Silicone Product Design & Engineer Support Service

We provide silicone product designs for our clients. We work with product development managers, designers, and offer you well-designed, manufacturing custom silicone baby products and production expertise.

Step 1: Needs and Cooperation

When you come to us with a new product idea or a draft to create fun, safe, and innovative baby products. Communication and creating the 3D drawing for the baby products is the first!

We support our customers early in the product design stage, sharing valuable suggestions to optimize the custom silicone baby products design for manufacturing and enhancing the product’s final functional performance. We will try to insure all the silicone baby products what you designed can pass the third-party physical test. eg: tension test, choking test.

Our engineers will serve as an extension of your products design team, working together early to gain a comprehensive understanding of your baby products needs and their components.

With thorough commutations about your needs, goals, and requirements for your silicone baby products.

Our design and manufacturing engineers will work with your team to make sure the design meets processing requirements and can be produced consistently and cost-effectively. Lastly, our engineers will work out the 3D files after a mutual agreement on the final design.

A detailed design concept review ensures we fully understand your specific design, engineering, and manufacturing needs.

Mutual communication by email, WhatsApp, WeChat, etc. can help you save time and money when you are designing a custom-made silicone baby product by getting involved in the early stages of silicone baby product development. From concept to product launch, our engineers ensure that every silicone baby project is designed for success.

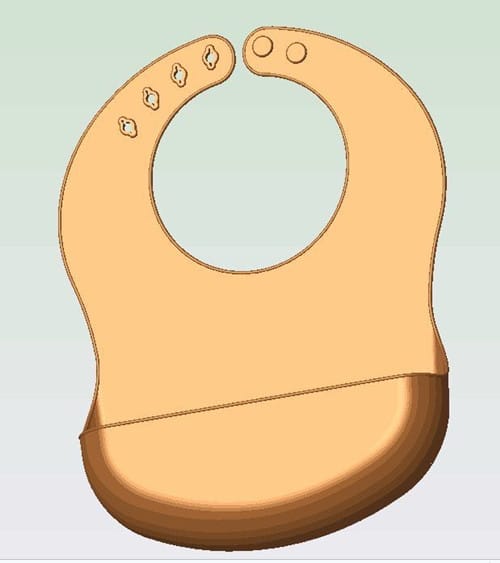

step 2: Silicone baby project design Draft and 3D drawing

Our skilled engineers will work collaboratively with customers at an early stage of customized silicone baby products design. With thorough communication, our engineers will work out the 3D files after a mutual agreement on the final design. 2D or 3D CAD Moldeling will be sent to customer for review to double check if anywhere need to be revised. From the drawing, customer can see:

We provide innovative solutions to bring new products to full production. Looking for a silicone baby products manufacturer to creat a custom silicone baby product? Contact us today.

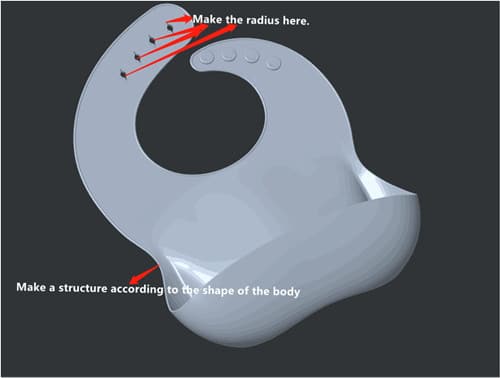

Step 3: Design for Manufacture (DFM) and Design Adjustments

It is important for our engineer team to see a finished 3D part design before a custom silicone baby products piece quote. The 3D drawing can be in the formats of STEP/STP, IGES/IGS, PRT, X_T, and SLDPRT.

For customers with existing 3D silicone baby products design, an important consideration in silicone baby products design optimization is DFM (Design for Manufacturing).

Our professional engineering team will undertake a thorough, engineering-oriented analysis of your baby product – digging into the details to suggest design changes to ensure an enhanced baby products design, optimized molding process, and superior quality.

We perform full DFM analysis on all custom silicone baby products projects. Want to know about the manufacturing process and the design manufacturability of OEM design silicone baby products? Welcome to contact us.

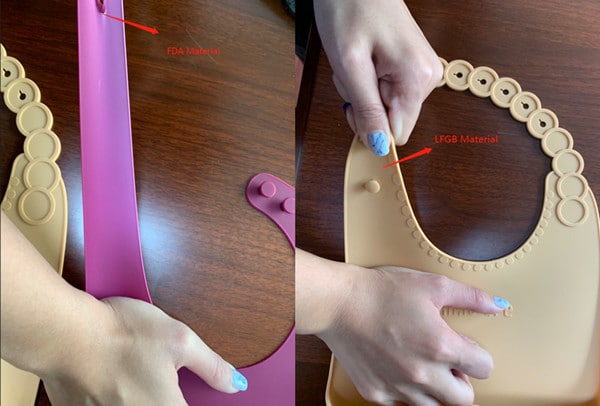

Step 4: Material choose and Color Matching

Material Recommendation

Silicone rubber materials are formulated into so many different types, so choosing the best fit material is crucial to your baby project’s success.

Please inform us in advance of your specific application needs, so we can recommend the right material for your cases.

FDA and LFGB Material and permanence

Color matching

When we first see a product, the first thing that comes into our eyes is color and contour. Therefore, product color matching must be placed in a very important position in the product design process! Different colors bring different feelings to customers. Our color matching includes:

- Pantone Match: Choose a color from the PANTONE® book or online PANTONE® color chart. Please choose a color from formula guide or solid coated (color number ended with the letter ‘C’ ).

- Physical Match: Any physical items you find lying around can be matched to a specific pigment and color. You can send the color sample to us, our professional color master can work out the color formula 99% match with your sample.

Jution Silicone & Rubber (Dongguan) Co., LTD has experts who can help you select the materials and color of your tailor-made silicone baby product, creating the perfect combination of both. Meet our experts today.

Step 5: Cost

Cost is one of the important factors to be considered when designing silicone baby products.

During the new product design phase, our engineer will also discuss with your team your target price and annual expected product volume. The price can vary depending on silicone baby products’ size, weight, and complexity.

Our engineers will make recommendations including material selection, structure analysis, mold cavities, surface finish, and branding ways within your budget.

Would you like to get pricing on developing and producing a custom silicone products project? Let’s talk to our engineering team.