Silicone baby Molding Products Quality Control and Standards

How we use digital processes, scientific silicone molding, and inspection reporting to manufacture quality silicone products consistently

- Manufacturing analysis

- Scientific molding and process qualification

- Critical to quality reporting

Producing high-quality silicone molded products consistently requires a combination of in-process inspections and controls and dimensional verification after production. Designing the silicone part with the manufacturing process in mind is the first step in ensuring a quality molded part. That’s why we provide design analysis with every silicone molding quote. Getting manufacturing analysis early in the molding process can help eliminate costly redesigns, save development time, and take the guesswork out of the molding process. Before placing an order, you’ll know if your design requires any changes, get recommendations to improve its moldability, and see other useful information to understand how the final part will be molded.

Design for Manufacturing (DFM) Analysis

When requesting a quote through our online quoting system, you will receive manufacturing analysis and pricing. The first step in the digital manufacturing process can enable customers to test multiple designs simultaneously, thereby arriving to design validation sooner, which saves time in the development cycle.

How our manufacturing analysis can improve quality of injection-molded parts:

Design Support from our Silicone Injection Molding Experts

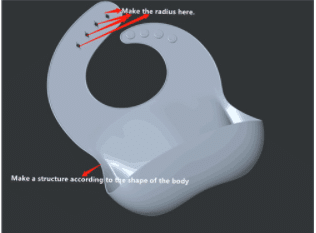

Consultative Design Services: Work directly with a silicone molding applications engineer to improve the moldability of your design. Think of it like having your very own silicone molding consultant on your team. During this process, our applications engineer will collaborate with you to understand your design goals, review the manufacturing analysis provided in your quote, and make changes to the 3D CAD file.

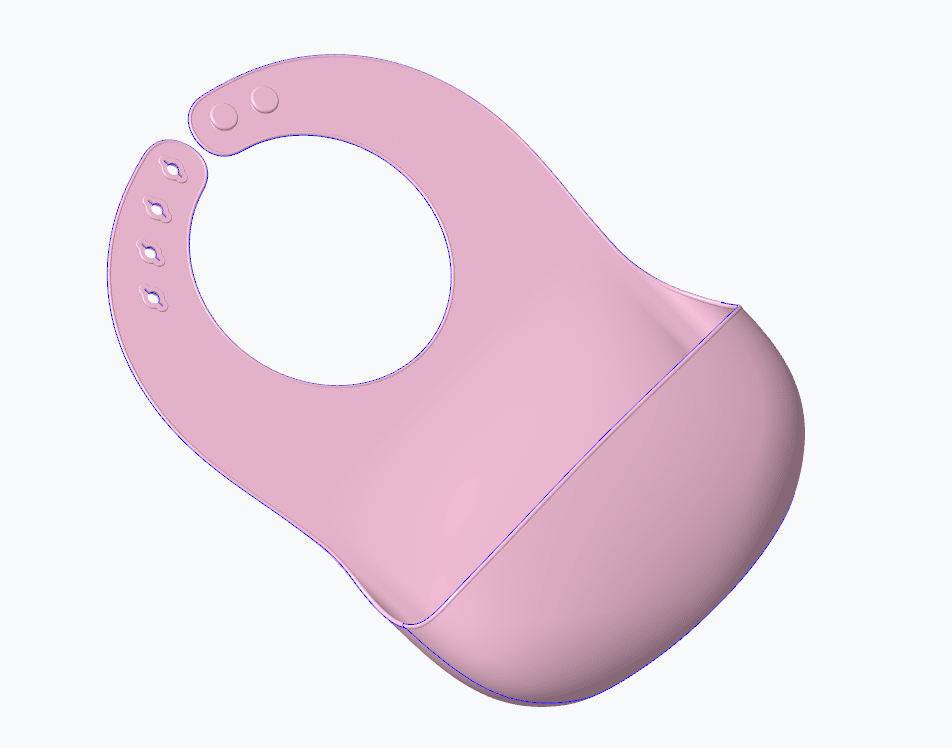

Jution Silicone Proposed Revision (PPR): In some instances, we can provide a second CAD model to you—called a Jution Silicone Proposed Revision (PPR). This is a new CAD file with changes already made. The revised model can be used immediately or you can transfer the modifications to the original model. Following the DFM analysis, and, in some cases, the PPR, once the products has been approved, Jution Silicone moves into the final step before actual production—the digital preparation.

Scientific Silicone Molding: Consistently Delivering Quality Silicone Parts

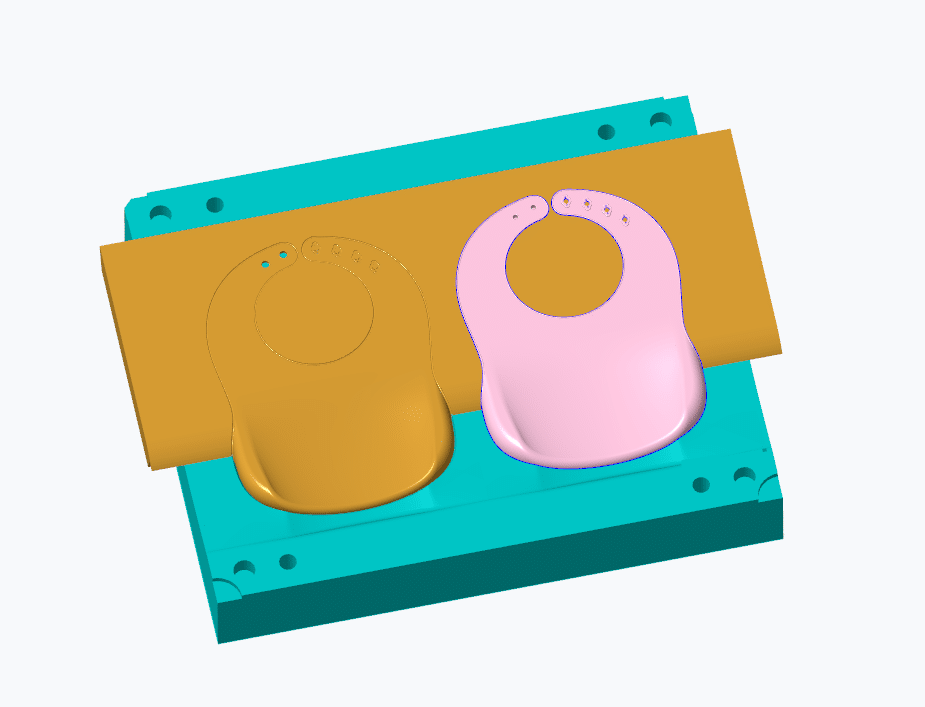

We use a scientific silicone molding process to manufacture consistent, repeatable parts for our silicone baby products molding customers. We develop, optimize, and document the ideal setup process for each injection molding project so that the same process and parameters are followed for every single run of a customer’s mold. Any modifications are documented to provide traceability across molding runs.

Whether the silicone products will be run again or on a different silicone molding press, or if it will be ordered once several months later, scientific silicone molding ensures part-to-part and run-to-run consistency by documenting the exact process used to set up the tool in order to meet the particular silicone material needs and dimensional requirements.

By following these industry best practices we can ensure that each silicone product has the same properties as the previous part, by controlling fill, pack, and hold. This results in two key benefits for our customers: more consistent silicone products that are of higher quality and inspection reports for qualification.

Our Critical to Quality (CTQ) Capability Report

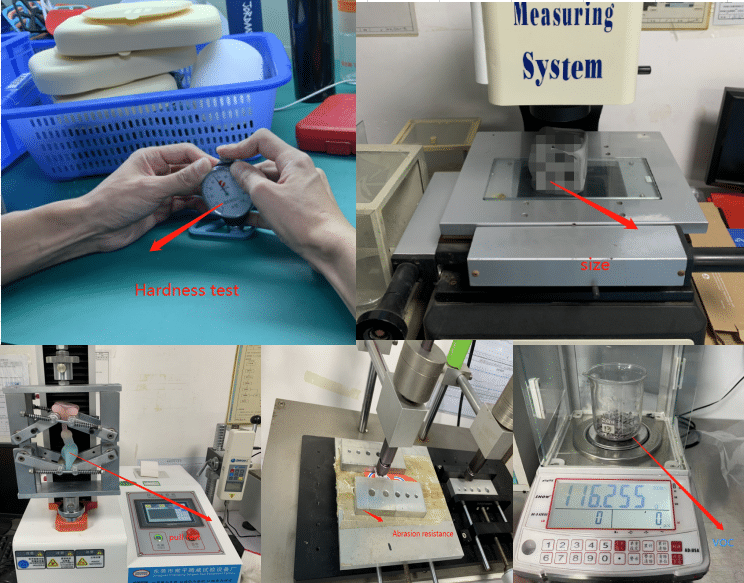

Jution Silicone&Rubber (Dongguan) Co., LTD the whole-process quality control system ensures that our customers can receive the qualified Silicone baby products as the prototype they approved before mass production.

Supplier Selection – Supplier Quality Assurance – IPQC

Product Specification- Customer’s needs, Check the Product Specification,Function, Certifications and Packing. Golden Samples for Customer’s Confirmation and for Future Reference

In-Process Inspection-General Quality Benchmarks Employee Involvement:Education and Training, Inspection in Each Process, Initial Sample Reviewed with Every Production Run.