Silicone Extrusion Molding

Silicone extrusion is a cost-effective continuous molding process. With extrusion, you can achieve high-volume product output in a relatively short period. Silicone extrusion is the process whereby silicone is forced through a shaped die (a stainless steel disc with a pattern cut out) to produce cords, complex profiles, and cross-sections.

The silicone material is thermally cured through specific molds and equipment to form the required cross-section, complex contours, and continuous lengths.

Silicone rubber that is used via extrusion molding, either precipitated or fumed, is widely preferred as a material for various applications. This process is especially suitable for the production of unrestricted tubular or strips of silicone rubber products, such as:

- medical silicone tubes, silicone wires, sealing strips, gaskets, or other complex-shaped products.

- Extruded parts for industrial use and technical use, like silicone tubes, profiles, strips, electric cabling, etc.

- Food contact products that complied with FDA 177.2600.

Custom silicone extrusions service

Jution Silicone can manufacture custom silicone extrusions in an endless combination of designs, sizes and colors. We work directly with companies all around the world in order to provide the quickest and highest quality service. We also tailor each profile and production run to suit your exact requirements. This ensures that your extrusion is always suitable for use.

We manufacture using a high-quality silicone rubber compound due to the unique combination of properties the material provides. Silicone provides great flexibility as well as high levels of strength and tear resistance. It is also able to maintain these physical properties across a wide operating temperature range. Silicone features high levels of resistance against a variety of common chemical solutions. This makes it ideal for use in hazardous and sensitive environments.

Our Extrusion Molding process produces custom prototypes and end-use production parts in 7 days or less. We use AL molds that offer cost-efficient tooling and accelerated manufacturing cycles, and stock various grades and durometers of Solid materials.

Get Custom Multi-colored silicone rubber baby products within days.

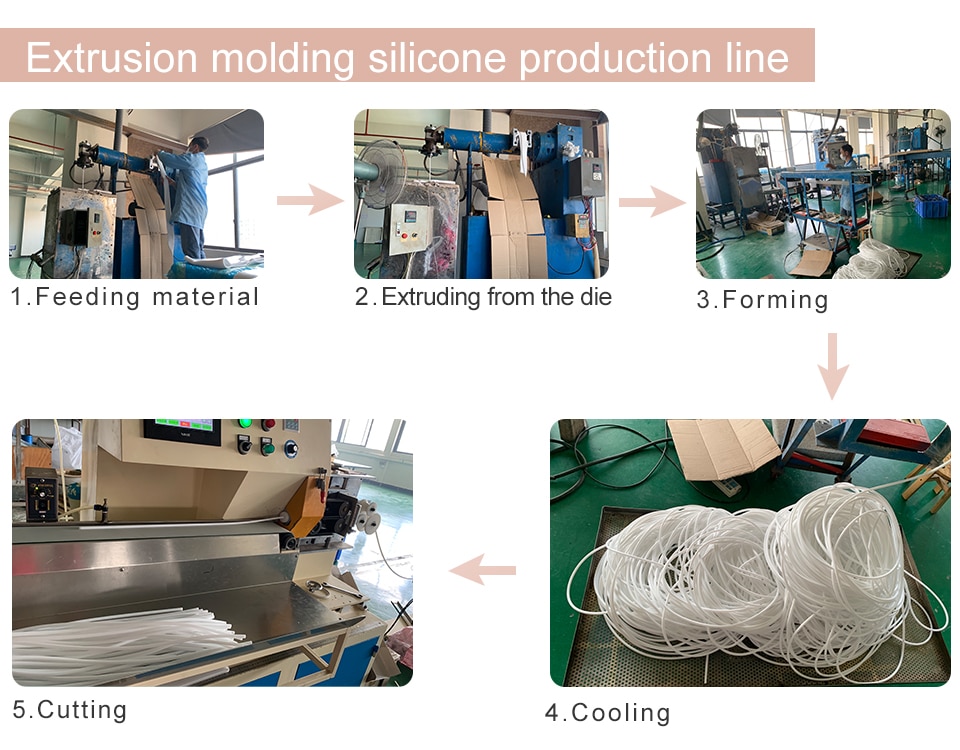

Silicone extrusion process

Silicone extrusion is the process whereby silicone is forced through a shaped die (a stainless steel disc with a pattern cut out) to produce cords, complex profiles and cross-sections.

Thanks to advances in production capabilities over the last 30 years, the custom silicone extrusion process has become more accessible. Subsequently, silicone has become the go-to elastomer for use in engineered products.

We regularly supply engineers, manufacturers, and inventors with tubing, cords, and bands, as well as more complex profile shapes or molded products from solid silicone and other elastomers. In addition to that, we also produce open-cell or closed-cell silicone foam.

Using the extrusion process, the finished product can be manufactured in continuous lengths or cut to length and packaged to meet the customer’s usage needs. Lastly, we can imprint your product information, logos, or graphics on the finished product.

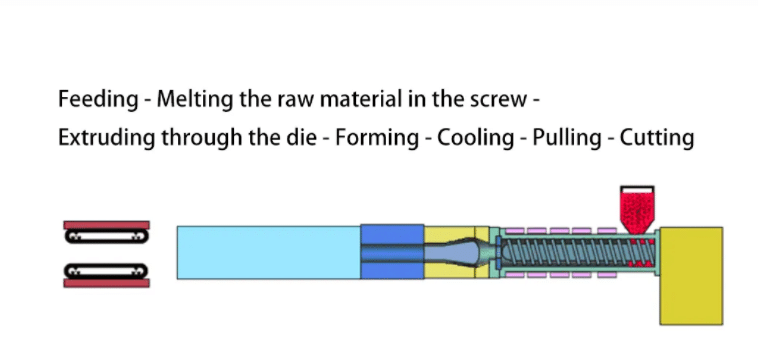

Principle Of Extrusion Molding

First, the pretreated silicone raw material enters the extrusion machine, and under the action of high temperature and high pressure, it is output into a continuous silicone strip, whose shape is determined by the die and extruder head on the machine. After that, the silicone strip will be repeatedly Pulled and heated several times to achieve the purpose of curing.

Most customers are keen to use a silicone extruder to extrude silicone into regular-shaped silicone products in plates, tubes, or strips. The finished product produced by this method can be cut arbitrarily. Due to the difference in process and process shape, the application of extruded silicone products is mostly in the fields of medicine and food machinery.

Advantages of Extrusion molding

Extrusion is among a few processes that are remarkably similar for silicone. silicone extrusion has a plethora of advantages, and the following are a few of the main ones:

Extrusion is a great choice for basic silicone product production but has a lot of disadvantages as well. Here are some examples:

Part-size Deviations

One of the key limitations of the extrusion process is its inability to handle deviations in the cross-section or size. Any change would need a separate tooling, which can potentially cause delays.

Typical Shapes Of Extruded Products

Typical Properties Of Extruded Silicone

Biocompatibility

Silicone is non-toxic and non-allergenic, which makes it unlikely to cause negative reactions with human tissue when used in medical devices and equipment.

Resistances

As an inert material, silicone does not react with most chemicals or other materials. Silicone resists most bases, ultraviolet radiation, ozone, water, and oil. It also inhibits the development of molds and fungi.

Dielectric strength

Extruded silicone materials act as good electrical insulators and won’t degrade under typical exposure to current.

High-temperature resistance

Most common silicone extrusions can deal with temperatures as high as 500°F. Silicone extrusions are also flame retardants.

Elastic memory

Silicone extrusions feature excellent elastic memory, ensuring they will maintain or return to their original shape after exposure to high pressures or compressive forces.

Transparency

Extruded silicone’s relative clarity makes it easy to color or use in clear tubing.

At Jution Silicone, we pride ourselves on our ability to design custom silicone extrusion products to meet virtually any need. Our manufacturing processes adhere to many industry standards, such as FDA 26CFR, ISO 9001:2015, ASTM, ITAR, Buy American Act, WOSB, and MILSTD-105e. We can also develop unique formulations to meet specific application requirements.

For further examples of our work, please review some of our case studies. If you are interested in working with us, please request a quote or contact us.

Compare our Silicone Molding Manufacturing Services

| Silicone Rubber compression molding | Liquid Silicone Rubber (LSR) Injection Molding | Silicone Dripping Injection Dispensing(co-injection) Molding | Silicone Over-Molding | Silicone Extrusion Molding | |

| Material | Solid Silicone Rubber | Liquid Silicone Rubber | LSR and SSR | Silicone Rubber, Plastic, Metal | Solid Silicone Rubber |

| Mold | Compression mold | Injection mold | Dripping Injection Dispensing mold | Compression mold and Injection mold | Extrusion Mold |

| Molding process | Compression | Injection | Dispensing and compound | Overmolded | Extrusion |

| Mold Cavities | Single and multi-cavity | Single and multi-cavity | Single and multi-cavity | Single and multi-cavity | Single |

| Mold Life | Around 50000 | unlimited | unlimited | unlimited | Around 50000 |

| Colors | Single color | Single color | Multi-color | Colored or Single Color | Single color |

Advantage:

Application:

Read More:

Injection Molding VS Compression Molding

Injection Molding vs Extrusion Molding

Custom Silicone Extrusion Molding Solutions For Your Business

Are you Searching for a new silicone baby products factory either to make a mold for your next product or a factory that provides a complete service (silicone mold + production and packing)? Jution Silicone is your choice.