Injection molding VS Compression Molding

Here we show the difference between Injection molding and compression Molding in terms of the Definition, manufacturing process, materials used, production rates, cost, and application. Please go through this to learn more about these two processes.

In Jution Silicone & Rubber Co., LTD, We offer the injection molding service and the compression molding service according to the customer’s different silicone products. Choice of the best-fit silicone molding process for our clients.

The Definition: Injection molding and Compression Molding

What is Injection molding?

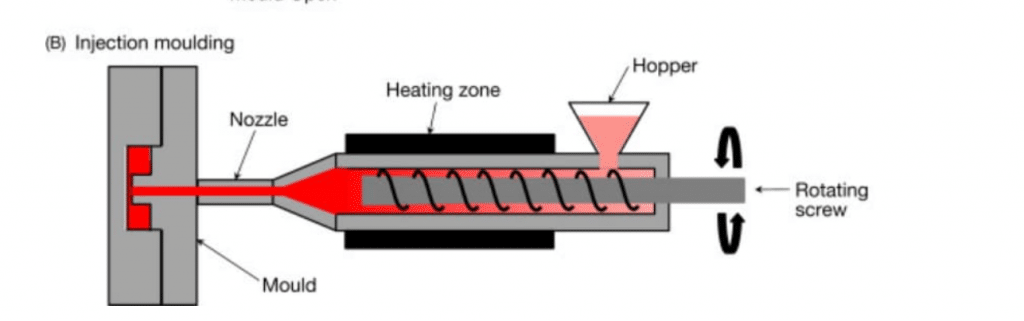

Injection molding is a molding process that’s defined by its use of injection technology. It’s called “injection molding” because it involves the injection of raw material into a mold cavity. During injection molding, a screw pulls the material into a hopper. The heating process follows, and then injection into the mold cavity. The heated material cools and sets in the shape of the mold cavity.

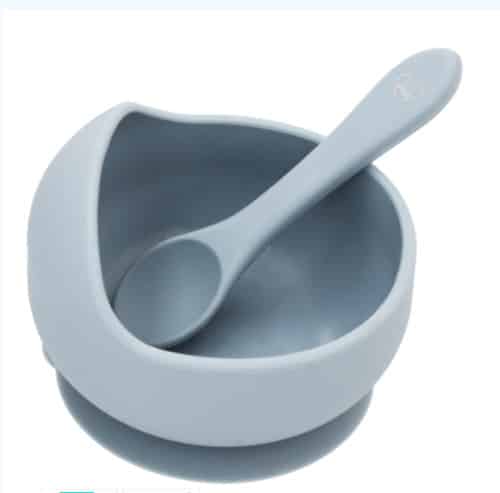

Injection molding is a manufacturing process used for the mass production of identical plastic parts and liquid silicone rubber. It’s a method of silicone injection where Liquid Silicone Rubber is inserted into a mold to produce a part in the shape of the mold cavity, creating a physical representation of molded silicone products.

This method offers many benefits in terms of production.

- High Production Efficiency: Suitable for large production runs, enabling the rapid production of large quantities of products.

- Cost-Effectiveness: Offers low per-part cost at scale, particularly effective for producing thousands to hundreds of thousands of parts. sometimes it costs just cents per part for parts at scale

- Consistency and Accuracy: Ensures identical sizing and other metrics across all products, making it highly repeatable and reliable for consistent quality.

- Versatility in Product Design: Capable of creating complex and intricate products, ranging from simple to complex shapes and in various sizes.

- Reduced Waste: This method excels in minimizing material waste during production.

- Fast Production Cycle: Features an incredibly rapid production cycle, enhancing overall efficiency.

- Automatic Operation: The process can be automated, reducing manual labor and increasing production speed.

- Variety of Options: Allows for a variety of colors and easy product replacement, accommodating diverse industry requirements.

- Complex Part Formation: Capable of forming parts with complex shapes, which might be challenging with other methods.

- Adaptability to Industry Needs: The injection molding machines used can simultaneously manufacture numerous silicone rubber products, meeting various industry standards.

Jution Silicone & Rubber Co., LTD provides LSR injection molding service for you. If you have any silicone products that need LSR injection molding service, please contact our molding technical expert to support you!

Custom LSR(Liquid Silicone Rubber) Injection Molding Service

What is compression molding?

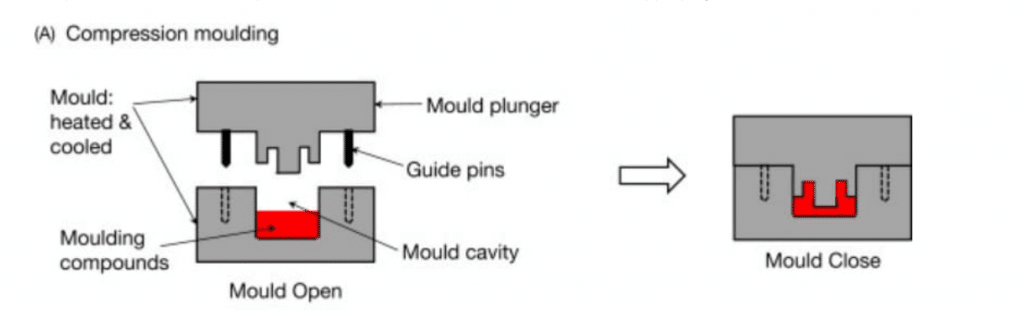

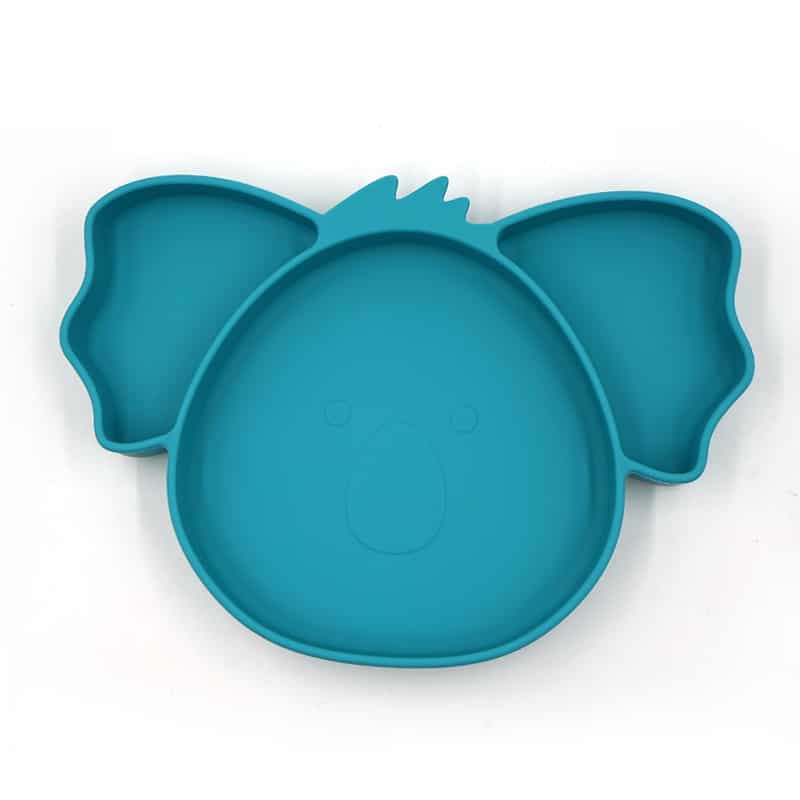

Compression molding uses heat and pressure to shape silicone products. The process starts with placing silicone in a heated mold that matches the final design. When the mold closes, pressure is applied, making the silicone fill the mold. Heat then cures the silicone, turning it into a strong, flexible material. After curing, the mold opens, and the finished part is removed. This method is efficient for creating precise, durable silicone parts and is widely used in industry.

During the flow of the molded material filling the mold cavity, not only the resin flows, but also the reinforcing material, so the molding pressure is higher than that of other processes, and it is a high-pressure molding. Therefore, it requires both a hydraulic press that can control the pressure and a metal mold with high strength, high precision, and high-temperature resistance.

This method is usually suitable for silicone rubber, thermosetting and thermo-softening plastics, as well as advanced composite materials. Compression molding employs a heated cavity and vertical press mechanism which makes the necessary tooling easy to construct and maintain. It can be used in both low and high-volume production.

Compression molding wastes less material than injection molding, as no runners, sprue, or gates are required to form the part. Consequently, this technique produces an aesthetically as well as functionally superior surface finish. It is the go-to technique for large flat and curved components. This molding technique outperforms other manufacturing techniques when composite materials are used to give extra stiffness, corrosive resistance, durability, and other special material properties.

Custom Silicone Compression Molding Service

Compression molding, like any manufacturing technique, has its limitations:

- Longer Cycle Time: The process typically takes longer compared to other methods.

- Complex Part Production: Highly intricate parts may be challenging to produce using this method.

- Flash Formation: Excess material, known as flash, can attach to the part during molding and requires removal in post-processing.

- Low Mold Cost: Despite these drawbacks, many clients prefer compression molding due to its lower mold cost.

Our Engineer will suggest what kind of molding is the best way to fit your silicone products.

The Process comparison

What is the process of injection molding?

The injection molding process should be from the mold design to the ejecting. Jution Silicone & Rubber Co., LTD has a professional mold and mechanical designer to help design the silicone tooling by Solidworks, pro-engineer、UG、AUTOCAD.

What is the process of compression molding?

In Jution Silicone Rubber we have more than 100 skilled worker run the compression molding for our clients. (From compression mold to the molding). If you have any silicone products that need the compression molding service, contact our sale expert.

The Material comparison

The first point of action for every manufacturing process is deciding the material to use for production. Likewise, material selection is a vital point of consideration when deciding between compression molding vs injection molding.

While both processes support a wide variety of plastics, they have some peculiarities.

What is the material used in injection molding?

The material options for injection molding include the following:

What is the material used in compression molding?

The materials used in compression molding encompass a diverse range, each suited for specific applications. Here’s a streamlined overview:

Thermosets:

- Characteristics: Thermosets can be liquefied only once and are not re-liquefiable post-solidification due to irreversible polymerization and cross-linking. They are non-recyclable and tend to smolder rather than melt under high heat.

- Applications: Despite their non-recyclability and disposal challenges, thermosets are suitable for specific applications due to their unique properties.

- Examples: Phenolic molding compound (Bakelite), Epoxy resin, Polyester (also available as thermoplastic), Polyurethane.

Thermoplastics:

- Characteristics: Thermoplastics can be repeatedly melted and reshaped. They are more sustainable in disposal and cost-effective.

- Examples: Polypropylene (used for foam), Nylon, High-density polyethylene, Polyester (as thermoplastic), PTFE.

High-Temperature Materials:

- Used as metal substitutes in certain applications, including Polyaryletherketones (PAEK), Polyetheretherketones (PEEK), and Polyetherketoneketones (PEKK).

Composite Materials:

- Glass Fiber: Mixed with resins to create composites that outperform the individual components.

- Carbon Fiber: Similar to glass fibers but more expensive and stiffer.

- Sheet Molding Compound (SMC): Glass fibers sandwiched between polymer resin layers, often polyester, with a typical thickness of around 5mm.

- Bulk Molding Compound (BMC): A mix of chopped fibers, hardening agents, and polymer resins, more malleable than SMC.

Elastomers:

Viscoelastic polymers with insulating properties and chemical resistance, used in various applications.

Our factory specializes in compression mold tooling and injection mold tooling. We primarily offer HTV silicone rubber for compression molding and LSR for injection molding, with additional materials sourced from partners when necessary.

The cost comparison

the cost of injection molding

Injection molding requires very high injection pressures. The mold must therefore be built to withstand these high pressures. This adds cost to the tooling. The tooling cost is around 1500 USD-20000 USD

When it comes to individual part costs, injection molding can produce inexpensive, complex parts. However, this process is only cost-competitive if production run volumes are large enough to spread the high cost of injection molding tooling over a sufficient number of pieces. When you have a silicone product you do not know which molding method is better for you, you can contact us to get more advice.

the cost of compression molding

Compression molding has cheaper tooling costs. The prototype tooling cost is around 199 USD-1999 USD. The mass production tooling cost is 999-9999 USD.

At lower volumes, compression molding is cheaper than injection molding due to the lower initial mold costs.

The advantage and disadvantages

Some of the advantages of injection molding over compression molding include the following:

Advantages of injection molding

- Allows you to be practical with your options

- Efficient and fast production of uniform components

- Ability to mold in tamper evidence features

- Enhances versatility and customization

- Low production costs

- Shorter lead time

- Solid and durable final products

- Supports complex mold designs

- Tolerates a wide range of materials

- No need for post-processing

Disadvantages of Injection Molding:

- Here are a few cons of injection molding that you need to take note of:

- High tooling cost

- Small numbers of productions are usually costly

Advantages of Compression Molding

Why do manufacturers choose compression molding techniques for certain projects? There are several advantages to this process that make it the right choice for certain objects. Those benefits include:

- More cost-effective for small production runs compared to injection molds as tooling is typically less expensive. Ease of maintaining mold tooling. Low initial tooling costs and investment

- Good results for products with varying thicknesses.

- Support of thermoset materials vs thermoplastic materials for injection molding.

- Enables more efficient color changeovers

- It preserves the mechanical and chemical properties of materials

- Ensures better visual appearance by avoiding gate vestige

Disadvantages of Compression Molding

- Not well suited for complex parts or large production runs

- Products may show odd parting lines,Slower part production time. Compression molds take longer to produce finished parts and the additional time necessary for removing flash adds to cycle times.

- Secondary machining may be required after compression molding

- Reduced molding depth.Excessive waste and extra processing. The overflow or “flash” on a compressed item must be cut away before the item is ready for use. This flash often cannot be recycled easily.

- Extra startup and maintenance costs.

The Application comparison

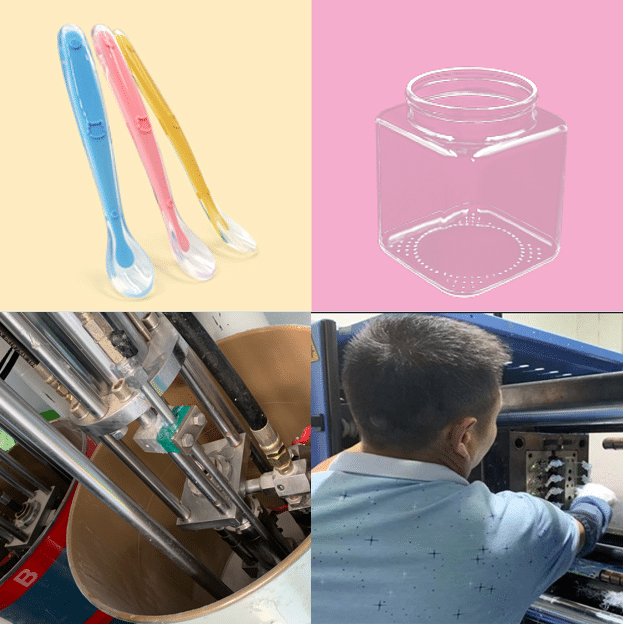

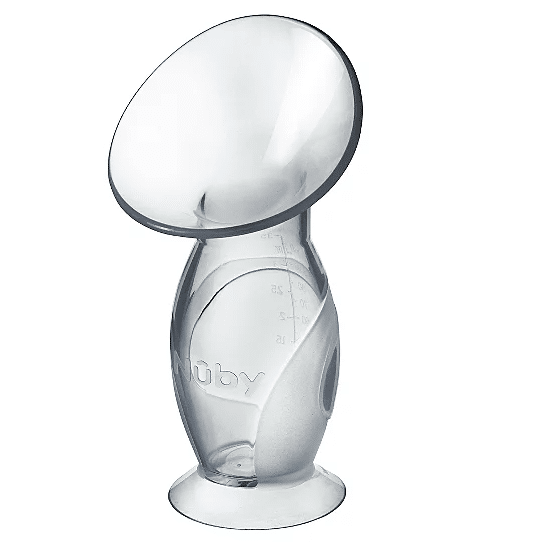

Injection molding Applications

Injection molding is frequently utilized for a range of applications due to its adaptability. The procedure can be used to improve everything from medical silicone components to tiny, delicate auto parts. Other instances of applications include:

Compression Molding Applications

Compression molding is ideal for manufacturing stronger, more durable parts. Today, the process is often central to the creation of automotive and appliance parts. Other applications include:

How to choose the right process of Injection molding VS Compression Molding?

So, the real question here isn’t which will you choose, it’s WHY will you choose it? Compression molding and injection molding each have their advantages and disadvantages, but who reigns supreme depends on what you’re producing.

It’s important to select a manufacturer like jution silicone rubber who understands which technique best suits your part, as that should be the deciding factor. Regardless of which one is better suited, has the capabilities to cover both your compression and injection molding needs.

Reach out if you have a project that needs jution silicone rubber expertise and supply chain solutions!

Conclusion

According to this article, you will know more information about the injection molding VS compression molding. When you have a silicone product need to molding, contact Jution expert. Our skilled Engineer and workers will offer the one stop service from the silicone mold tooling to the finished silicone products for you.