How do I know if my silicone products are 100% LFGB silicone?

What is LFGB Silicone?

LFGB Silicone is a premium grade of silicone that has passed LFGB testing standards.

LFGB is standard mainly for Europe, Silicone products sold in Europe except for Germany & France must meet the European Food Contact Regulations – 1935/2004/EC. Silicone products sold in Germany & France must meet ‘LFGB’ testing regulations which is the toughest of all standards – this type of silicone material must pass more intensive testing, is of a better quality and is therefore more expensive. It is also known as ‘Platinum Silicone’.

“The LFBG (Lebensmittel-, Bedarfsgegenstände-und Futtermittelgesetzbuch, or “Foods, Consumer Goods and Feedstuffs Code”) is sometimes thought to be the European equivalent of the FDA. This is not quite correct. The LFGB is the German enactment of European law as operated by the Bundesinstitut für Risikobewertung (BfR). The BfR recommendations for food-contact materials are some of the more comprehensive in the EU”.

Silicone products that pass either one of these tests are deemed safe for human use.In terms of pricing, products in LFGB standard will be more expensive than FDA standard, so FDA is more widely used. This is because LFGB method of testing is more comprehensive and strict.

The difference between LFGB and FDA lies in the different methods of testing, with LFGB testing regulations the toughest of all standards where the silicone material must pass more intensive testing compared to FDA silicone testing.

Even though both FDA & LFGB approved silicone are considered food safe, silicone that has passed LFGB testing is a higher quality silicone.

All FDA Products Are Not Equal

There are two testing standards for Silicone that can be sold that are considered food grade.

Different countries have different standards that silicone products must meet to be deemed safe for human use when in contact with food.

In the US & Australia, the minimum standard for silicone products is ‘FDA’ testing (Food & Drug Administration standard).while FDA (Food and Drug Administration) is the base level standard in the USA and Australia. Most countries have their own FDA standard, but the USA FDA is the most internationally applied.

LFGB is standard mainly for Europe, Silicone products sold in Europe except for Germany & France must meet the European Food Contact Regulations – 1935/2004/EC. Silicone products sold in Germany & France must meet ‘LFGB’ testing regulations which is the toughest of all standards – this type of silicone material must pass more intensive testing, is of a better quality and is therefore more expensive.

How do I know if my silicone product is 100% LFGB silicone ?

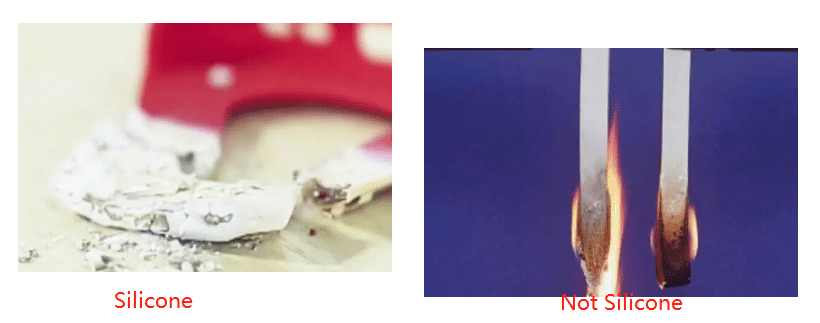

1. Burn it.

Becuase When you Pinch or pull test the PVC, it will not trun white. So, before you make the Pinch test, you need burn it first to see if the products are made of silicone.

Silicone products are generally transparent, with small burning smell and White powder.

PVC products will turn black after burning and smell bad when burning.

When you confirm it is made in silicone. then do the next step:

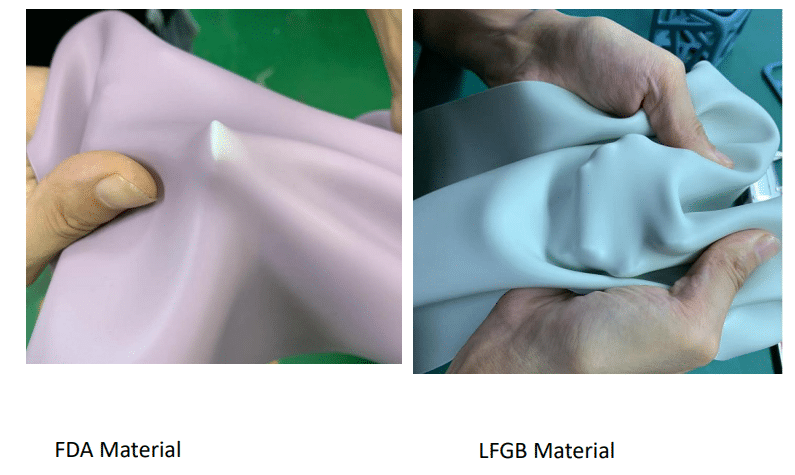

2. Pinch or pull test.

Whenever you buy a silicone product you can easily test to see if it contains fillers using the pinch or twist test. Its as easy as it sounds – pinch or twist the silicone – if it changes to a whiteish color, then it most likely it is not 100% LFGB silicone.

Pinch, stretch, and twist the silicone – if it turns white it is not 100% LFGB silicone. Our products will pass the pinch test because they contain only 100% pure silicone. LFGB silicone is much more costly than FDA because LFGB doesn’t allow ANY fillers.

The Pinch Test: an easy way to test for fillers in silicone. Pinch, twist, or pull silicone. If it turns white, it has fillers.100% Silicone LFGB products will ALWAYS pass The Pinch Test because they are made with 100% Pure silicone with no fillers.

Don’t be fooled by other brands’ claims that they are 100% silicone without fillers. Many brands claim to be 100% silicone because they have passed an FDA food safe test, but this test does not determine if there are fillers in the silicone.

A key item to note in these standards is that Silicone products are allowed to have impurities or fillers as long as they stay beneath the “safe” levels. Simply put, “food-safe” silicone can still have fillers in it.

Many brands use FDA Silicone in their silicone products because they are cheaper than LFGB silicone. They can do this as long as they can stay within the bounds of the FDA testing requirements. FDA tests are less strict than European testing (such as LFGB). This practice occurs with both US manufacturers and overseas manufacturers.

Many brands also claim that they pass the pitch test, but they do not. Thicker silicone items, like cups and plates, need more force to see the fillers whereas a thinner product, like a silicone bib or mat, can be lightly stretched to see the impurities. 100% pure pure silicone should never change color when you twist, pinch or pull it.

Further Reading:

-

What you need to know about silicone allergy

-

TPU(Thermoplastic Polyurethane)and Silicone

-

The Silicone Toys for Kids and Adult -Pop-it

-

The safety and cleaning methods of silicone baby toys

-

The diversity of silicone toys Stimulating babies’ desire for exploration

-

The difference between silicone and rubber

Conclusion

Even though both FDA & LFGB approved silicone is considered food safe, silicone that has passed LFGB testing is definitely a better quality silicone resulting in greater durability and less foul silicone odour and taste.

Manufacturers will use different quality silicone material depending on their customer’s requirements i.e. whether they require FDA or LFGB approved silicone – which will depend on where the customer plans to sell their silicone products and also to what level of quality they want to offer their customers.

Jution silicone rubber deeply about the health of our customers, so we ensure our silicone baby products are produced to the highest quality using LFGB certified silicone when you confirm to us that is your needs.

Related Blog

-

The Silicone Toys for Kids and Adult -Pop-it

The Silicone Toys for Kids and Adult -Pop-it What is Pop-It silicone toy? Pop-It is a molded silicone toy that mimics the feeling of squeezing and has become a popular toy in elementary schools across the United States in recent years. The toy’s simple design allows users to experience the sensation of bouncing back by

-

The safety and cleaning methods of silicone baby toys

The safety and cleaning methods of silicone baby toys As a professional who has been deeply involved in the field of silicone materials for many years, I am well aware of the importance of safety and cleanliness of infant and toddler products. Due to its unique diversity, silicone baby toys have become an ideal choice

-

The baby’s first water cup Recommended

The baby’s first water cup Recommended Over the years, I have witnessed how silicone materials have reshaped the landscape of maternal and infant products with their unparalleled safety and functionality. The “first water cup” is an important tool for babies to transition from breast milk or bottles to independent drinking. At this time, our top

-

Silicone vs. Plastic Why are silicone baby products more recommended

Silicone vs. Plastic Why are silicone baby products more recommended As a professional with many years of experience in the silicone material field, I’ve witnessed how silicone, with its unparalleled safety and functionality, has reshaped the landscape of maternal and infant products. In this age of information overload, the sheer variety of baby products available

-

Silicone bowls vs. plastic bowls Which one is the best choice for babies

Silicone bowls vs. plastic bowls Which one is the best choice for babies As a professional who has been deeply engaged in the field of silicone materials for many years, I have witnessed how silicone materials have reshaped the landscape of maternal and infant products with their unparalleled safety and functionality. As a person with