Prototype and Mold Development Service

After you confirm the 3D drawing. You may need make the prototype to see them in reality. Here we offer you 2 methods: Rapid Prototype or Classic Mold Making. Here we offer you 2 methods: Rapid Prototype or Classic Mold Making.

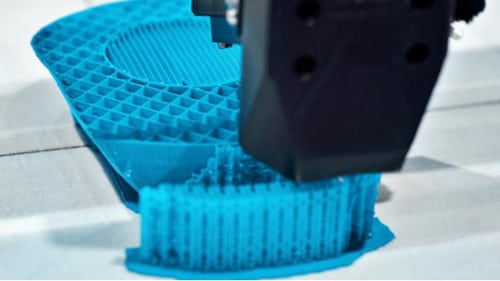

Silicone Rapid Prototype

Rapid Prototype Mold Making

Rapid Prototyping is an important step in the design development and approval process leading to higher volume serial manufacturing. Speed, cost, and approximation to the final silicone product design (including material properties and dimensions) are key criteria when selecting a fabrication method for making a silicone prototype.

For silicone products, there are 4 ways to make the product development process for silicone products. Available processes for making silicone prototypes include:

Silicone Rapid Prototyping Comparison

| Method | Description | Speed | Approximation to Production |

|---|---|---|---|

| SLA/FDM | 3D printing, Part is formed layer-by-layer from raw material. | No tooling 1-25 parts: 1-2 days 25+ parts: Multiple days | Low: Shapes are similar, but material likeness has limitations. Typically has a “cloudy” finish. |

| RTV | Material is injected by hand at low pressure. Cures at room temperature with various mold choices. | Tooling: Days to weeks 1-25 parts: Multiple days 25+ parts: Days/weeks (due to cure times) | Medium: Silicone parts with an accurate durometer, but the manufacturing process might differ. |

| HCR | Transfer molding with mold materials mainly metals. | Tooling: Fast 1-25 parts: 1-2 days 25+ parts: Multiple days | High: Silicone parts with accurate durometer. The manufacturing process is typically the same as production. |

| LSR | Injection molding with mold materials primarily metals. | Tooling and parts: 3-7 days | High: Silicone parts with an accurate durometer. The manufacturing process is typically the same as production. |

Classic Mold Making

We can directly develop a silicone mold to make the Prototype. Here are the steps:

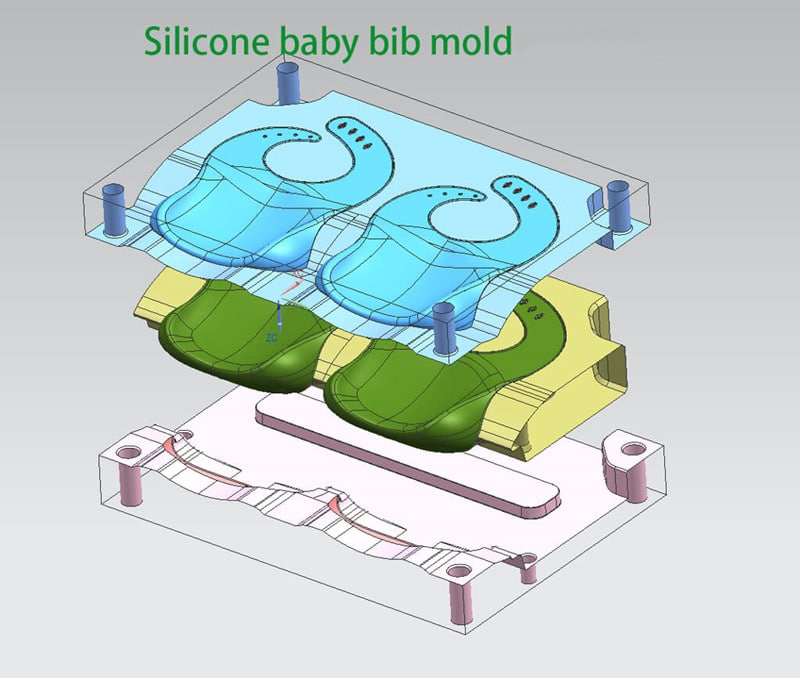

Step 1: Mold Design and Manufacturing

Well-designed silicone mold optimizes its productivity of the silicone mold.

We offer our customers real molded silicone baby products by producing a “sample tooling” with only 1 cavity around one week.

So, mold design is our first step in prototyping. It is crucial to create a baby product with high manufacturability. Good mold design for each can contribute to improved silicone baby products quality and optimum cycle time, and optimize the productivity of the mold.

Our engineers are silicone tooling and mold makers with decades of experience designing the most robust and innovative tools in the industry. Contact our silicone tooling experts to get your silicone creation prototype.

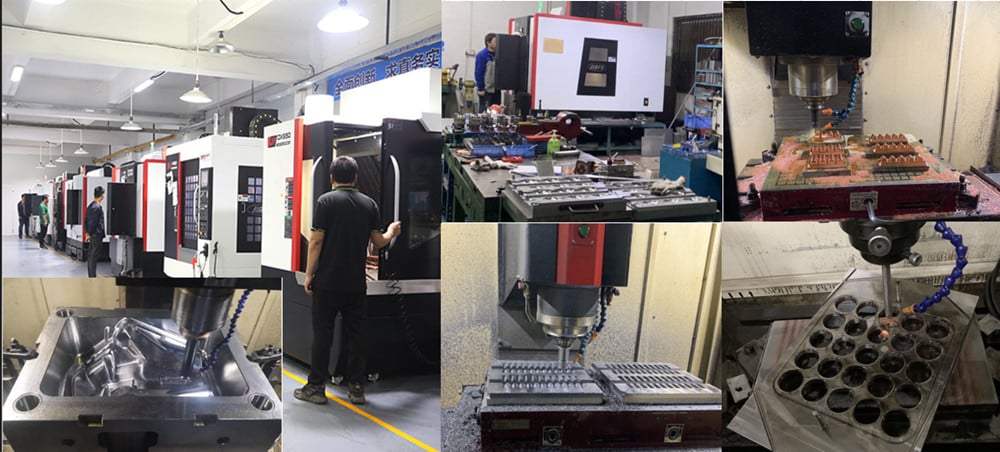

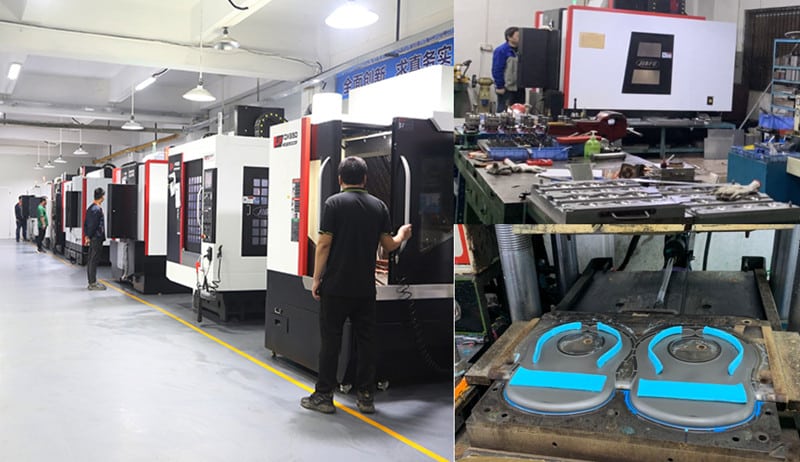

Step 2: Silicone tooling mold workshop

In-house Silicone tooling mold workshop help simplify the product development process

Our CNC milling and machining bring your 3D drawing into the physical world. Jution Silicone & Rubber (Dongguan) Co., LTD has an in-house tooling shop. Then we can make your silicone baby products tooling with initial precision tooling and any future adjustments in our tooling workshop. This means that potential mold adjustments are more affordable and reduce turnaround times.

Not only do our experienced machinists offer unparalleled insight into a mold design, but adjusting a mold once created is more cost and time-effective with our in-house time. Additionally, we are able to reduce mistakes and lead times with our in-house machine shop.

Jution Silicone & Rubber (Dongguan) Co., LTD ’s in-house tool shop consists of 21 latest state-of-the-art 3-axis CNC machines and 5 EDM machines. Our proprietary CNC milling and machining processes enable quick turnaround and beat your deadlines with our quick-turn CNC machining.

Our precision silicone tooling mold shop is devoted to customers hoping to create a custom silicone baby product. Seek a silicone tooling maker/molder and silicone baby products manufacturer for creating silicone baby products.

Step 3: Silicone mold tooling surface processing

Surface processing can improve tool performance & life span and enhance silicone baby products appearance

Proper treatment of the mold’s surface is key to silicone baby product quality, product hand comfortability, appearance, corrosion resistance, tool life, increase performance, reduce wear, etc.

At Jution Silicone, widely applied tool mold surface treatments during silicone product development include:

At Jution Silicone, our in-house mold design & manufacturing help simply the silicone product development process. If you have a great idea, we can help bring it to life. Start your custom silicone baby project today.

Step 4: Sample Prototype Making

This step brings your design into a real product that you can check and test.

Once the silicone baby products tooling is finished, we will be able to produce physical prototypes for confirmation. We will check the functionality and critical dimensions before we ship the products to customers for inspection and additional testing.

Customers are able to see their concept, and idea in a handheld product that allows them to see, touch and test the function. Necessary adjustments can be made as required. We will conduct a second mold revilement, and again ship improved silicone baby products to you for inspection, as required.

Please note that once our silicone baby products mold and products meet the customer requirement, but the customers request product changes for their reason, requests can normally be accomplished, but need the customer’s to pay the modification cost.

From Concept Design to Working Models. At Jution Silicone we not only help with your prototypes, but also with industrial design, engineering, and manufacturing. Have a new silicone baby product idea and need it prototype d and manufactured? Welcome to contact us.

Step 5: Custom LOGO and Branding

Put your logo and Build your brand identity

The logo is an easy way to spread your brand, let people know, and find you more quickly. Jution Silicone offers branding services for logoed corporate silicone baby products.

For silicone baby products, there are 3 ways to put your logo on silicone baby products:

- Debossed or embossed LOGO on tooling mold directly

- Etch or laser engraved LOGO

- Printed LOGO

Debossed Logo Silicone Baby Bibs

Embossed LOGO Baby Bibs

Laser Engraved LOGO baby bibs

LOGO Silicone Baby Bibs

You can check here or contact us for more information.

Jution silicone can help our partners with customers through the entire development process. We offer 3D printing, compression molding, transfer molding, and LSR molding. Our focus is on your final manufacturing method and our ability to quickly deliver a prototype manufactured using that method.