Silicone Dripping Dispensing Molding

Dripping Injection Dispensing(co-injection) Molding is a process for making silicone multicolored products.

They allow two different silicone materials (solid silicone rubber and liquid silicone rubber) to be combined into a single product stream. Liquid silicone’s colors can be adjusted according to different customers, and the colors will do nothing to the qualities of liquid silicone. When in use, we need to mix the two parts evenly according to a certain proportion first, and then carry on the vacuum processing.

This specialized process can be used to enhance product color performance and reduce cost without any penalty to cycle time or production volume.

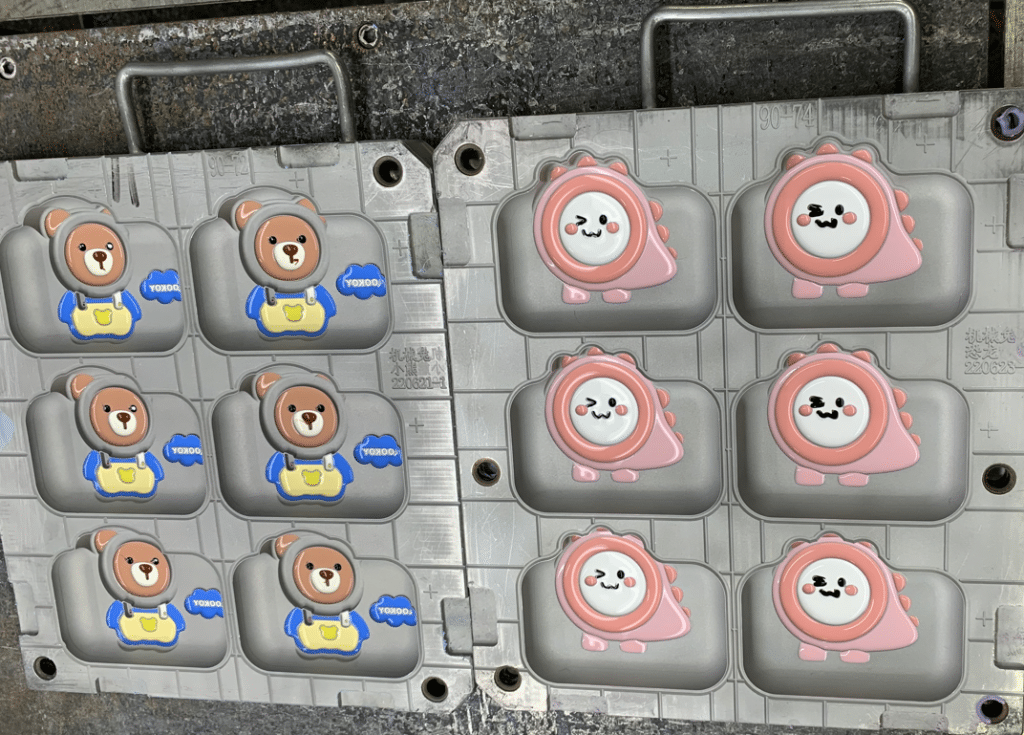

It is widely applied to the more multicolored silicone products. The colors and pattern can get from 2-12 colors and with a different pattern. It will be widely used for licensed products with characters. Especially for the games, IPs/Movies/Animation/ Character’s peripheral cute products.

Jution Silicone Dripping Dispensing Molding process produces custom prototypes and end-use production parts in 10 days or less. We use Copper molds that offer cost-efficient tooling and accelerated manufacturing cycles, and stock various grades and durometers of LSR and Solid silicone materials.

Get Custom Multi-colored silicone rubber baby products within days.

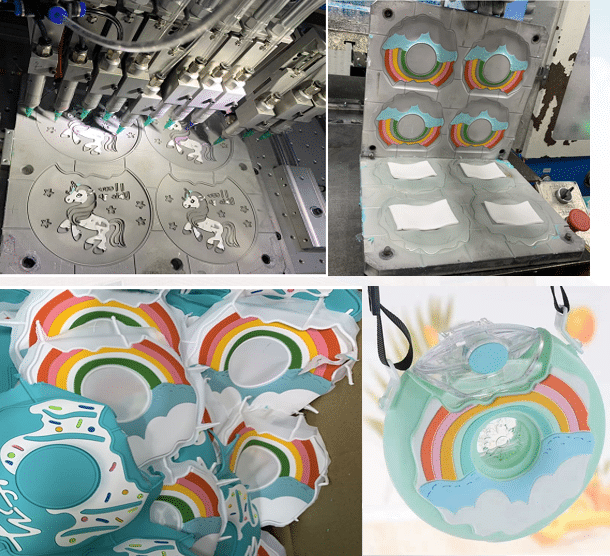

The Dripping Molding Process

This Processing is more complex, we often say the silicone trademark, silicone drip label, etc. Belongs to this kind of drip. Like drip teethers, dripping bibs, dining table mats, car interior decoration, and other series of products.

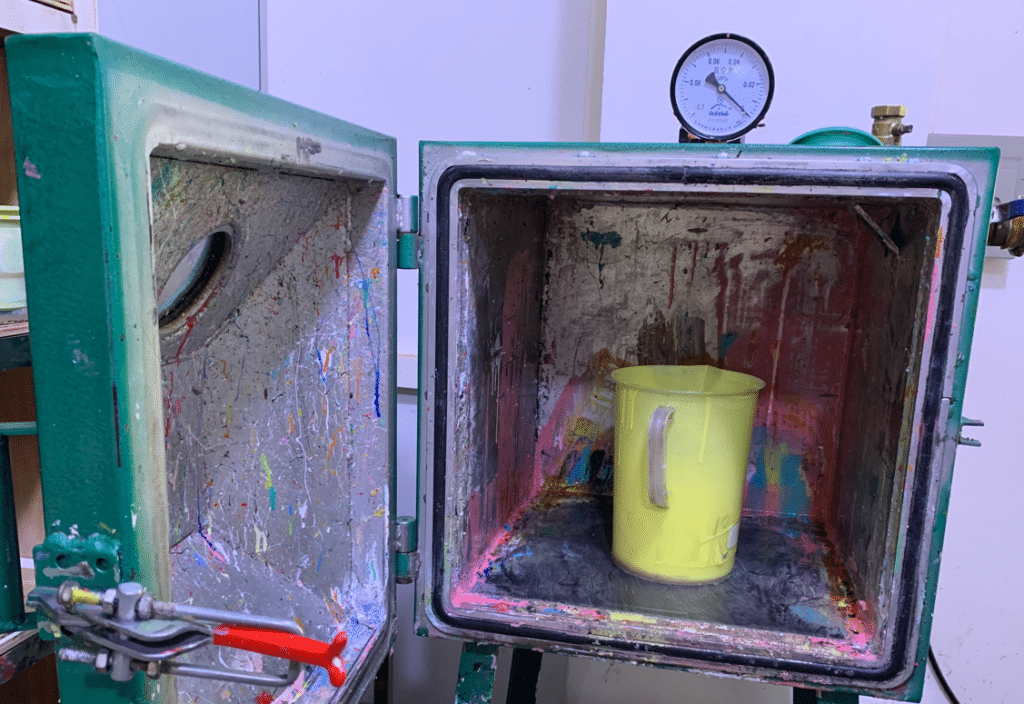

Air-exhaust by Vacuum

The Liquid Silicone Rubber material is Air-exhaust by Vacuum. Then add the pigment to get the colors that the colors needed.

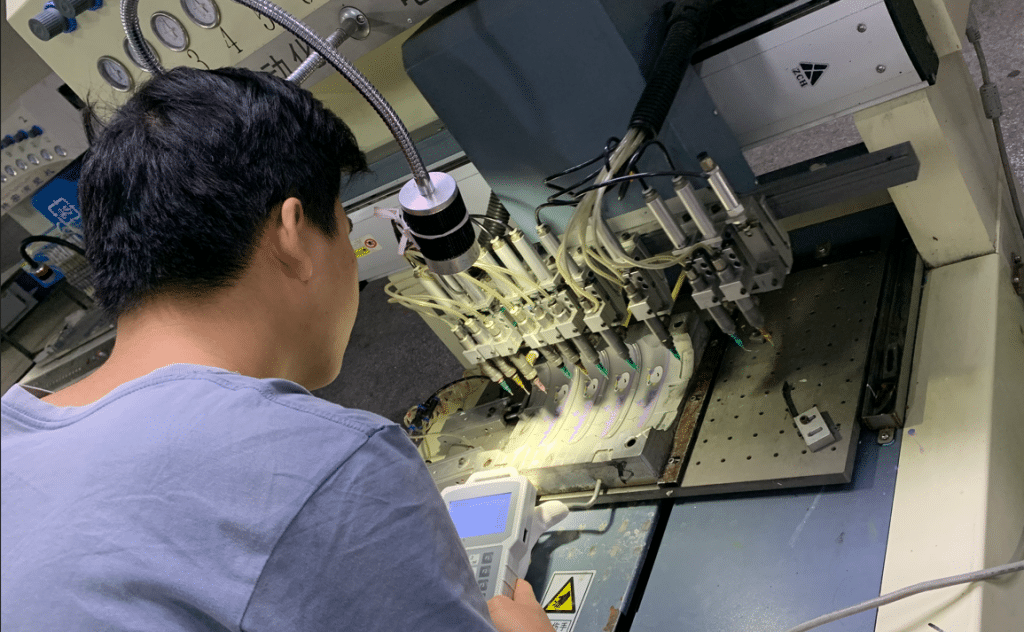

Program And Dripping The Liquid Silicone Rubber

The Precision Dripping molder programs control the dripping settings.

Twelve dripping heads can work 12 cavities same time and also can work 4 cavities with 3 different colors. One machine can save 4 to 6 workers. And Twelve fast buttons can run 12 different designs same time very easily and fast.

Heat-Cured

Heated the tooling and let the liquid silicone material is heated to solidify it.

Solid silicone material

Adding pigment to the silicone is performed by mixing via a two-mill roll.

Silicone raw material itself is a milk-white or transparent gum-like component with no elasticity and strength. To improve the characteristics of raw silicone material and to have the desired color, silicone material will be compounded with many ingredients such as vulcanizing agent, reinforcing filler, accelerator, colorant, etc.

Silicone compounding is the complex technology of selecting and blending silicone with other ingredients. The proper mixture is crucial to the success of silicone molding production.

Weigh it and shape it to match the needed size

It then will be cut into slices by an automatic cut machine. The slices’ length and width will be controlled according to the silicone part’s weight to be molded. Silicone blanking makes it easier for our molding operators to weigh the material during silicone molding production.

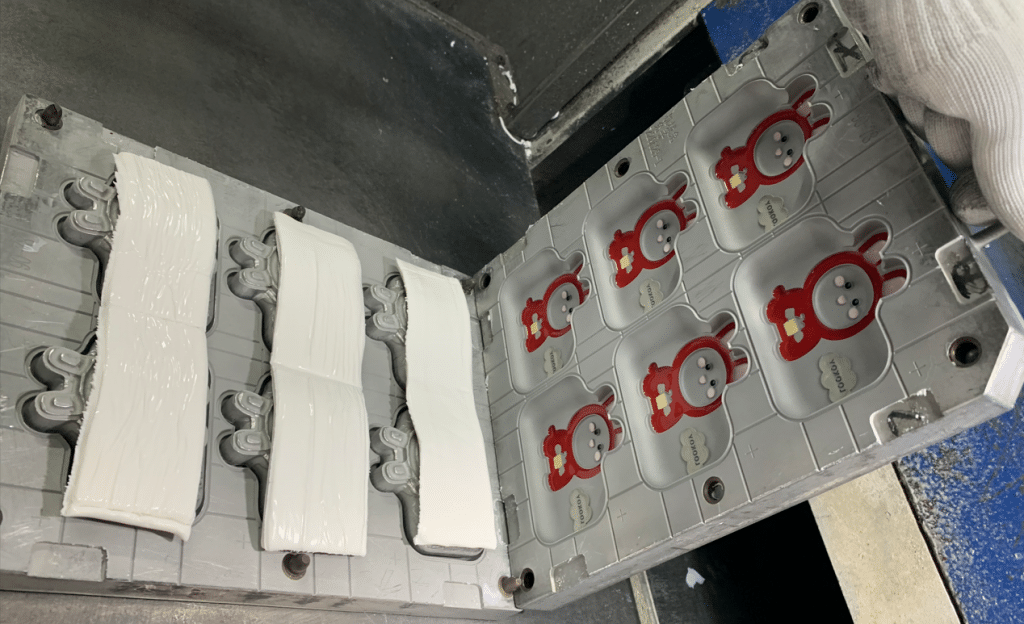

Co-injection Compression Molding

Put the Solid Silicone Material on the cured Liquid Silicone material on the tooling. Then They put it into the mold cavity for formation, compressing the silicone between the top and bottom plates.

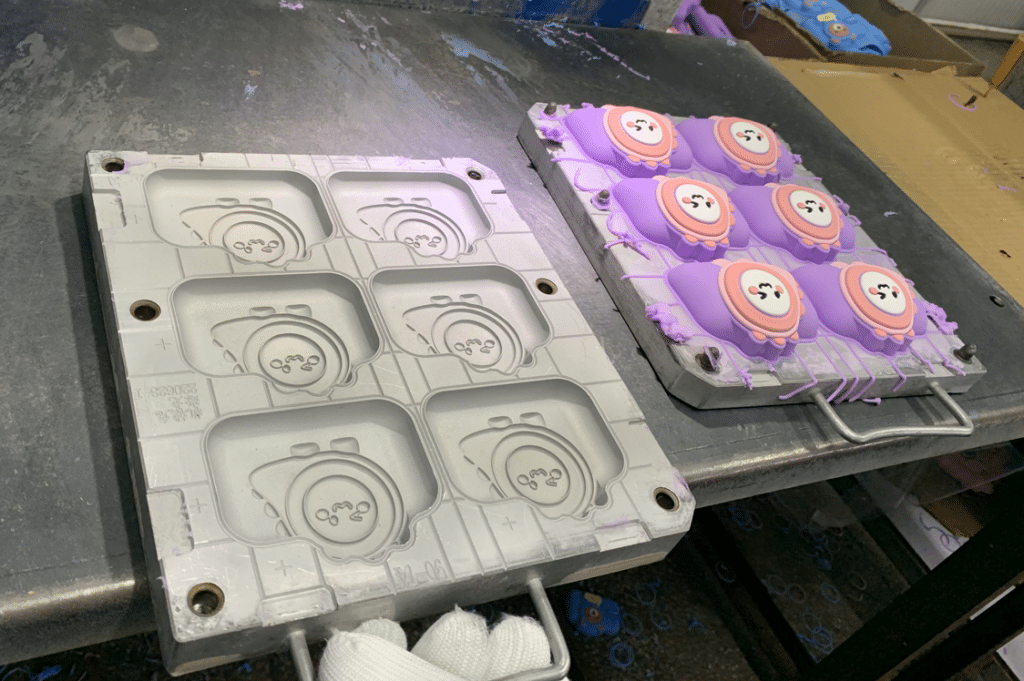

De-mold

When the silicone is fully cured, the vulcanizing molding machine will release the pressure automatically, tool mold will come out and open for molding operators to remove the molded silicone parts. The raw material will be placed again for the next round of vulcanization.

De-Flash

Flash can be minimized with favorable designs and better tooling and accurate material weight during vulcanizer molding production. Flash will be removed mainly by hand, cryogenics deflashing can also be applicated for some cases.

In Jution Silicone, we work with your timeline and budgets for your multicolored silicone baby products. Our cost-effective prototypes can be populated in small production runs that align with your schedule. We work closely for achieving high-quality custom colorful silicone products for your company. Get in touch to learn more and order your custom multicolored silicone baby products.

Compare our Silicone Molding Manufacturing Services

| Silicone Rubber compression molding | Liquid Silicone Rubber (LSR) Injection Molding | Silicone Dripping Injection Dispensing(co-injection) Molding | Silicone Over-Molding | Silicone Extrusion Molding | |

| Material | Solid Silicone Rubber | Liquid Silicone Rubber | LSR and SSR | Silicone Rubber, Plastic, Metal | Solid Silicone Rubber |

| Mold | Compression mold | Injection mold | Dripping Injection Dispensing mold | Compression mold and Injection mold | Extrusion Mold |

| Molding process | Compression | Injection | Dispensing and compound | Overmolded | Extrusion |

| Mold Cavities | Single and multi-cavity | Single and multi-cavity | Single and multi-cavity | Single and multi-cavity | Single |

| Mold Life | Around 50000 | unlimited | unlimited | unlimited | Around 50000 |

| Colors | Single color | Single color | Multi-color | Colored or Single Color | Single color |