Custom silicone products for your business

Jution silicone offers high-quality 100% food grade custom silicone products suitable for baby products/homeware brands, baby and homeware products wholesale/ retail store. Whether you’re a customer in any of industries, Jution silicone can produce silicone products to meet your needs for empowering your brands.

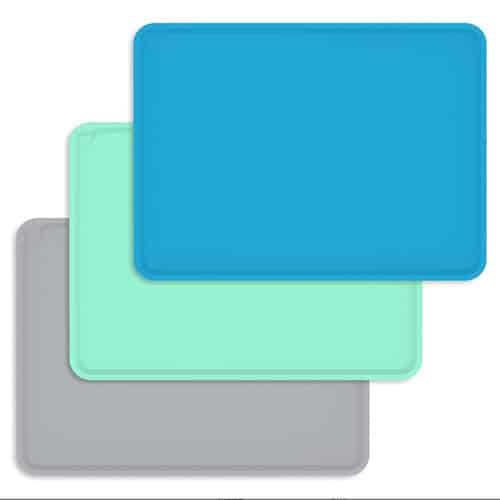

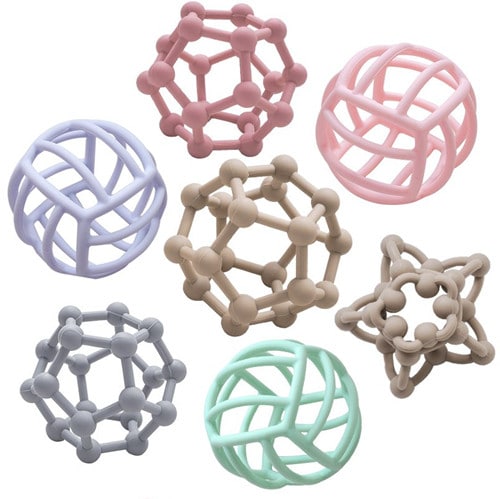

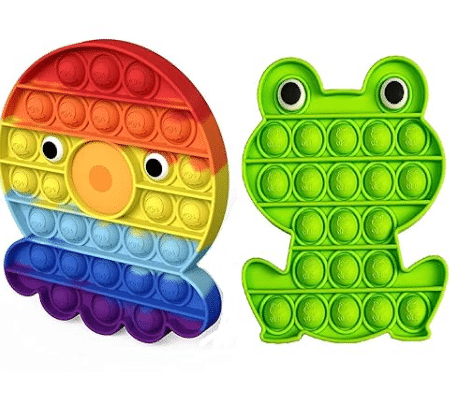

We pride ourselves on being a leading manufacturer specializing in the design, development, and production of custom silicone baby products. With a focus on quality and innovation, we have been serving the market for over 16 years, providing a wide range of silicone baby products such as:

Enterprise and Organization Customization Service

Efficient and professional silicone baby products solutions, realize all your ideas.

At Jution silicone, you will get the most cost-effective custom baby products brands solutions. We can help you design your baby products with your idea. We also can help you achieve mass production soon if you already have CAD or STP drawings.

Custom branding logo and packaging

Logo types mainly have: Laser logo, Debossed or Embossed logo, screen printing and Heat transforming printing logos. Customized packaging solutions for manufactured custom baby silicone products. Our custom packaging includes paper boxes, PE/PVC boxes, hangtags, barcode stickers, etc.

About Jution Silicone

Jution Silicone is a silicone baby products OEM /ODM expert more than 15 years. We support your silicone baby products brand to be the baby and parents preferred brand.

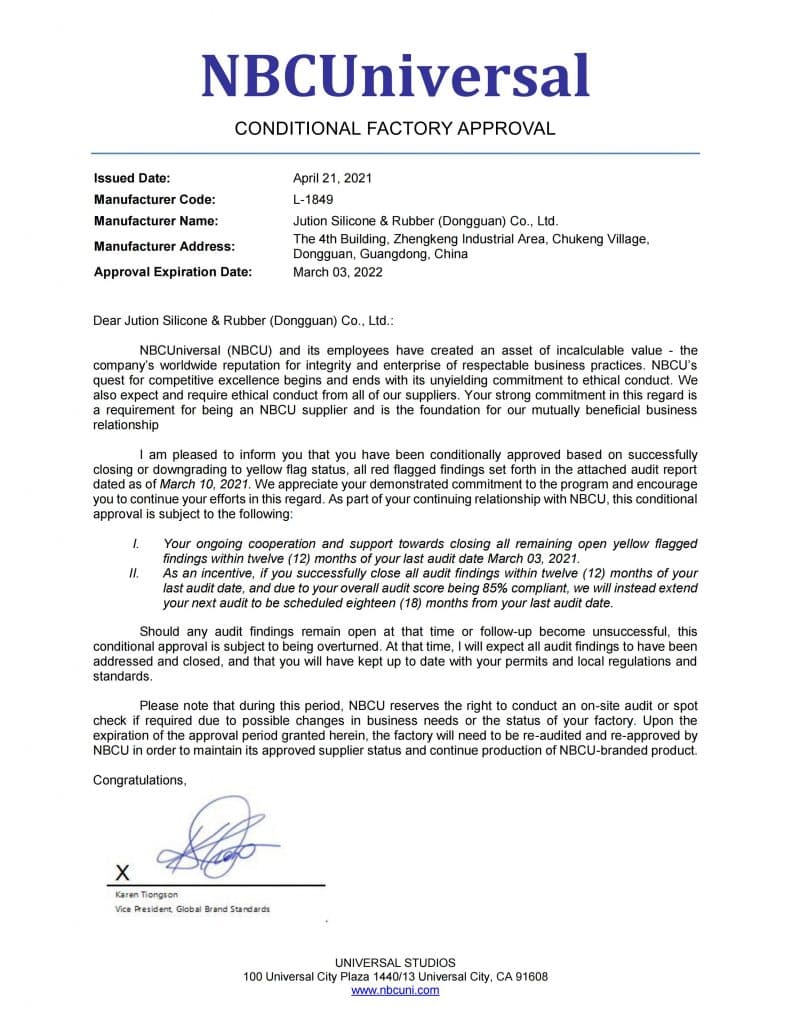

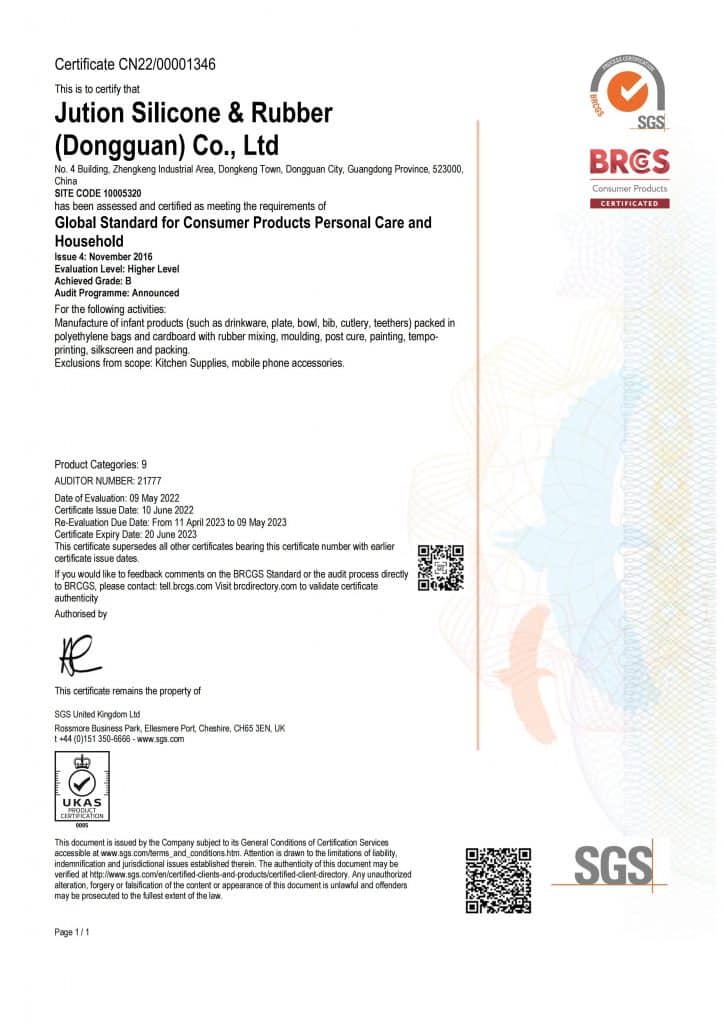

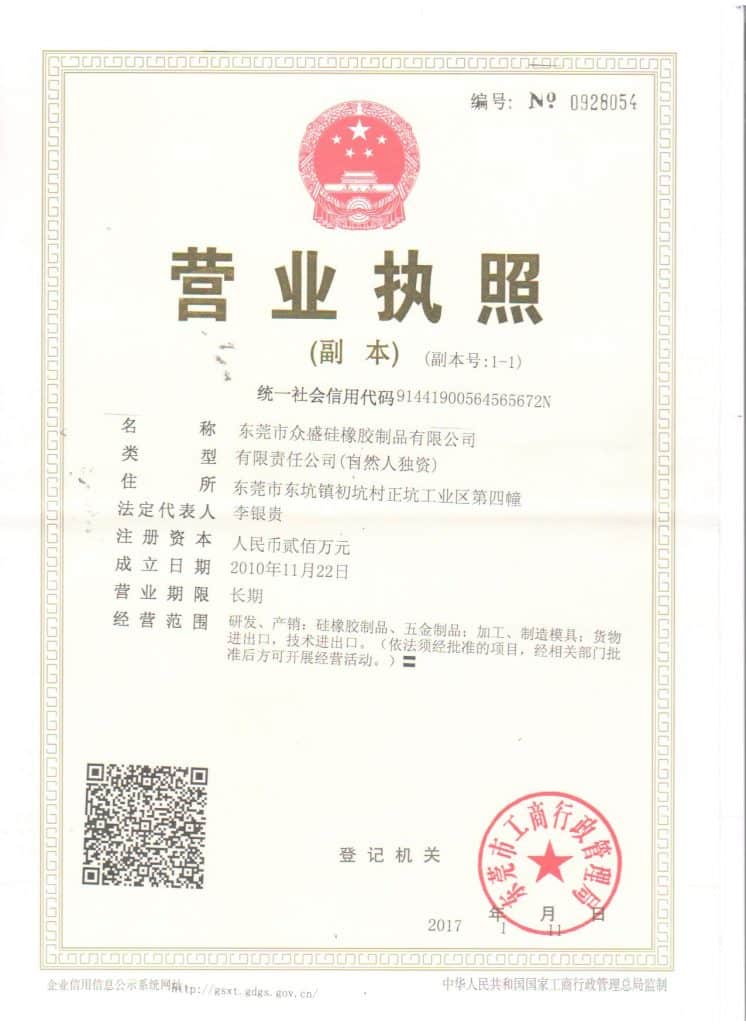

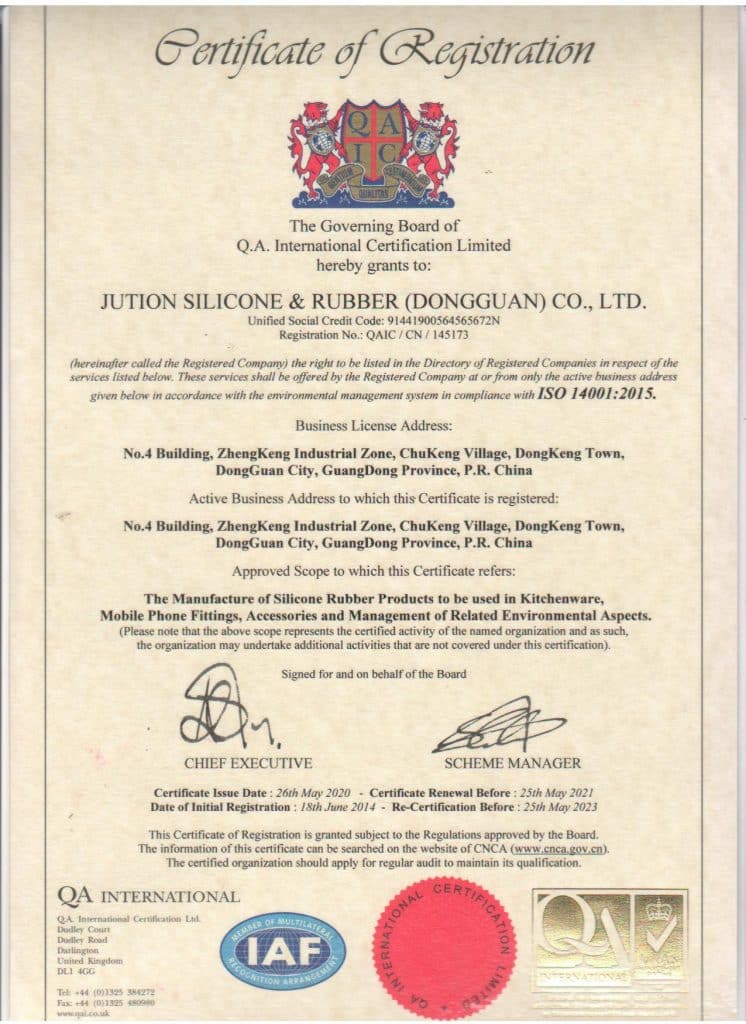

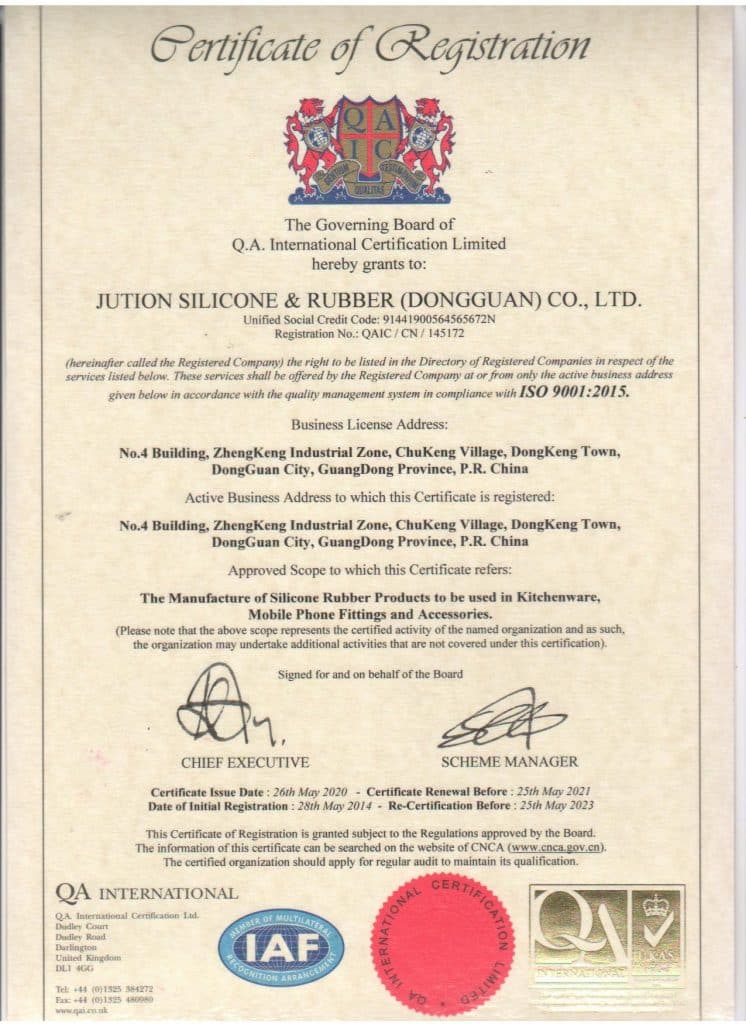

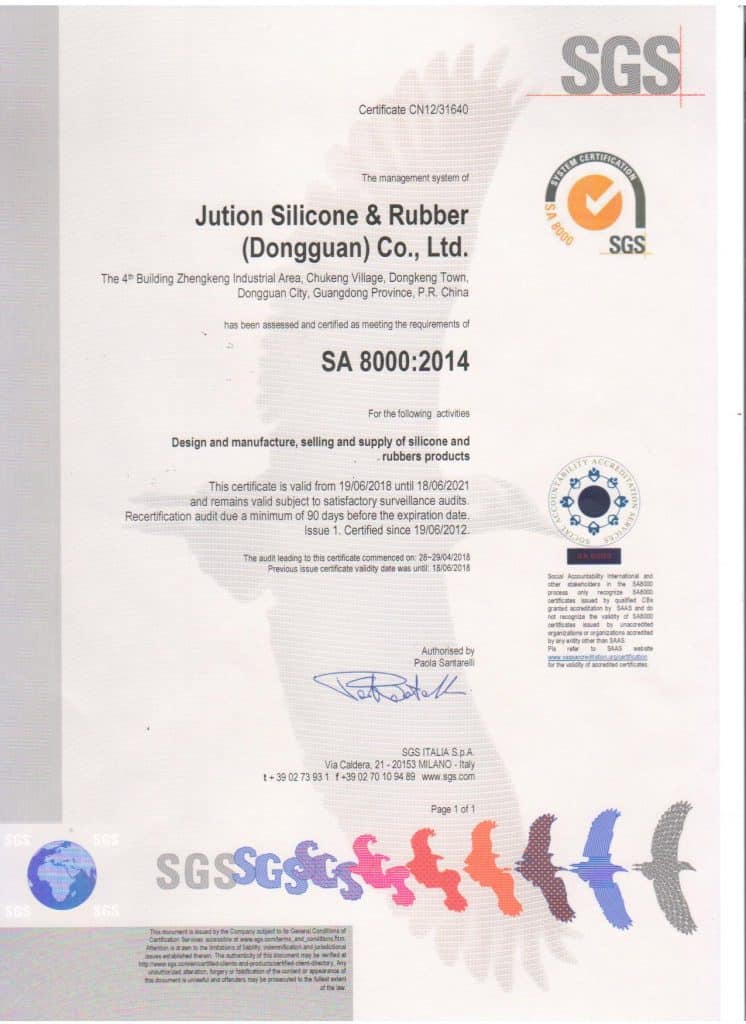

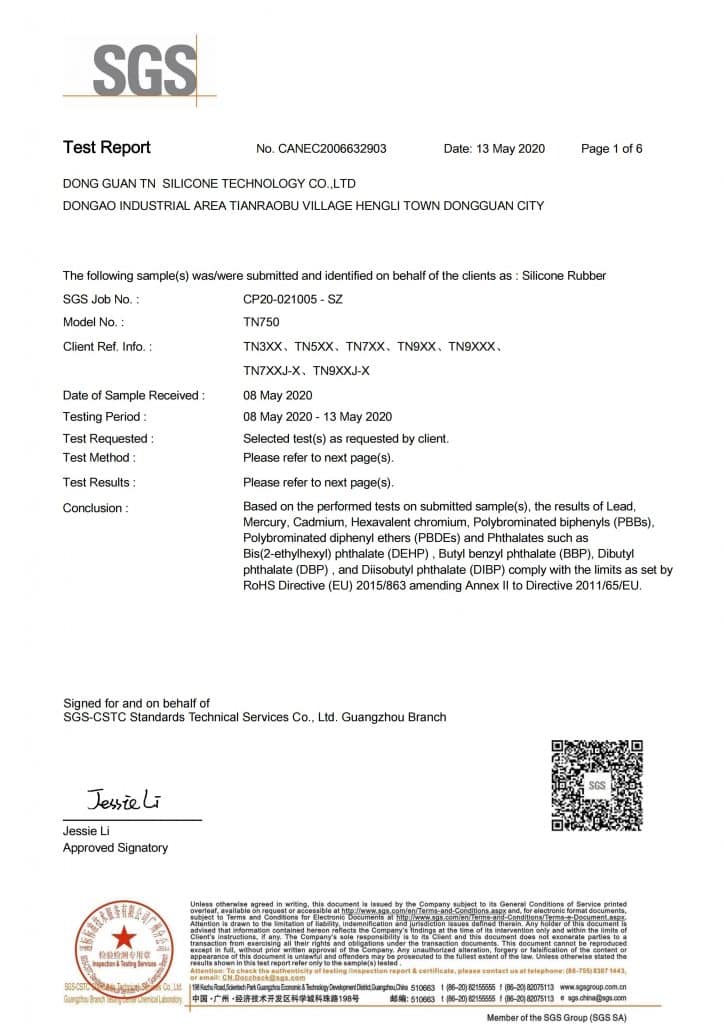

Jution Silicone & Rubber (Dongguan) Co., LTD is certified by SA8000, ISO9001, ISO14001, BSCI, SEDEX, BRC, FCCA, NBCU, and Disney.

We have experience working with a diverse range of clients, including baby or homeware brands, Retail chain store, Marketing advertising companies, supply chain management companies, product development companies. Whether you’re looking to commission any logoed silicone baby products. Jution silicone has the expertise and experience to bring your vision to life.

Bing Dwen Dwen–That is our great honor we are the only licensed manufacturer of the Beijing 2022 Winter Olympics 25cm Mascot shell partner.

We welcome any bespoke silicone baby products you need development, or silicone baby products technical inquiries from you.

They trust us

World-Class Solutions, Globally Recognized

Cooperated with worldwide famous brands in baby’s products industry, you can find them in Walmart, ALDI and buy buy BABY supermarkets. Jution siicone is a reliable babies silicone products manufacturer behind some well-known brands. Jution silicone is pioneering Custom Silicone Baby Products for Over 16 Years.

Our dedication to excellence is evident through our numerous certifications, including SA8000, ISO9001, ISO14001, BSCI, SEDEX, NBCU, and Disney. These accreditations not only affirm our commitment to quality and ethical standards but also showcase our efforts in maintaining a sustainable and environmentally friendly manufacturing process.

Jution siilcone is not just a supplier; we’re your trusted ally in innovation, dedicated to delivering excellence with every silicone baby product.

To Create Silicone Baby Products,

There is a Need to Collaborate with Real Experts

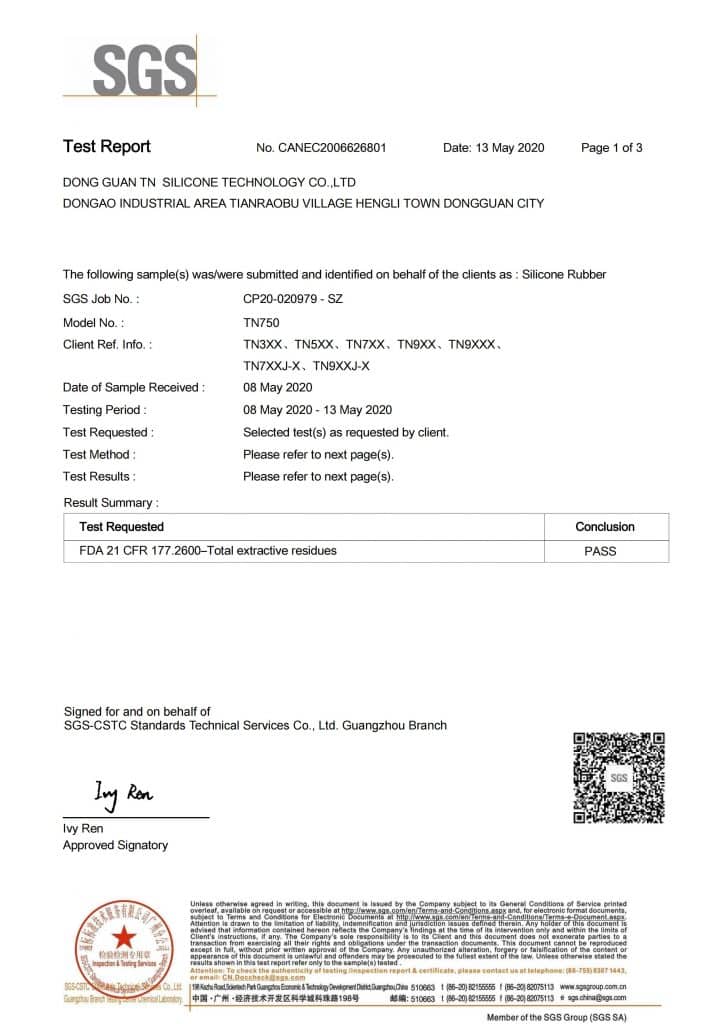

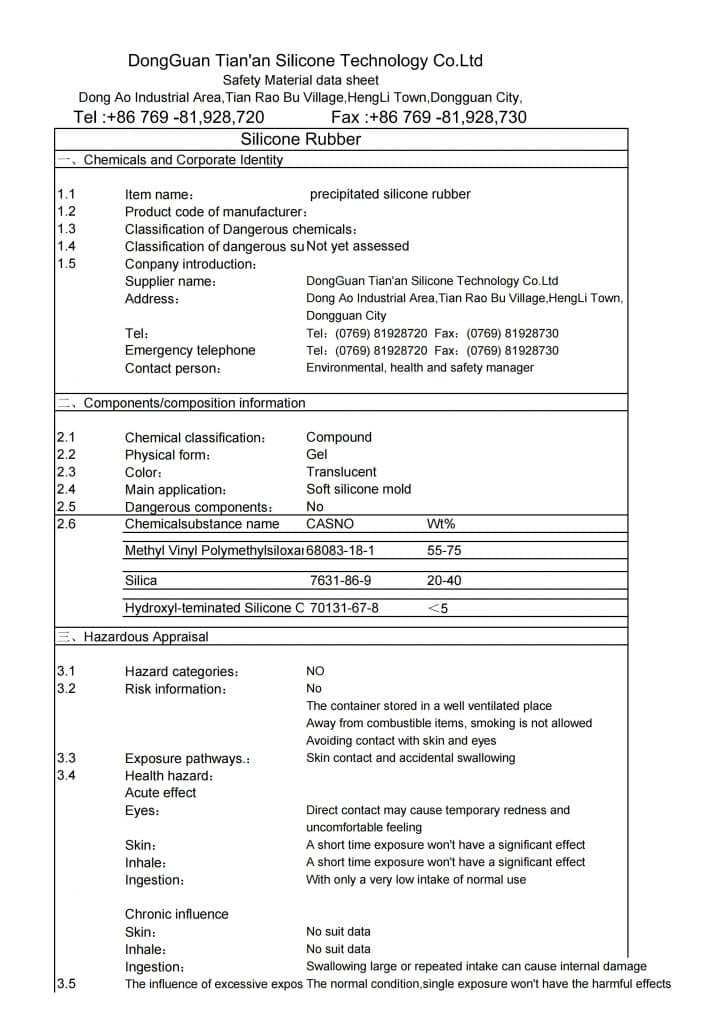

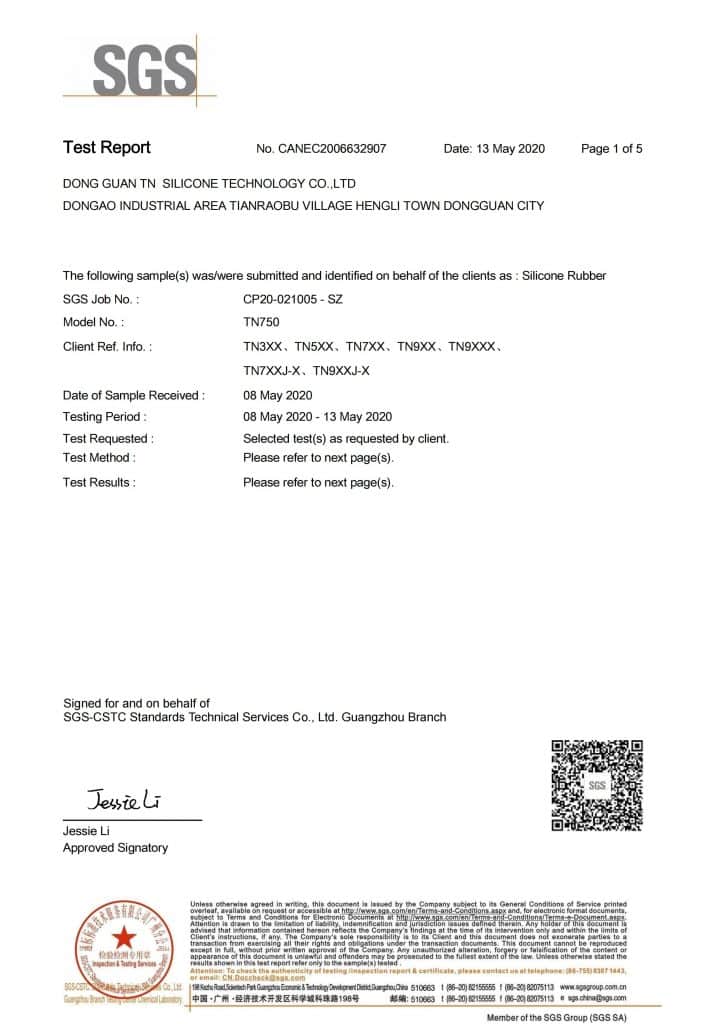

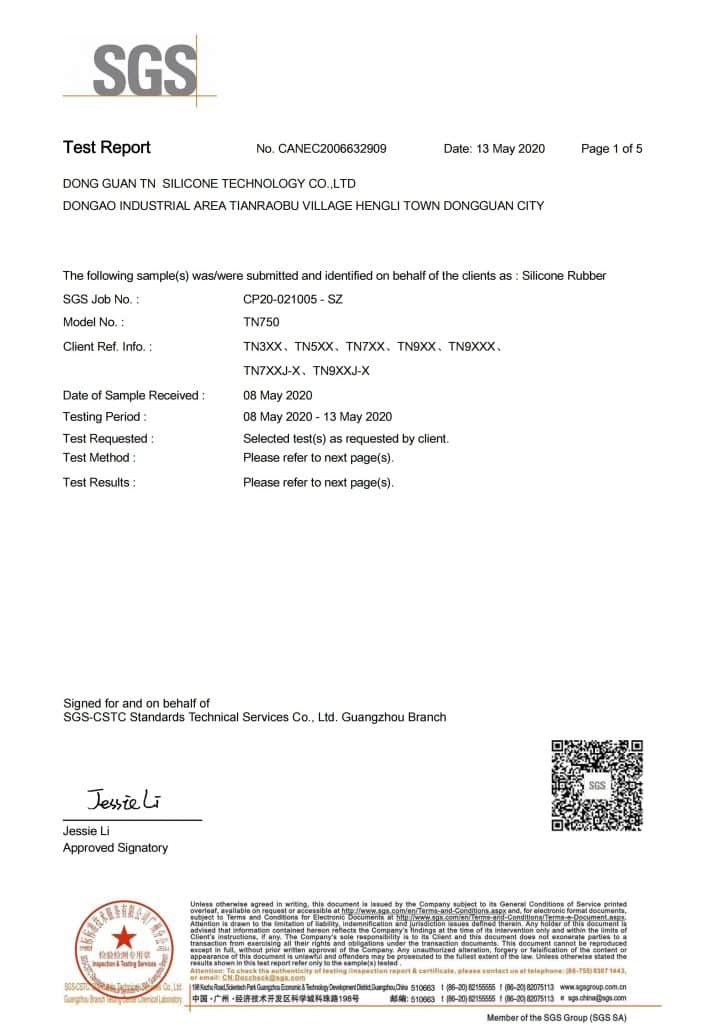

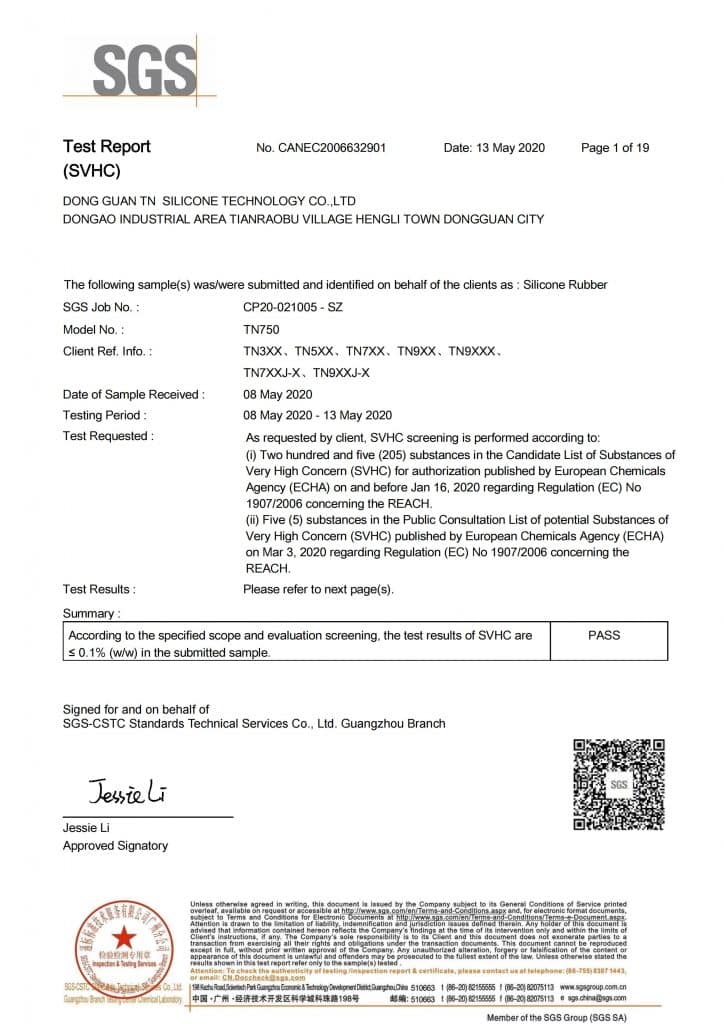

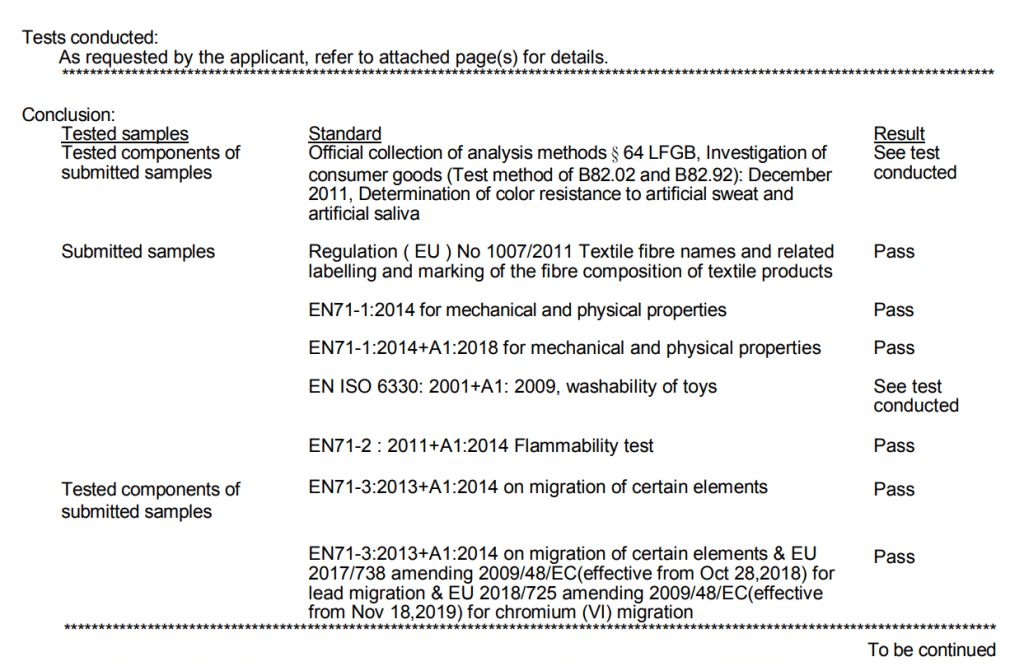

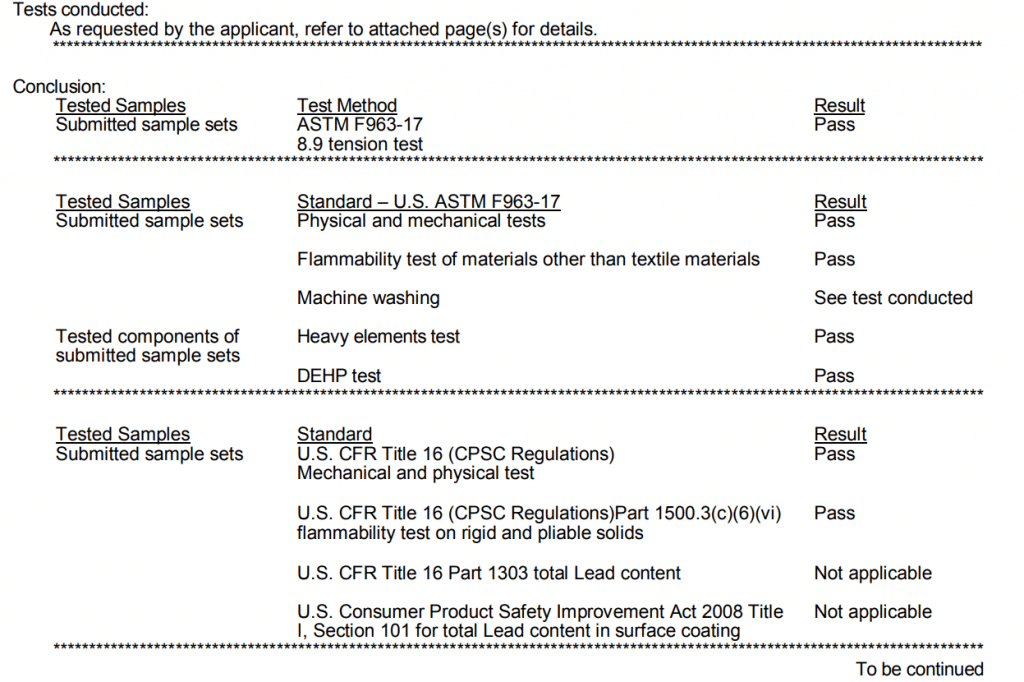

All the silicone baby Feeding, Toy, Care, and Accessories products in Jution Silicon are made of food-grade high-quality silicone materials, 100% high-purity food-grade silicone, which are safe and environmentally friendly, non-toxic and harmless, giving babies a sense of security, and giving mothers a sense of peace of mind. All the materials that we used have the certification: FDA, LFGB, and ROSH. REACH, PAHS, Phthalate report etc if needed.

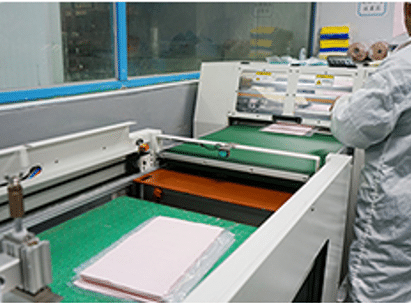

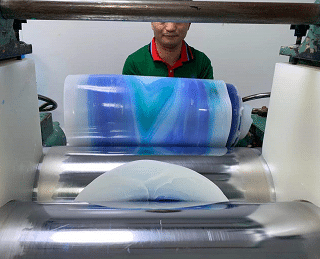

12+ designers and engineers,21 sets of advanced CNC ,10 sets of EDM spark machines for making the silicone baby products tooling.The inhouse silicone mold-making shop can support flexible prototype modification. All the silicone baby products manufacturing from silicone baby bibs development cycle under one roof- from designing products & building tooling to launching into full-blown production. You will reduce the risks of working with multiple vendors, save your time to market ,lower costs and shorten the development cycle.

Jution have the own Secondary Vulcanization workshop, Laser engraving workshop, pad printing, screen printing, painting workshop, package workshop all the silicone baby products manufacturing from silicone baby bibs development cycle under one roof- from designing products & building tooling to launching into full-blown production to the market. You will get a quickly run-up for your silicone baby project and save your time to market & lower costs.

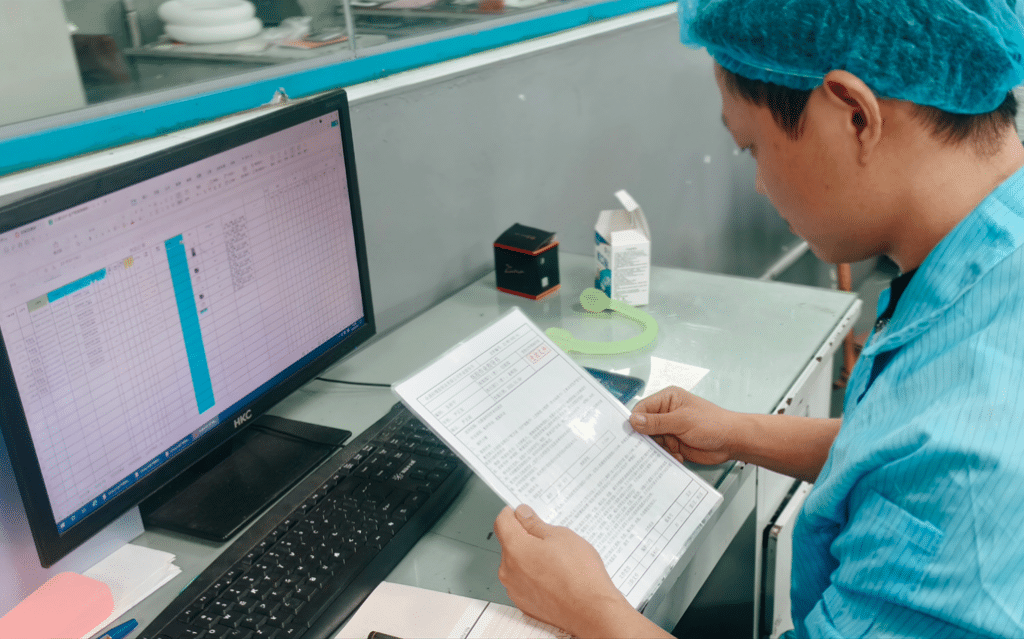

Jution Silicone&Rubber (Dongguan) Co., LTD the whole-process quality control system from silicone baby products developments to finished products ensures that our customers can receive the qualified Silicone baby products as the prototype they approved before mass production.

All silicone baby products have a date code added to them from the time they are molded, and they have an irremovable tracking code from the time they are ordered. All your silicone project to be taken seriously, and we can make you satisfied. We optimize our production processes based on our experience. You can keep track of the project and ask for anything you need at any time.

NDAs are one of the most fundamental tools we use to protect your interests. Signing an NDA means that your ideas and designs will be protected by law. No more concerns about leaks

Let every baby in the world use safe and eco-friendly silicone products

The safety of silicone baby products is our top priority for us.We believe that all mothers hope to use high-quality baby products for their babies.

People Also Asked:

Still Have Questions?

If you cannot find an answer to your question in our FAQ, you can always contact us and we will be with you shortly.