Custom Silicone Compression Molding Service

Transform Your Design Into a Masterpiece with Our Custom Silicone Compression Molding Service – Precision, Quality, and Excellence at Your Fingertips!

What is Silicone Compression Molding?

Silicone Compression Molding is a high-precision manufacturing process utilized to fabricate intricate, durable silicone components. Esteemed for its versatility and cost-effectiveness, it is often chosen for producing parts with complex geometries, tight tolerances, and high-quality finishes across a multitude of industries.

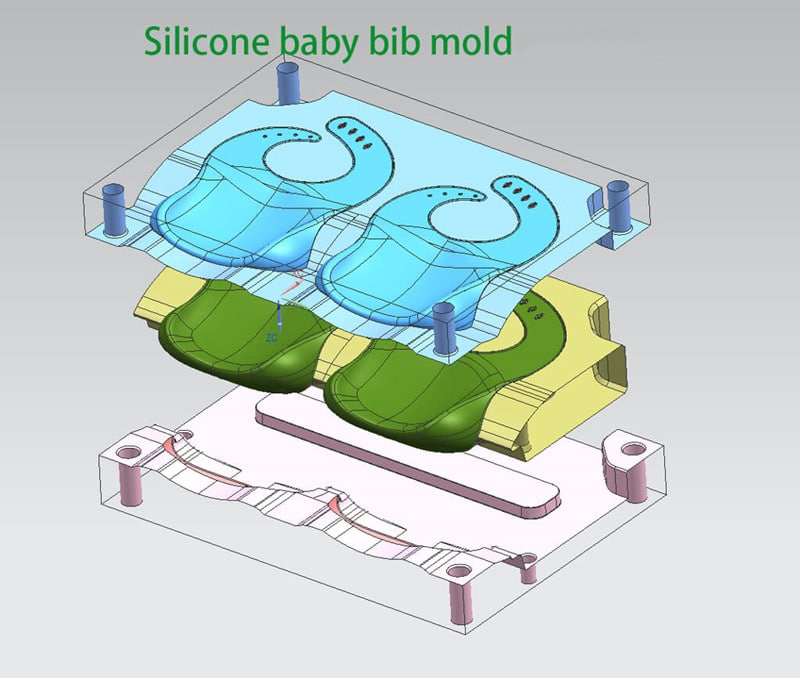

At the core of the process is the compression molding technique, which applies heat and pressure to cure and form silicone material into the desired shape. The process begins with a high-consistency silicone rubber, often pre-formed into a shape approximating the final component, known as a preform.

The preform is placed in an open, heated mold cavity that precisely mirrors the design of the final component. The mold is then closed, and pressure is applied, forcing the silicone to fill the mold cavity. Concurrently, the heat initiates the curing process, transforming the silicone into a robust, flexible material. Upon curing, the mold is opened, and the formed silicone part is removed.

Recommend Reading: Silicone Compression Over-molding

Advantages of Silicone Compression Molding

Silicone Compression Molding offers several advantages, making it an attractive option for many applications. It’s well-suited for both low and high-volume production runs and can efficiently handle a wide range of product sizes and complexities. The process permits the use of high-viscosity, high-strength silicone rubber, allowing the creation of products with exceptional durability and resilience.

Moreover, Silicone Compression Molding enables the production of parts with excellent dimensional stability, which is crucial when tight tolerances are required. It also facilitates the manufacturing of parts with intricate designs or multiple cavities, which might be challenging with other molding techniques.

Further Reading: The difference between Compression Molding VS Injection Molding in terms of the Definition, manufacturing process, materials used, production rates, cost, and application.

Applications of Silicone Compression Molding

Applications of Silicone Compression Molding span across industries such as medical, automotive, electronics, aerospace, and consumer goods. The process is often used to create seals, gaskets, keypads, electrical connectors, and many other products.

- Medical Devices: Silicone Compression Molding is employed extensively in the medical sector due to silicone’s biocompatibility and durability. The process is used to produce components such as seals and gaskets for medical devices, silicone valves, and even specific parts of implantable devices. As of 2021, the global medical device market was valued at approximately $450 billion, and silicone components play a crucial role in many of these devices.

- Automotive Industry: Silicone compression-molded parts such as gaskets, seals, and hoses are integral to the automotive sector. These components help ensure vehicle reliability and safety by withstanding extreme temperatures and resisting various automotive fluids. The global automotive silicone market was estimated to be around $3 billion in 2020, reflecting the significant use of silicone in this industry.

- Electronics: Silicone’s excellent electrical insulation properties make it ideal for electronic applications. Silicone compression molding is used to manufacture keypads, connector seals, and insulation pads for electronic devices. With the global consumer electronics market size projected to reach $1.5 trillion by 2027, the demand for silicone components is expected to remain robust.

- Aerospace: In the aerospace sector, where components must withstand extreme conditions, silicone compression molding is used to create seals, gaskets, and insulation parts. These components must be highly durable and able to resist temperature fluctuations and exposure to various chemicals. In 2019, the aerospace and defense market was valued at $384 billion, underscoring the considerable role of silicone components in this sector.

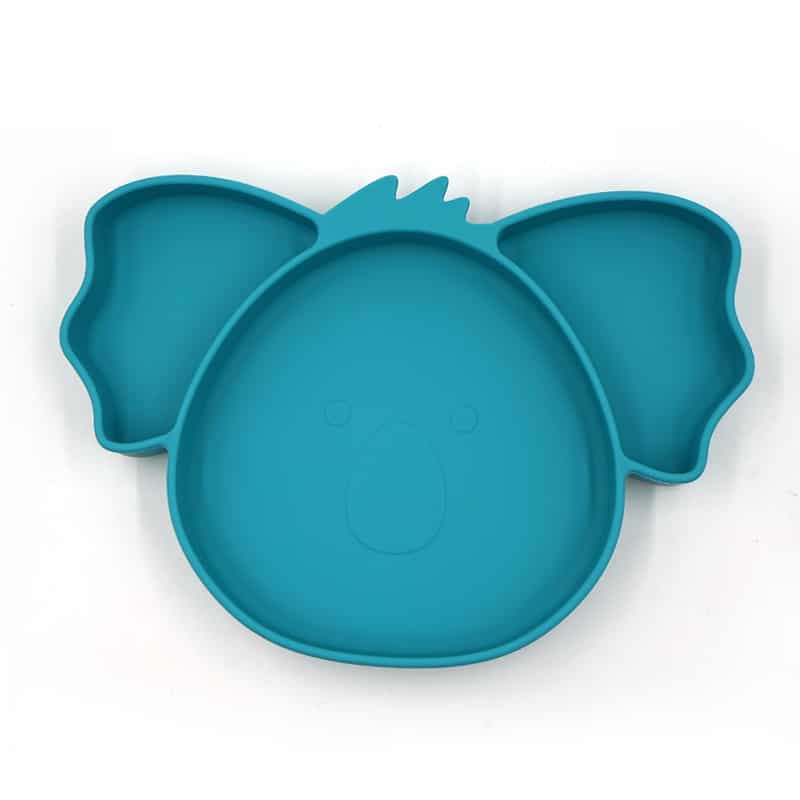

- Consumer Goods: The process is also used in the manufacture of consumer goods, like silicone kitchen utensils, watch bands, and wearable technology. The global market for silicone in consumer goods was valued at over $7 billion in 2020, reflecting its widespread use in everyday products.

Our compression molding process produces custom prototypes and end-use production parts in 7 days or less. We use AL molds that offer cost-efficient tooling and accelerated manufacturing cycles, and stock various grades and durometers of Solid silicone materials.

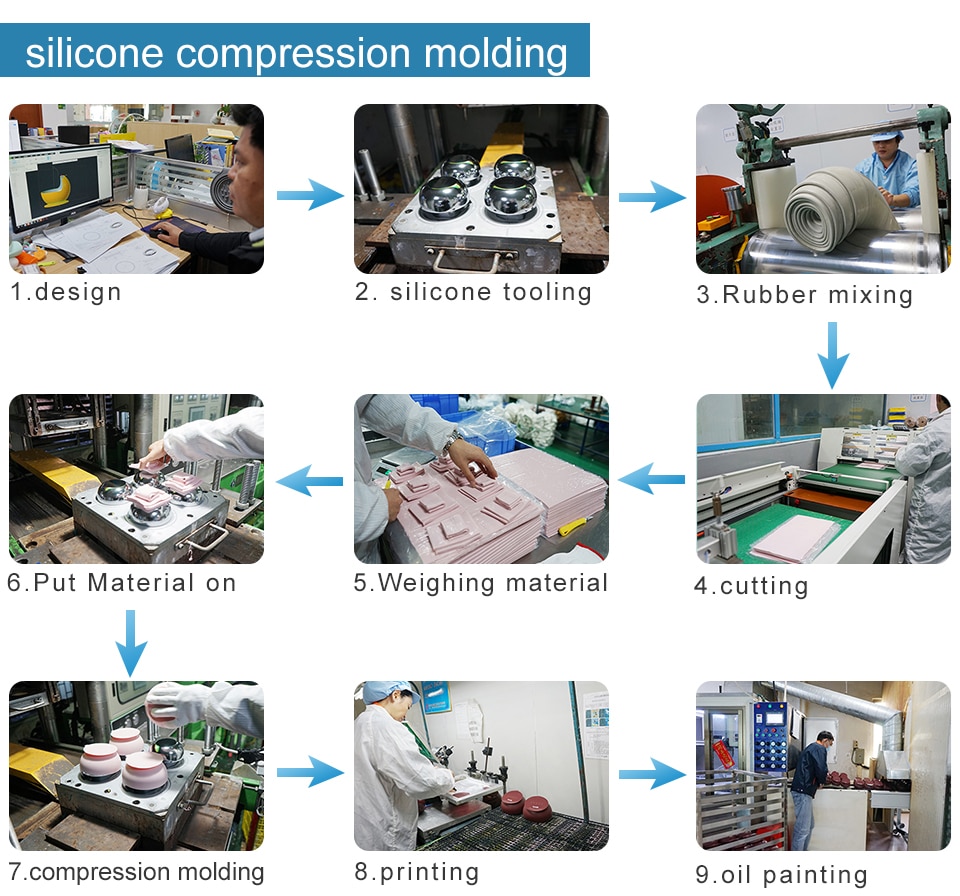

Process of Silicone Compression Molding

Detailed Process

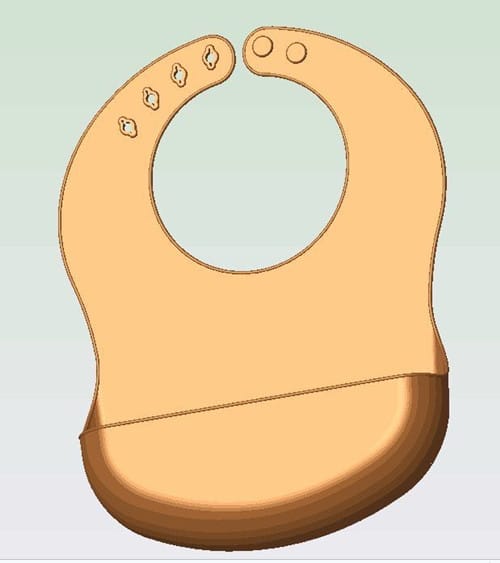

Step 1: Choose silicone material

The silicone molding production process begins with silicone raw material selection. Silicone rubber materials are formulated to meet different application needs, so they are divided into Different Options. Choosing the right silicone material when manufacturing a new silicone product is vital for its success.

By understanding the client’s needs properly, we will recommend the best silicone material. Based on product structure/function, application environment, performance, safety test requirements,s and customer’s budget, the most feasible material will be selected.

Step 2: Adding pigment

Silicone raw material itself is a milk-white or transparent gum-like component with no elasticity and strength. To improve the characteristics of raw silicone material and to have the desired color, silicone material will be compounded with many ingredients such as vulcanizing agent, reinforcing filler, accelerator, colorant, etc.

Silicone compounding is the complex technology of selecting and blending silicone with other ingredients. The proper mixture is crucial to the success of silicone molding production.

Step 3: weigh and shape

Once the material has been pre-catalyzed and pigment has been added, technicians will then weigh it and shape it to match the needed size and configuration of the part in question.

Silicone material after blending will be collected in large rolls covered with film to prevent dust or dirt. It then will be cut into slices by an automatic cut machine. The slices’ length and width will be controlled according to the silicone part’s weight to be molded. Silicone blanking makes it easier for our molding operators to weigh the material during silicone molding production.

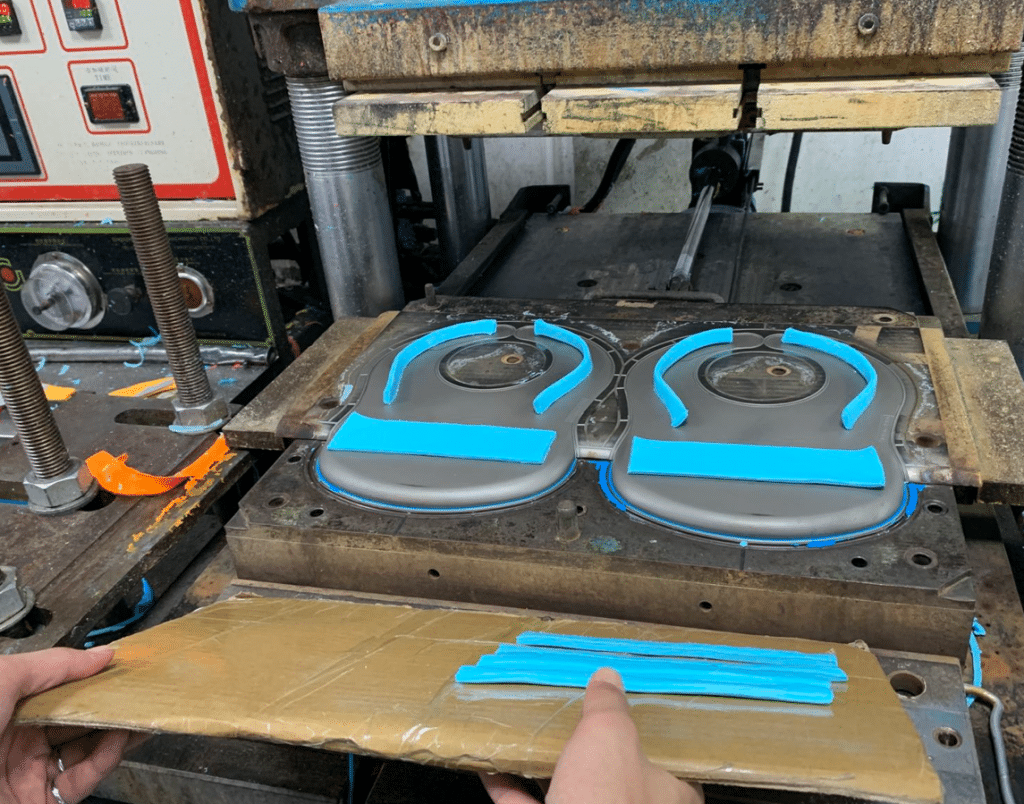

Step 4: put it into the mold cavity

Put it into the mold cavity for formation, compressing the silicone between the top and bottom plates.

The plates are then heated to melt and cure the silicone. The heat and pressure will last for a few minutes until the raw material is fully cured, this process is also known as silicone vulcanization.

Molding operators should be able to cut slices into small pieces and weigh them accurately, then place them quickly onto the tool mold in right place. Material weight is crucial, as too much material will lead to silicone parts size increase, and a lack of material will cause a small size or missing part.

Jution Silicone offers standardization training to each molding operator, all our molding staffs have at least 3 years of work experience in silicone molding production. Their years of experience allow them to solve any manufacturing problems in silicone molding, and ensure reliable and high-quality outcomes.

Put Material Into The Mold Cavity

Step 5: vulcanization molding

The silicone material will be fully cured under high temperature and pressure from vulcanizing molding machine, then the silicone parts are formed.

Our molding department is equipped with 36 high-precision automatic vacuum vulcanizing machines which can be used to craft more high-performance silicone parts. Our sophisticated molding machines, coupled with our skilled operators, provide the capacity and flexibility to mold high-quality, high-volume silicone parts in a short period.

Step 6: demolded

When the silicone is fully cured, the vulcanizing molding machine will release the pressure automatically, tool mold will come out and open for molding operators to remove the molded silicone parts. The raw material will be placed again for the next round of vulcanization.

Step 7: Deflash

Silicone Flash – This is a thin flap of material at the parting line where the mold splits. Due to the low viscosity of silicone material and high molding pressure during heating and curing,

The pressurized silicone material will flow to every space of the tool mold. Flash can be minimized with favorable designs and better tooling and accurate material weight during vulcanizer molding production. Flash will be removed mainly by hand, cryogenics deflashing can also be applicated for some cases.

Note that on all silicone baby products, there will always be a flash line with a small amount of silicone flash (less than 0.5mm) remaining, we call it a parting line. For some products which have a value much on outlook, the parting line may affect, so please inform us in advance, our engineer will design the mold layout in a better way during the mold design.

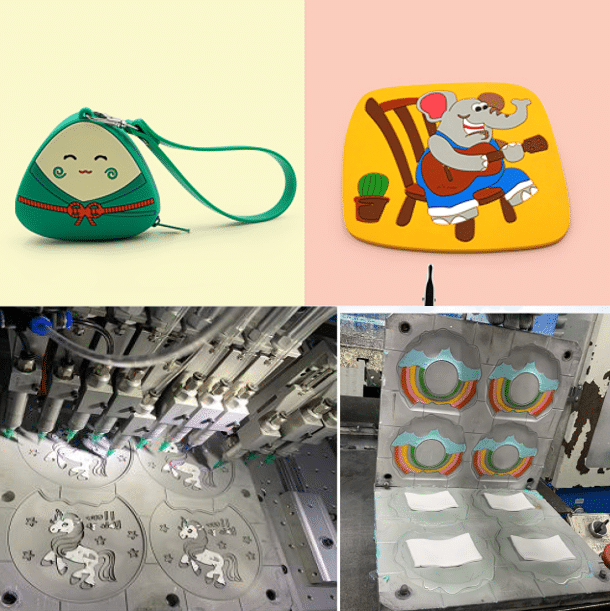

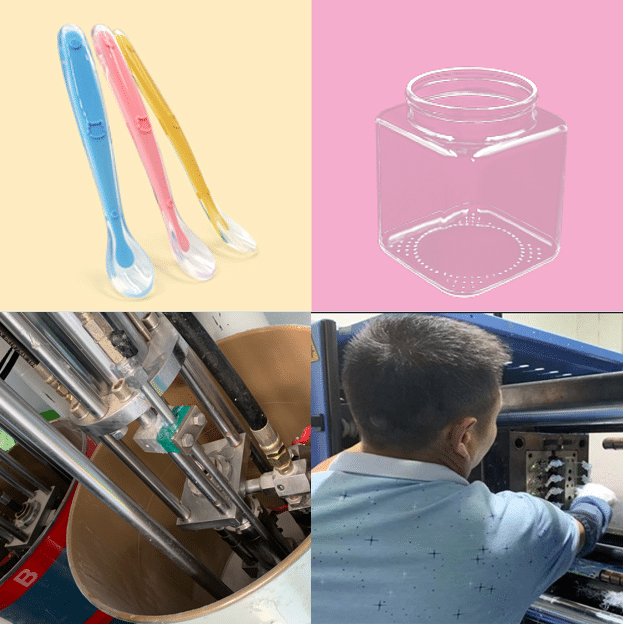

Custom Silicone Products using Compression Molding technics

The Comparison of Silicone Molding Services

Choose the Silicone Molding Service That Best Fits Your Unique Needs. Explore, Select, and Let Us Craft Your Vision Into Reality!

| Silicone Rubber compression molding | Liquid Silicone Rubber (LSR) Injection Molding | Silicone Dripping Injection Dispensing(co-injection) Molding | Silicone Over-Molding | Silicone Extrusion Molding | |

|---|---|---|---|---|---|

| Material | Solid Silicone Rubber | Liquid Silicone Rubber | LSR and SSR | Silicone Rubber, Plastic, Metal | Solid Silicone Rubber |

| Mold | Compression mold | Injection mold | Dripping Injection Dispensing mold | Compression mold and Injection mold | Extrusion Mold |

| Molding process | Compression | Injection | Dispensing and compound | Over-molded | Extrusion |

| Mold Cavities | Single and multi-cavity | Single and multi-cavity | Single and multi-cavity | Single and multi-cavity | Single |

| Mold Life | Around 50000 | unlimited | unlimited | unlimited | Around 50000 |

| Colors | Single color | Single color | Multi-color | Colored or Single Color | Single color |

Advantages

Applications

Read More:

Custom Compression Molding Solutions For Your Business

At JUTION Silicone, we work with your timeline and budgets. Our cost-effective prototypes can be populated in small production runs that align with your schedule. We understand and meticulously implement the best tactics for achieving high-quality custom silicone baby products for your company.