Liquid Silicone Rubber (LSR) Injection Molding

What is LSR(Liquid Silicone Rubber) Injection Molding?

Liquid silicone rubber injection molding is the process used with liquid silicone rubber (LSR) to fix the material from an uncured state into a cured product.

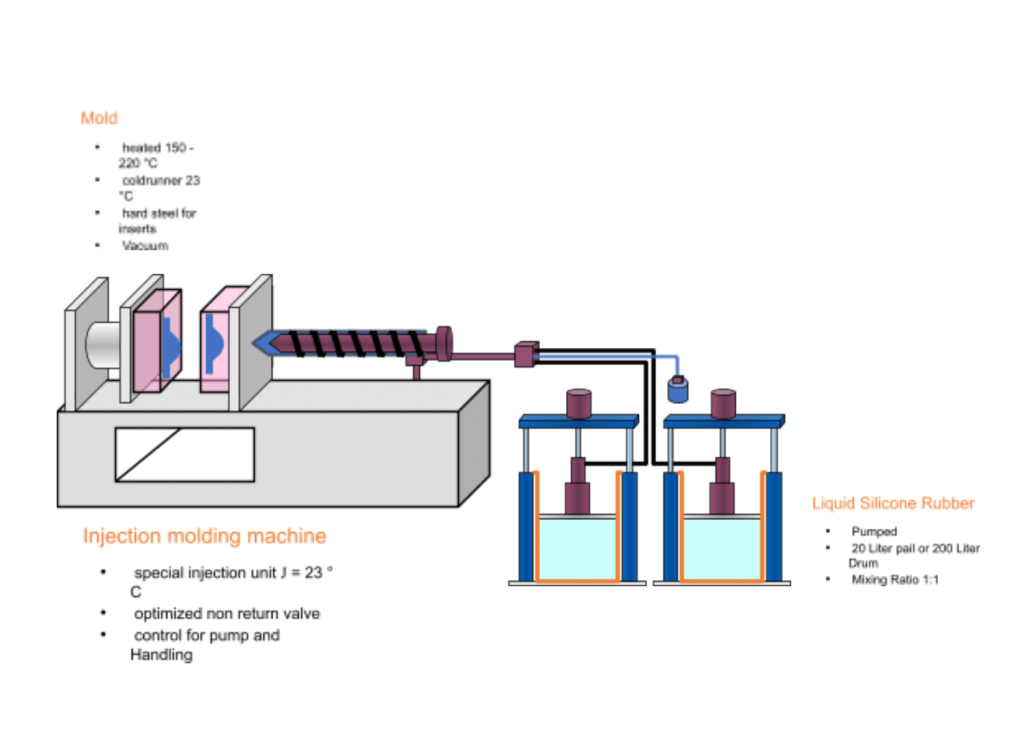

Liquid Silicone Rubber (LSR) can be processed in a liquid injection molding (LIM) process. The liquid raw material is mixed from two separate components in a ratio of 1:1 and injected via a cold-runner system into a hot mold. Curing takes place within seconds, offering the advantage of fast cycling and the production of large quantities.

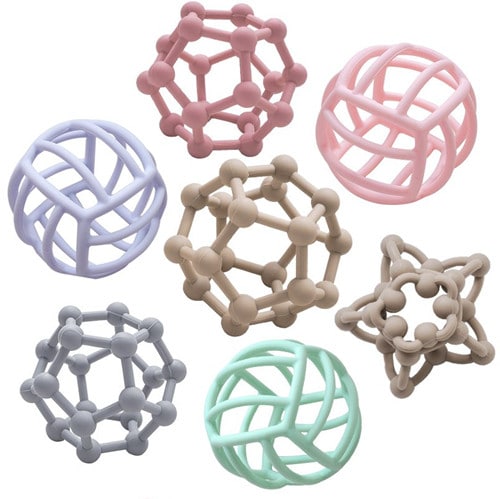

Injection molding of liquid silicone rubber (LSR) is a process to produce pliable, durable products in high volume (It is better at least 10000pcs/color). Then there will be have cost advantage.

LSR elastomer offers exceptional optical clarity, durability, and design flexibility while maintaining excellent mechanical properties across a wide range of temperatures (-50oC to 250oC).

Further Reading: The difference between injection molding and compression molding in terms of the definition, manufacturing process, materials used, production rates, costs, and applications.

Due to the flexibility in design and tooling, LSR injection molding is ideal for producing complex geometries and can consolidate various functional features into a single part. It also offers significant advantages in terms of product reliability and total cost of ownership.

Jution Silicone liquid silicone rubber (LSR) molding process produces custom prototypes and end-use production parts in 15 days or less. We use AL molds that offer cost-efficient tooling and accelerated manufacturing cycles, and stock various grades and durometers of LSR materials.

Quality Inspections and Finishing Options

Depending on your application’s requirements, you can choose from the following when requesting a quote for your silicone rubber products.

- Quality Inspections available for on-demand manufacturing orders

- Designing for Manufacturability (DFM) Feedback

- Scientific Molding Process Development Report

- In-process CMM inspection and machine monitoring

Get Custom Multi-colored silicone rubber baby products within days.

LSR machine introduction

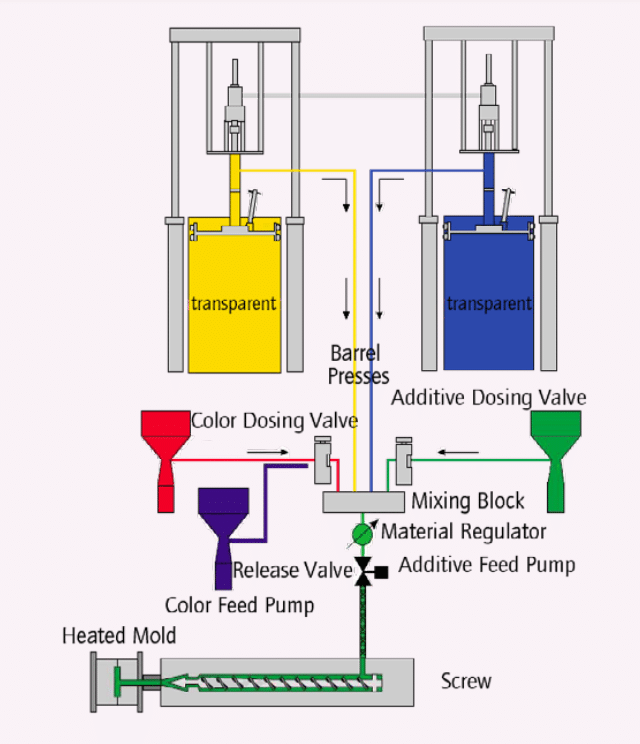

For the liquid injection molding process to fully occur, several mechanical components must be in place. Typically, a molding machine requires a metered pumping device in conjunction with an injection unit—a dynamic or static mixer is attached. An integrated system can aid in precision and process efficiency. The critical components of a liquid injection molding machine include:

An injecting device is responsible for pressurizing the liquid silicone to aid in the injection of the material into the pumping section of the machine. Pressure and injection rates can be adjusted at the operator’s discretion. This device transports the LSR-forming material into the pumping mechanism via pressurized force. The injection rate and pressure may both be modified by the machine operator. This variable fluctuates according to the project’s needs.

The metering device pumps the two liquid elements into a predefined ratio, ensuring that they are delivered at the same time and in the same proportion.

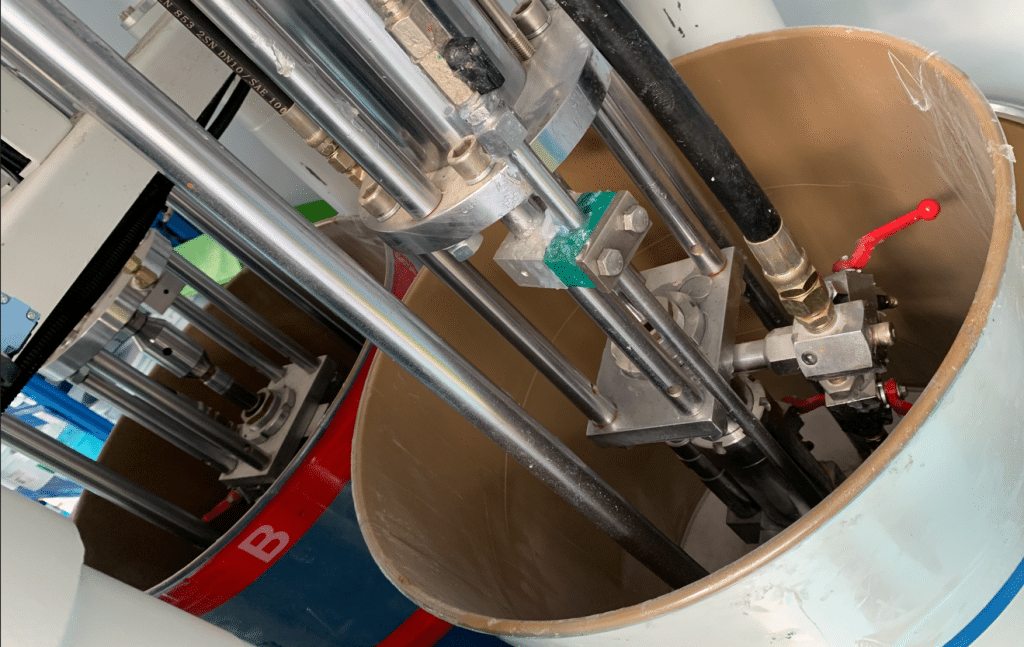

Supply drums, also called plungers, serve as the primary containers for mixing materials. Both the supply drums and a container of pigment connect to the main pumping system. The plungers are connected to the pumping system and are also known as liquid silicone supply containers. In two-container pigment setups, a third container is frequently incorporated

A static or dynamic mixer combines materials after they exit the metering units. Once combined, pressure is used to drive the mixture into a designated mold. The components are blended in a static mixer after the liquid-forming materials have gone through the metering device. Under pressure, the combined material is squeezed into the mold.

To facilitate the deposition of the mixture into the mold, a nozzle is used. Often, the nozzle features an automatic shut-off valve to help prevent leaking and overfilling the mold. The liquid compound is directed into the mold through a nozzle with an automatic shut-off valve. This valve prevents the mixture from seeping into the mold or overfilling it

A mold clamp secures the mold during the injection molding process and opens the mold upon completion.

The Liquid Silicone Rubber Injection Molding Process

Liquid silicon rubber material comes in a kit that consists of two components: “A” and “B”.

Step 1: The Raw Material

The uncured liquid silicone is contained in two containers, Compound A and Compound B, which connect to the pumping system. container A holds the base-forming material, and container B contains a catalyst. A metering unit automatically releases the two substances at a constant one-to-one ratio, as well as an additional color pigment for color parts.

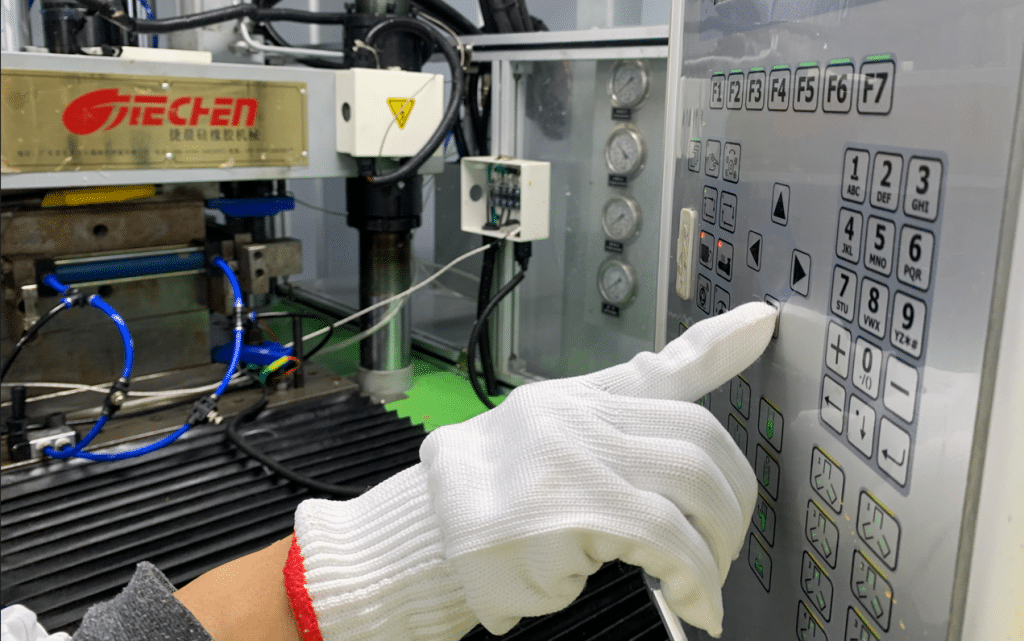

Step 2: Programs according to the products:

The molder programs and customizes the automated injection-molding machine to control the injection settings for delivery of the appropriate shot size for each job. The platens and pistons align and close the mold and have settings for the temperature, pressure, injection rate, and cycle time adjusted to meet the customer part designs.

Step 3: LSR – Injection molding:

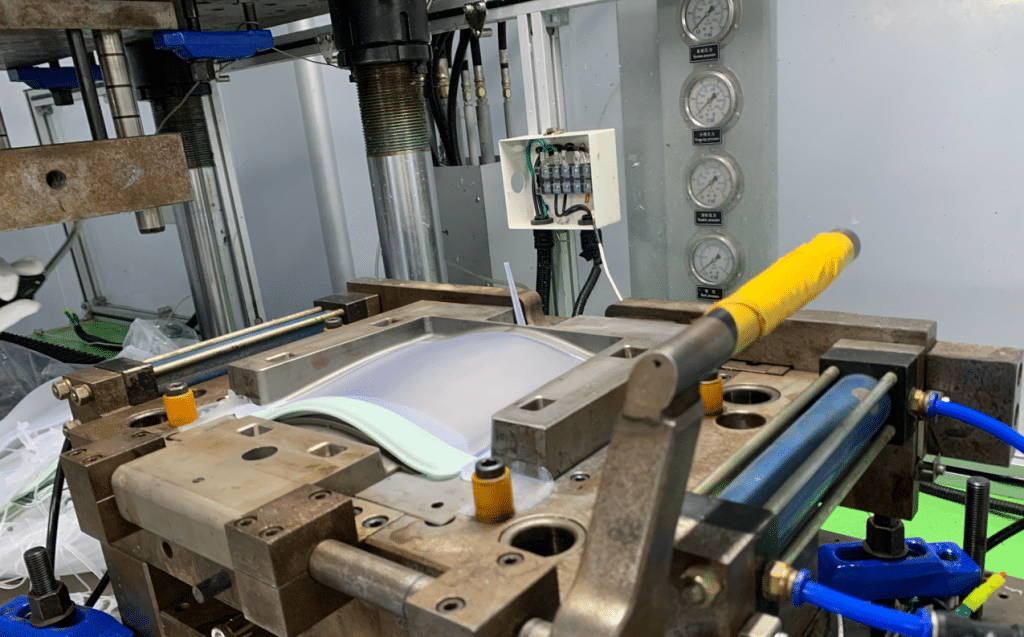

After the completion of the setup, the molding machine heats the mold’s cavities to the appropriate temperature and applies the appropriate clamping force. The mold closes in coordination with the machine’s injector, pump, and supply. The injection mechanism then pushes the material into the mold cavities. A combination of heat and pressure applied to the liquid silicone rubber cures the material until it solidifies.

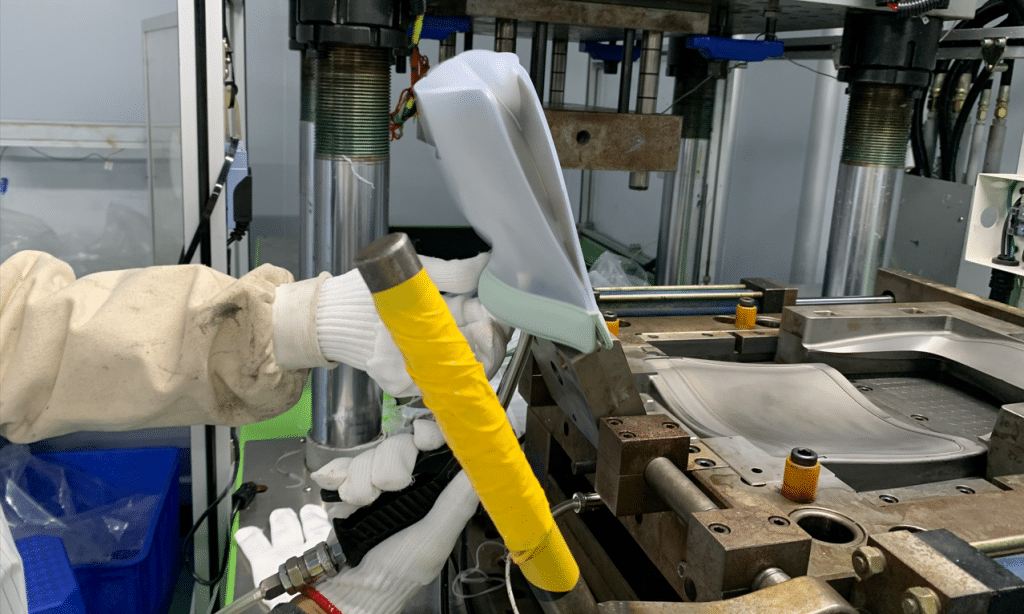

Step 4: Demolding – Deflash

Upon completion of the cycle, the mold opens for the demolding of the baby products. The baby products are removed and separated with an automated robotic parts removal system. In less sophisticated manual molding operations with smaller production runs, a worker removes the baby products.

After the demolding and product removal process, if post-molding secondary operations are required, these processes are performed after the molding is complete. Secondary operations could include slitting, printing, marking, assembly, or post-curing. Some advanced molders automate these steps and perform the value-added secondary processes immediately upon the removal of the products from the mold. The molded parts are robotically removed from the molding machines and delivered to a designated station for completion of the secondary process, within the same manufacturing cell.

Compare our Silicone Molding Manufacturing Services

| Silicone Rubber compression molding | Liquid Silicone Rubber (LSR) Injection Molding | Silicone Dripping Injection Dispensing(co-injection) Molding | Silicone Over-Molding | Silicone Extrusion Molding | |

| Material | Solid Silicone Rubber | Liquid Silicone Rubber | LSR and SSR | Silicone Rubber, Plastic, Metal | Solid Silicone Rubber |

| Mold | Compression mold | Injection mold | Dripping Injection Dispensing mold | Compression mold and Injection mold | Extrusion Mold |

| Molding process | Compression | Injection | Dispensing and compound | Overmolded | Extrusion |

| Mold Cavities | Single and multi-cavity | Single and multi-cavity | Single and multi-cavity | Single and multi-cavity | Single |

| Mold Life | Around 50000 | unlimited | unlimited | unlimited | Around 50000 |

| Colors | Single color | Single color | Multi-color | Colored or Single Color | Single color |

Advantage:

Application:

Read More:

Custom LSR Injection Molding Solutions For Your Business

Are you Searching for a new silicone baby products factory either to make a mold for your next product or a factory that provides a complete service (silicone mold + production and packing)? Jution Silicone is your choice.