Si-O chains which are extremely flexible in nature giving this chemical structure unique properties such as a broad operating temperature range, weatherability, being hydrophobic, bio-inertness, electrical insulation, and an overall long life span.

High Consistency Rubber (HCR) is also referred to as Heat Cured Rubber or HTV (High Temperature Vulcanizing) silicone rubber. This material is made from reactive silicone with very high-weight macromolecules.

Heat Cured Rubber elastomers have outstanding properties and are far superior to conventional organic elastomers. They exhibit exceptional mechanical strength at temperature and can be used at temperatures ranging from -50 °C to +300 °C. The aging resistance of these elastomers highlights their fundamental qualities such as the fact that they are chemically inert, their photo-oxidative stability and the absence of residual reactive groups once cured. A wealth of colorings are possible.

By using a sufficiently fine silica filler it is even possible to make transparent articles for use in food and paramedical applications. The addition of various additives opens unlimited customization of HCRs to create solutions to all kinds of existing and new applications in Aerospace, Automotive, Healthcare, Oil and gas, Construction, and Electronics. Most recent examples are heat transfer additives for Electrical Vehicles, electrically conductive materials for Power or Consumer Electronics, and antibacterial solutions for Healthcare applications.

High Consistency Rubber (HCR) is the material of choice in manufacturing rubber parts through the transfer molding process or compression molding. HCRs have outstanding properties and are far superior to conventional organic elastomers including good thermal stability, excellent mechanical strength, and fire resistance with low smoke emissions and non-corrosive and non-toxic combustion gasses.

What is HCR Injection Molding?

Transfer molding process is a closed mold system that incorporates a container above the mold where the rubber sits and gets pushed into the mold using a piston-powered gate system. This process transfers the silicone material into the mold and heats it under pressure to produce the cured part. The silicone transfer molding process is ideal for manufacturing high-precision silicone molded parts as well as over-molding with other materials and allowing for molding complex geometries.

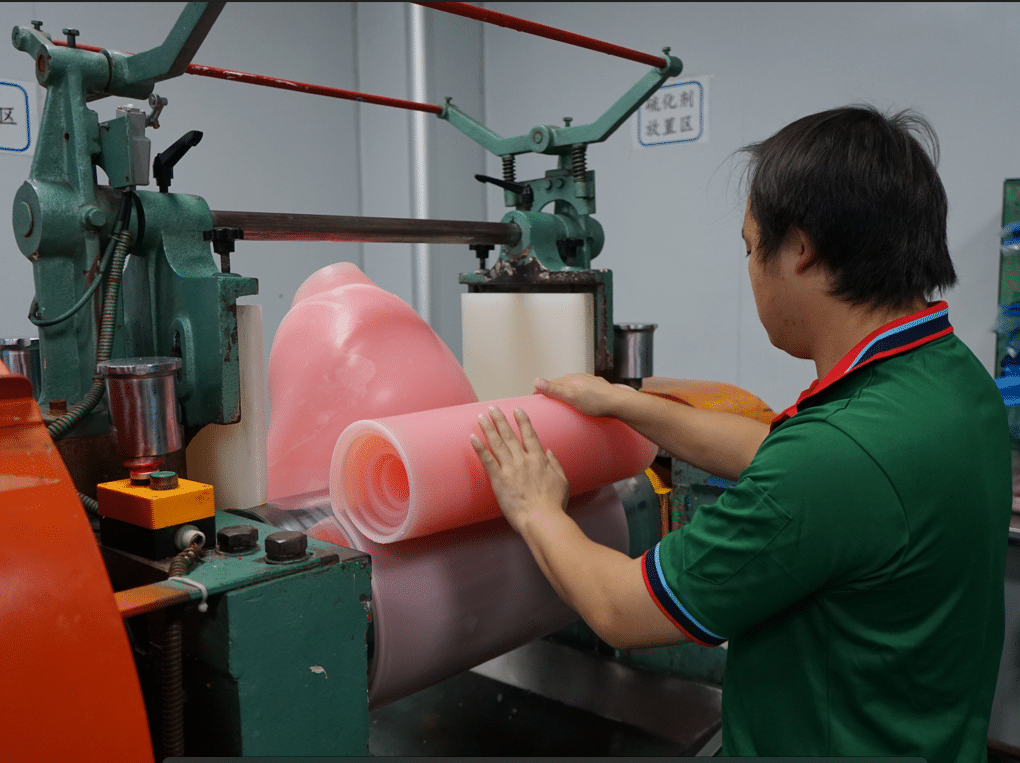

The combination of HCR silicone rubber and the transfer molding process leads to high quality manufactured parts that offer design flexibility and shorter production cycles than other types of molding. HCRs are pre-mixed compounds, masterbatches, or partially vulcanized sheet materials with a higher viscosity index, a different curing system, and longer cure times than LSRs. Although HCRs can be injection molded, compression molding and transfer molding are often used for products other than silicone tubes and cords.

Yet HCR molding offers lower design, machining, and equipment costs than the LSR process. HCR injection molding and LSR injection molding have some similarities, but the process for high consistency rubber requires several more steps. During production, HCR silicones are fed into a heated barrel and injected into a mold where vulcanization occurs. HCR cure time is determined by parameters such as part cross-section thickness, heat transfer, and mold temperature.

Transfer molding is similar to compression molding in several ways: it uses HCRs, pressed from an auxiliary chamber (known as a transfer pot) into a closed pressurized mold system that incorporates a heated container above the mold where the silicone rubber is charged using a piston-powered gate and runner system that can move relatively hard materials into the mold before heating.

The silicone rubber transfer molding process is ideal for manufacturing high precision silicone molded parts as well as ‘over-molding’ with other materials, thus enabling the molding of complex geometries. The combination of HCR and the transfer molding process leads to high quality manufactured parts that offer design flexibility and shorter production cycles.

Transfer molding differs from compression in that the mold is fully enclosed and not in two parts. For this reason, it also differs from injection molding in that requires higher pressure to fill the mold. This also allows transfer molding to accept added fibers or matrices on its outer layers, to produce customized reinforced parts.

Further Reading:

The main advantages of transfer molding processing include:

Uniform, accurate and more consistent parts compared to compression molding due to the one-piece mold and high dimensional tolerance

Efficient and agile capacity for accepting different reinforcement fibers pre-positioned in the mold, including glass, carbon and aramid, as well as natural plant fibers.

Compression molding uses high pressure to squeeze a pre-formed piece of rubber into a mold between two or more plates, depending on the part or product configuration. This process is generally done by hand in the open mold where the mold is closed, the silicone rubber cures, then the part is de-molded. This method of molding silicone rubber is used for manufacturing simple rubber parts that can be easy to manufacture prototypes in a wide range of part sizes.

For this process, the silicone rubber remains flexible and then placed in a heated mold and closed using a sealed clasping system, with pressure applied to force the material to fill the entire cavity. The heat and pressure are maintained until the silicone has cured.

Compression and injection molding are similar in that they fill a preformed cavity, but they are different in that compression molds are prefilled directly with the charge, while in injection molding, the charge is injected into a previously fully closed cavity.

Manufacturers of different types of parts often use both compression and injection molding but for different types of parts. Generally, injection molding is preferred for making more complex (and often smaller) parts, while compression is very efficient for simple or basic designs and large parts that cannot be produced using extrusion techniques.

Other points of comparison include the fact that Injection molding has a shorter cycle time and so is often faster and more cost-effective for large volumes, while compression molding is mainly used for low and medium production series of parts.

The main advantages of compression molding processing include:

- Very little waste of material providing

- Cost-effective, especially for large parts, but sometimes requiring post-mold finishing processing due to unequal product consistency and some flashing (gaps not always fully hollowed in grid patterns)

- Useful for some very large parts that cannot be made with extrusion molding

- Excellent for curved parts and useful for designing aesthetically creative parts, widely used in the automotive industry, often replacing metal parts to lower weight and save energy

- Used in several industries, including keypads for computers, kitchenware, electrical parts and some medical and dental devices.

Silicone rubber transfer molding

Higher mold temperatures can reduce the time needed for peroxide curing, but there’s a trade-off since these HCR parts can tear when removed from the mold. Unlike LSR injection molding, loading and de-molding are performed by an operator. Labor costs are also incurred during trimming since HCR molded parts may require surface improvements.

How does the HCR injection molding process work and what advantages does it produce?

A measured amount of HCR is injected directly from a cylinder through a screw mechanism and a nozzle into a closed heated mold, through a gate. The material fills and packs the cavities of the mold to form the part.

The main advantages of HCR injection molding include

- Short and accurate molding cycles

- Lower unit costs

- Low waste of material

- Possibility of mixed molding with other materials, such as plastics or metals

- Consistent production, in terms of finished products

- Superior precision and filling for complex parts compared to, compression or transfer molding.

- It is arguably the most common and robust molding method, in which the product can vary greatly in size, complexity, and application.

Conclusion

Jution Silicone works with you to define which materials are best suited for the intended application and processing conditions. Our technical team has expertise with all our HCR material and Liquid Silicone Rubber (LSR) materials and can advise you in your choice and all along your silicone products development.

Related Blog

-

The Silicone Toys for Kids and Adult -Pop-it

The Silicone Toys for Kids and Adult -Pop-it What is Pop-It silicone toy? Pop-It is a molded silicone toy that mimics the feeling of squeezing and has become a popular toy in elementary schools across the United States in recent years. The toy’s simple design allows users to experience the sensation of bouncing back by

-

The safety and cleaning methods of silicone baby toys

The safety and cleaning methods of silicone baby toys As a professional who has been deeply involved in the field of silicone materials for many years, I am well aware of the importance of safety and cleanliness of infant and toddler products. Due to its unique diversity, silicone baby toys have become an ideal choice

-

The baby’s first water cup Recommended

The baby’s first water cup Recommended Over the years, I have witnessed how silicone materials have reshaped the landscape of maternal and infant products with their unparalleled safety and functionality. The “first water cup” is an important tool for babies to transition from breast milk or bottles to independent drinking. At this time, our top

-

Silicone vs. Plastic Why are silicone baby products more recommended

Silicone vs. Plastic Why are silicone baby products more recommended As a professional with many years of experience in the silicone material field, I’ve witnessed how silicone, with its unparalleled safety and functionality, has reshaped the landscape of maternal and infant products. In this age of information overload, the sheer variety of baby products available

-

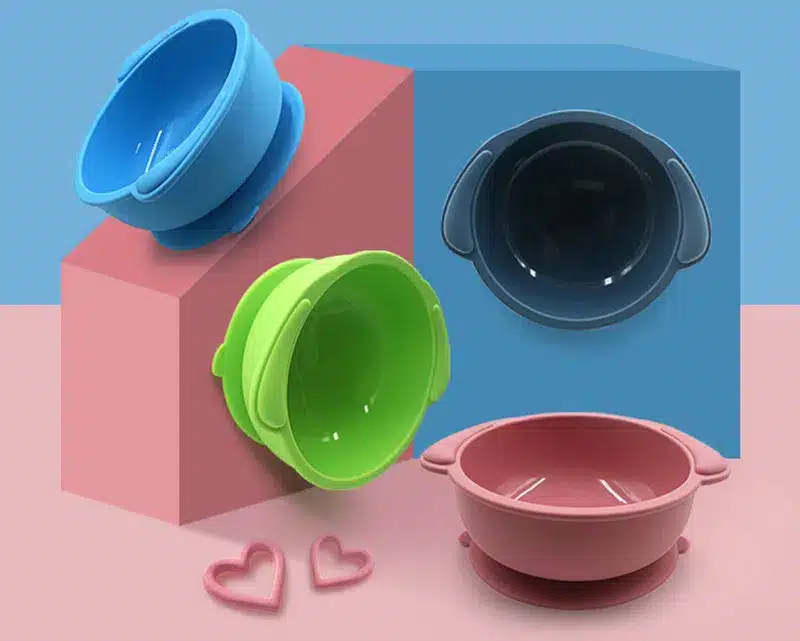

Silicone bowls vs. plastic bowls Which one is the best choice for babies

Silicone bowls vs. plastic bowls Which one is the best choice for babies As a professional who has been deeply engaged in the field of silicone materials for many years, I have witnessed how silicone materials have reshaped the landscape of maternal and infant products with their unparalleled safety and functionality. As a person with