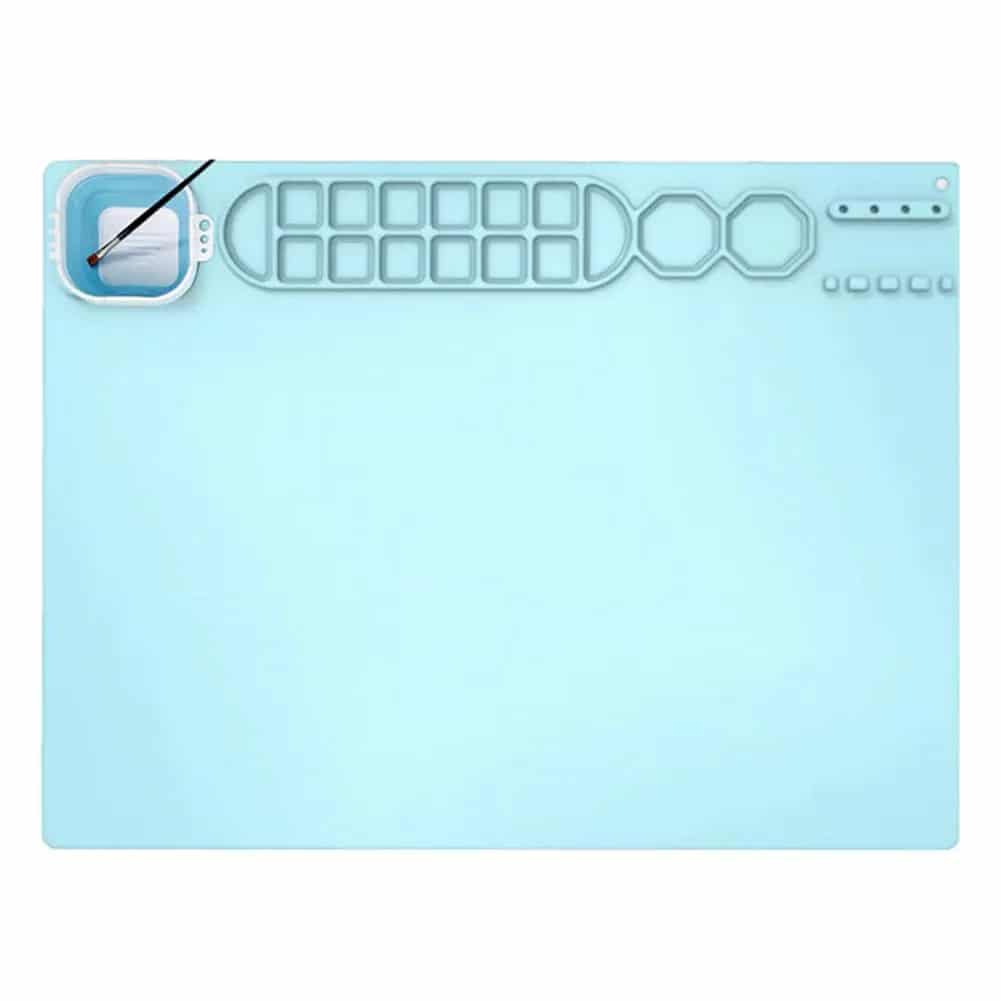

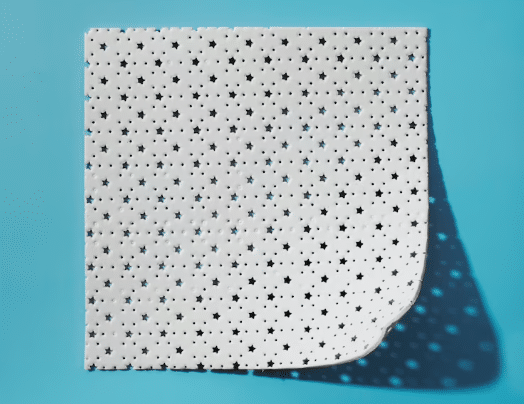

Custom Silicone baby mats

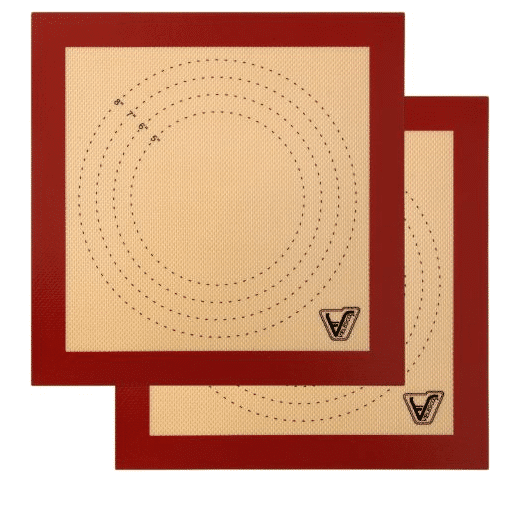

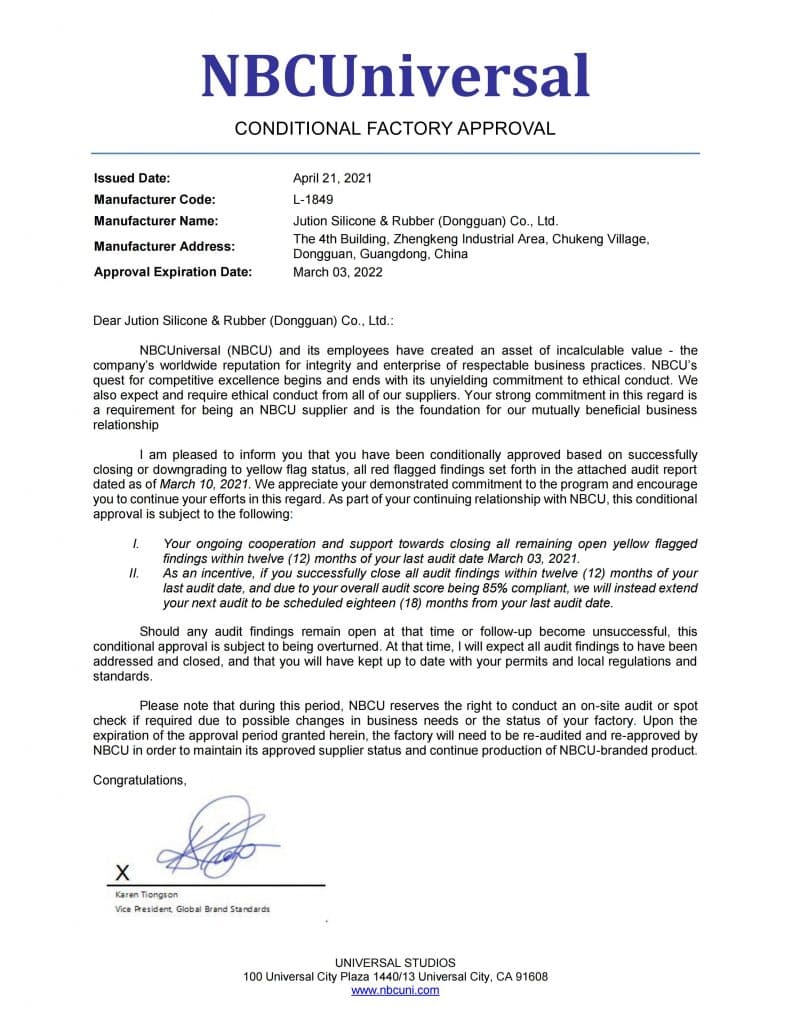

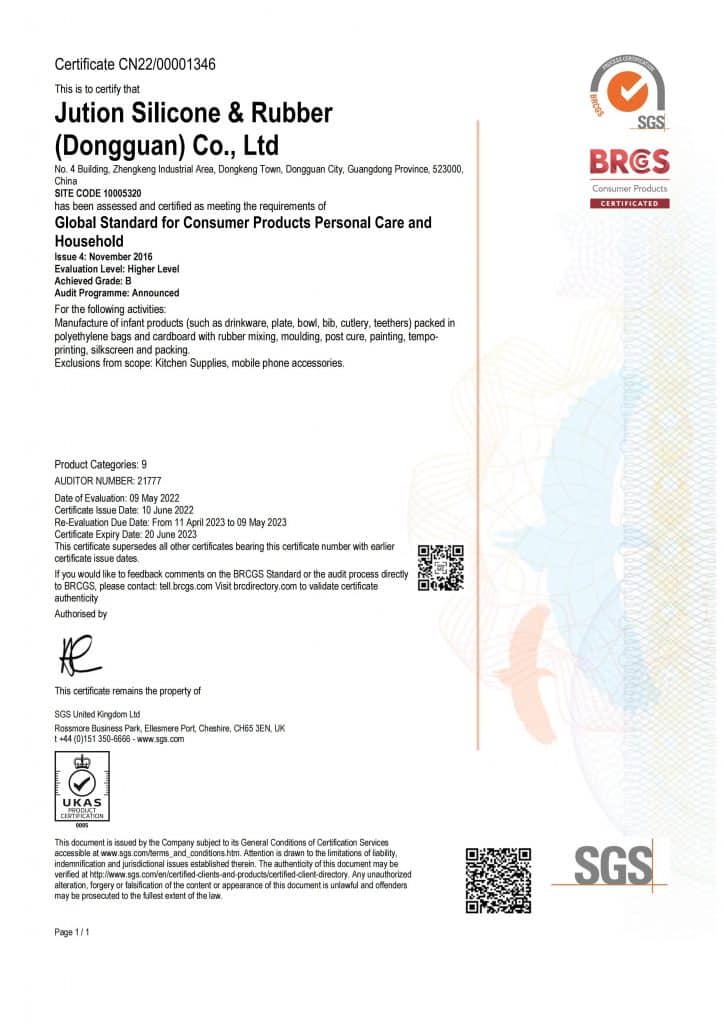

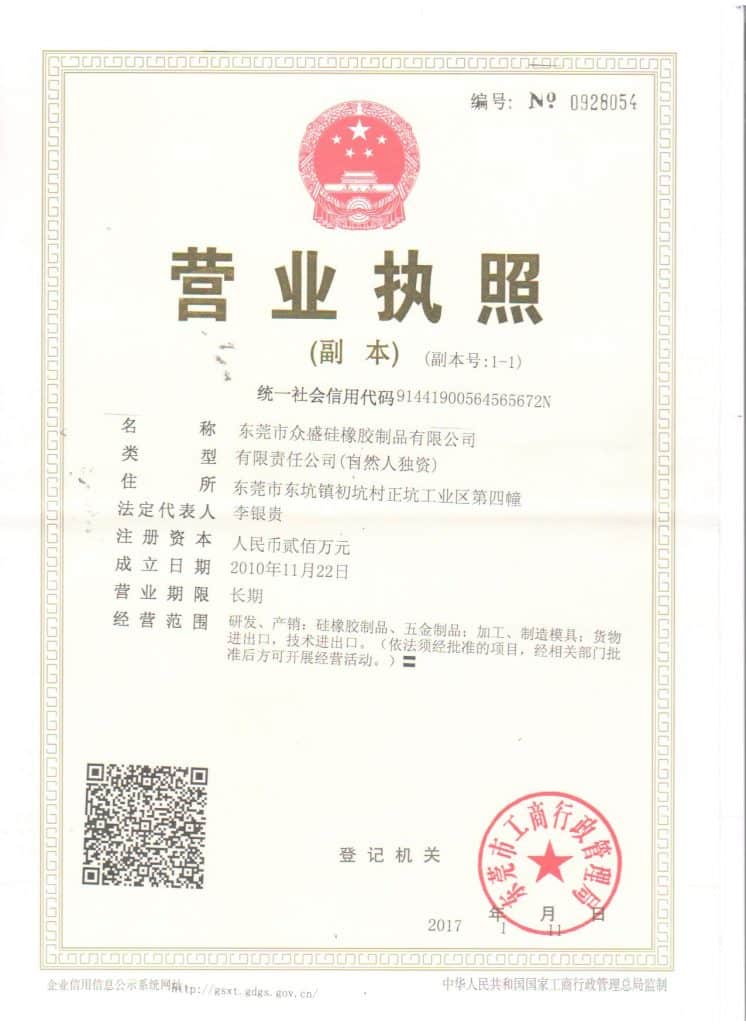

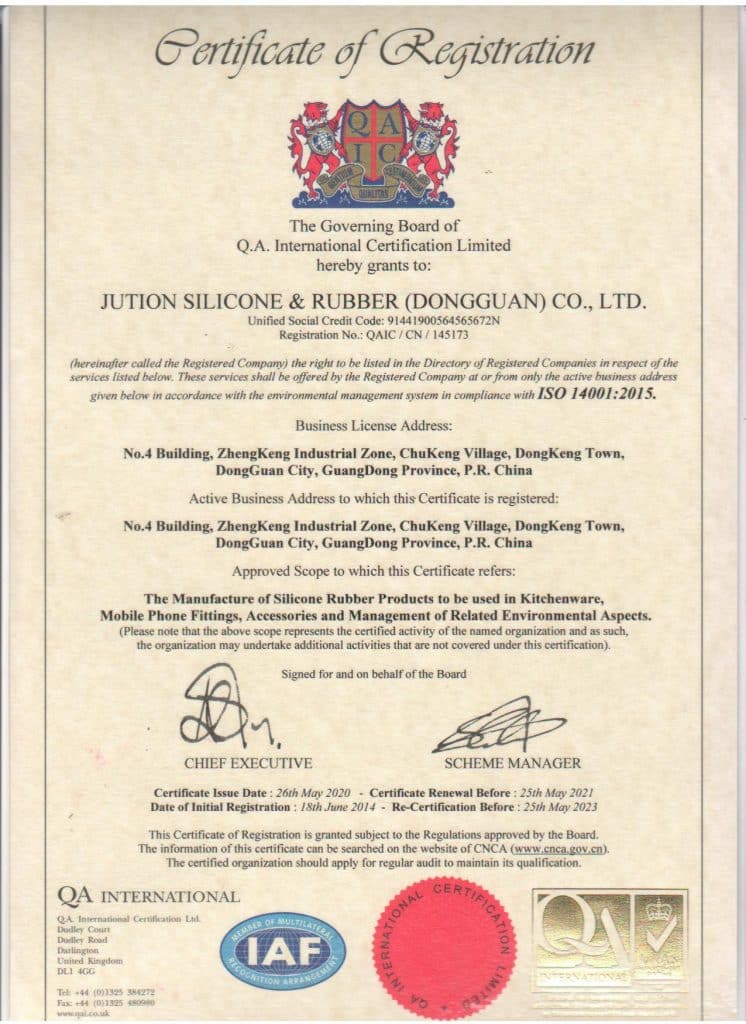

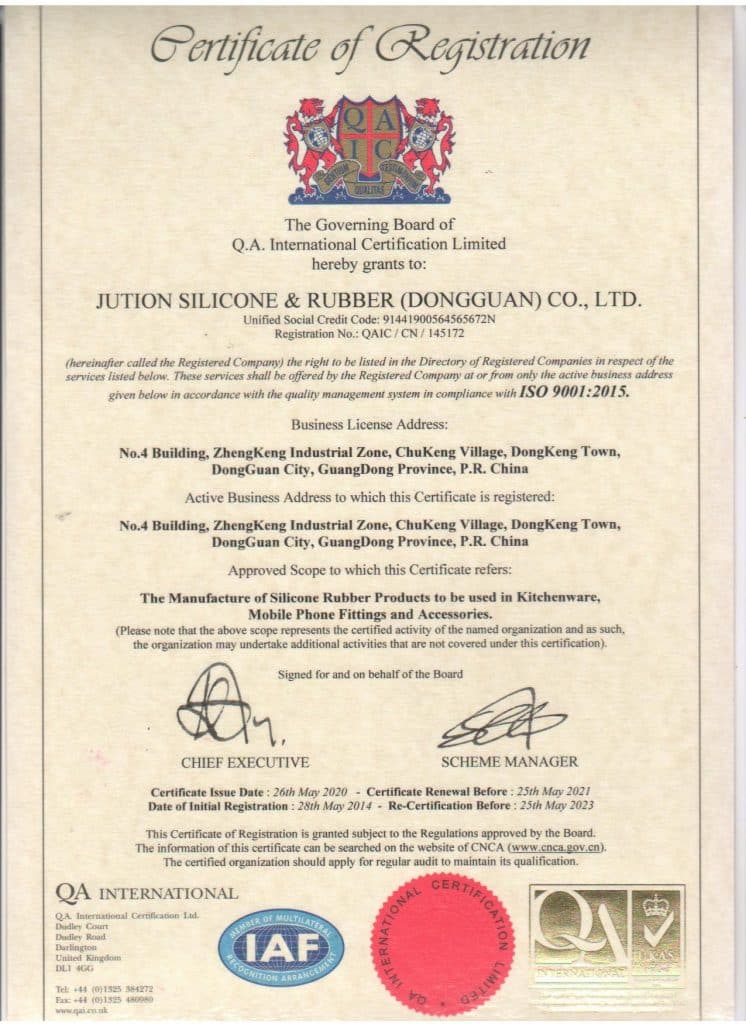

Jution silicone is a professional custom silicone baby mats manufacturer, offering safe, soft, and easy-to-clean baby mats for feeding and play. Our mats are made from 100% food-grade silicone, with full OEM/ODM customization including different shape, sizes colors, and designs logos, and packaging — ideal for brands, retailers, and distributors.

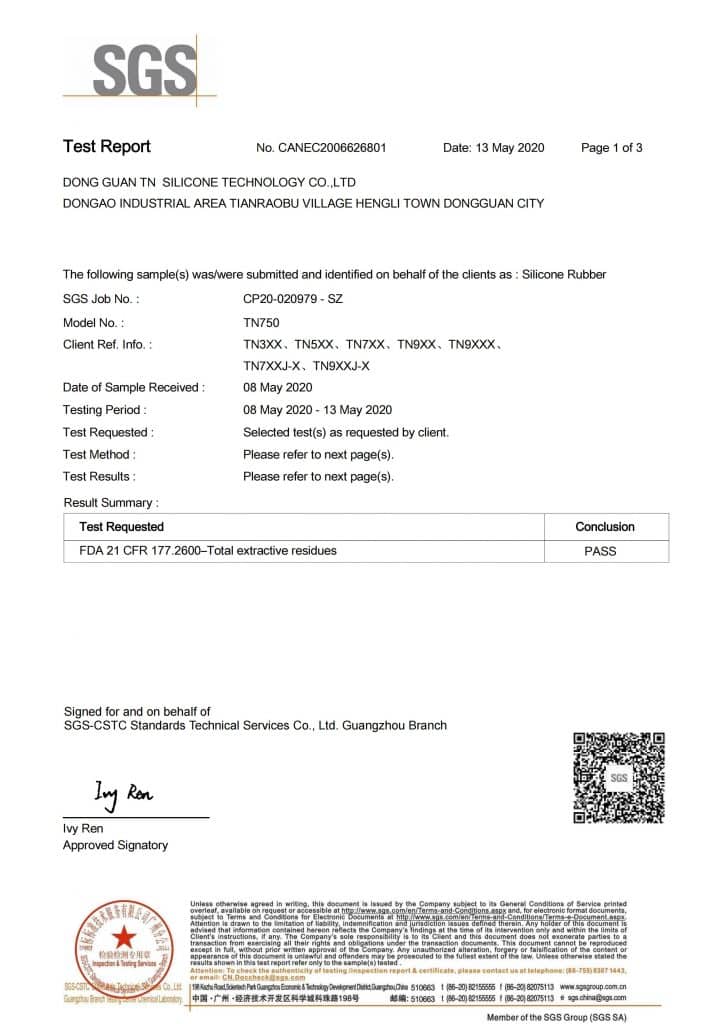

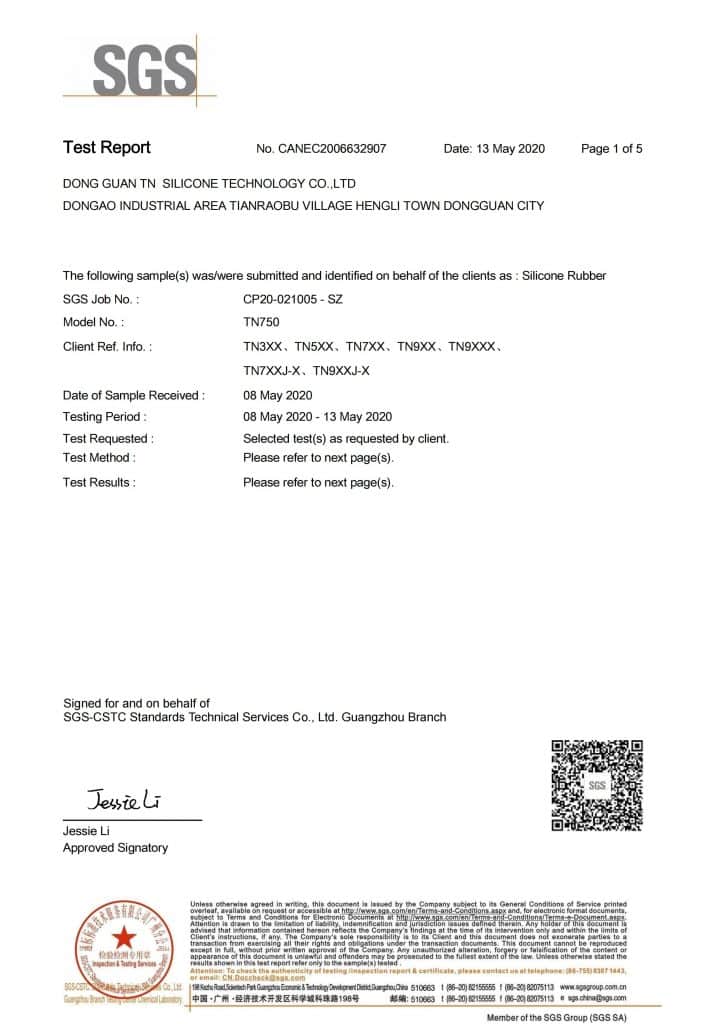

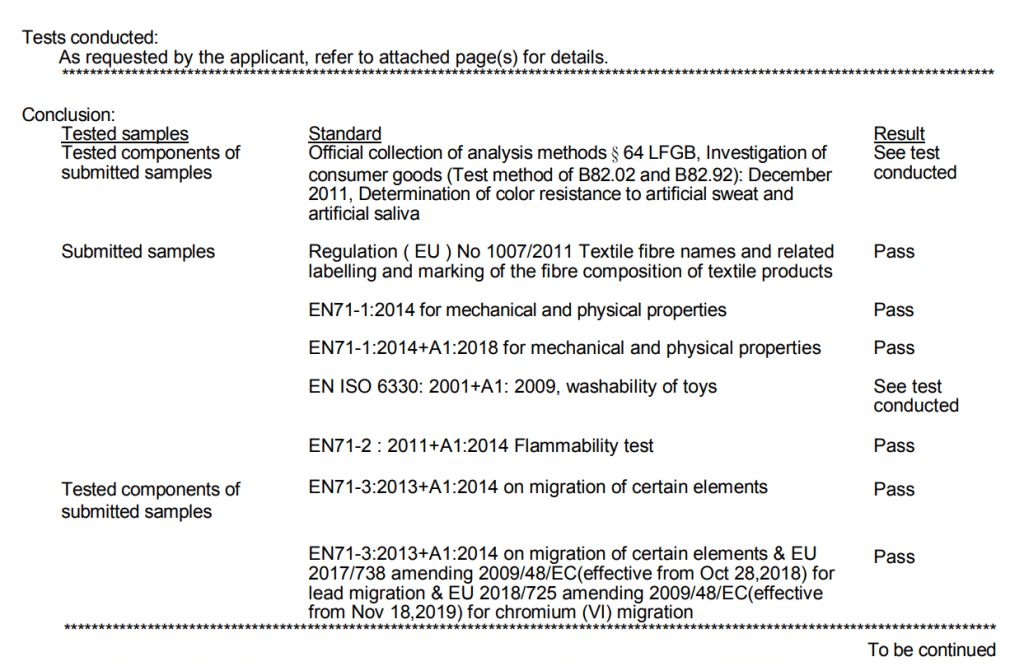

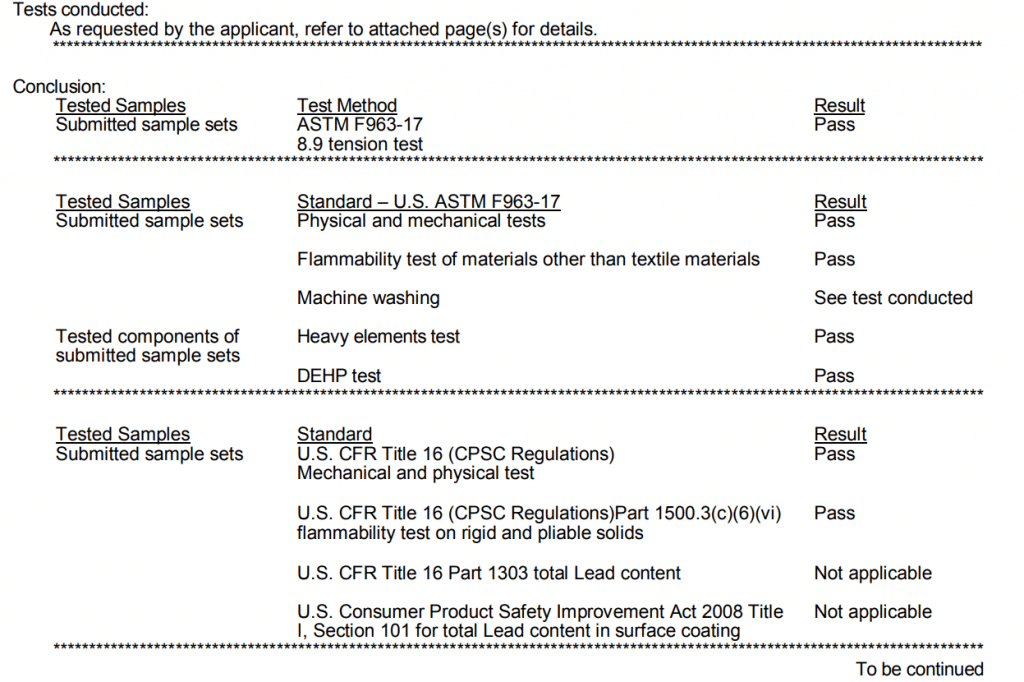

These baby mats are made from 100% food-grade silicone and are non-toxic, BPA, PVC, phthalates, lead and cadmium. All the silicone baby mats can pass FDA 21, CPSIA, CP65 (USA Standard), §30 and §31 LFGB, EN-71 (EU Standard) or Others if needed.

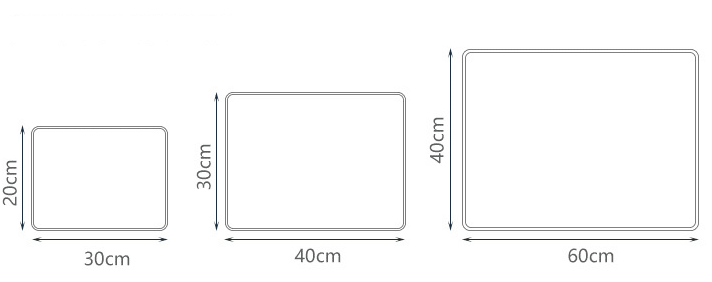

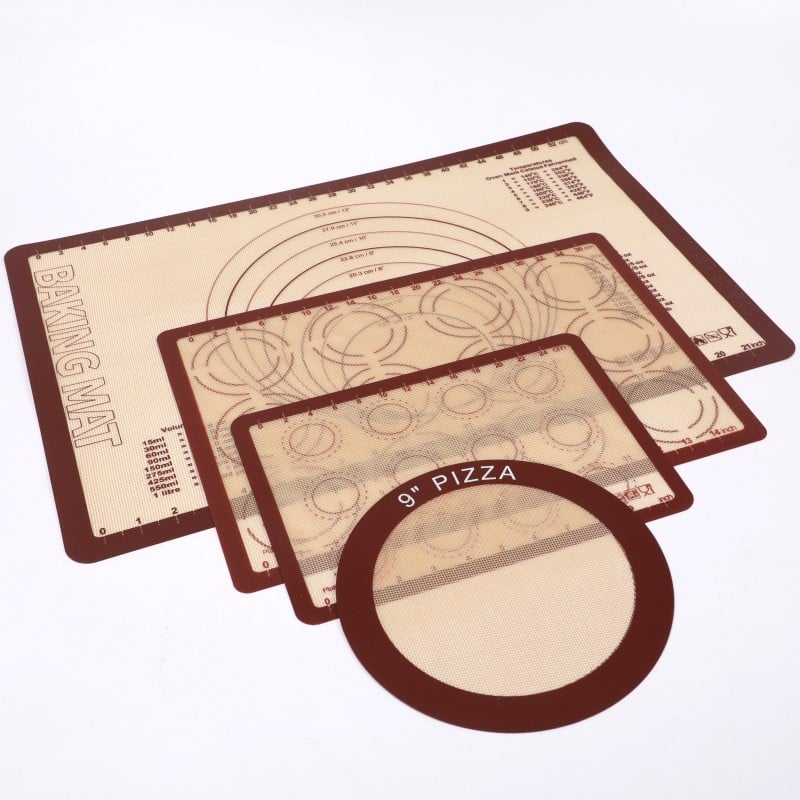

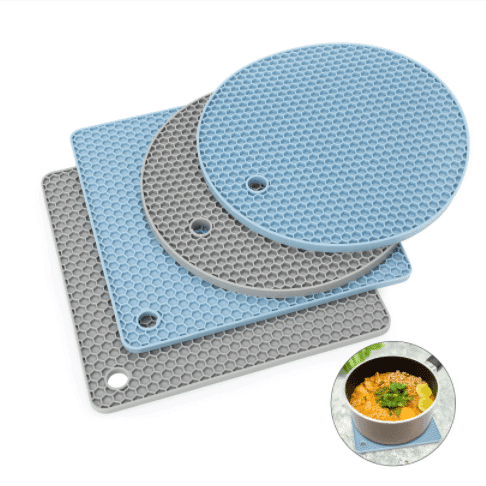

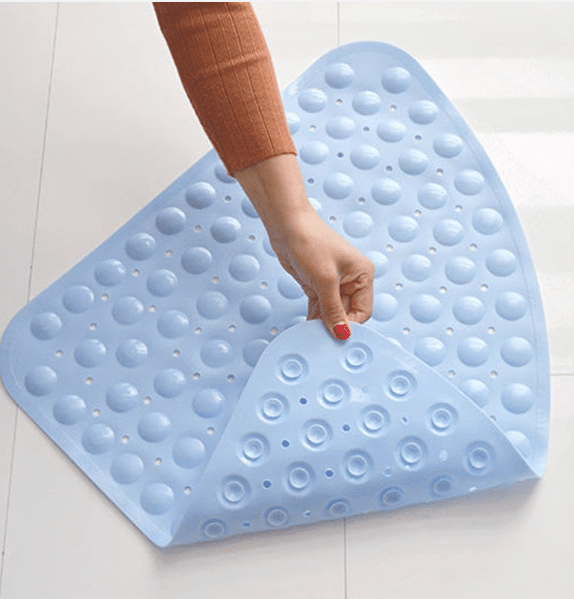

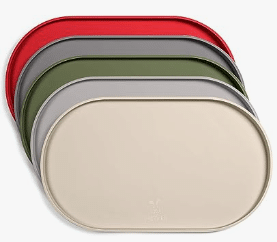

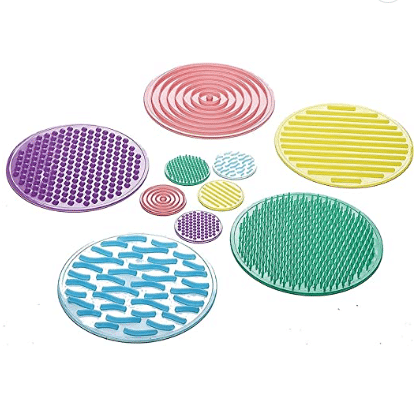

Custom silicone mat shape, size

As a leading of silicone mats supplier. You can customize the silicone mats size, the length from 20-360 CM, The width from 20-120 CM. The thickness from 0.05-5 MM. The shape( With lip, belt, suction cup, etc, elephant, bear, bunny,Round, Square, Rectangle, Oval etc, and embossed and debossed logo by opening the new tooling.)Suction base or anti-slip design.

Common products

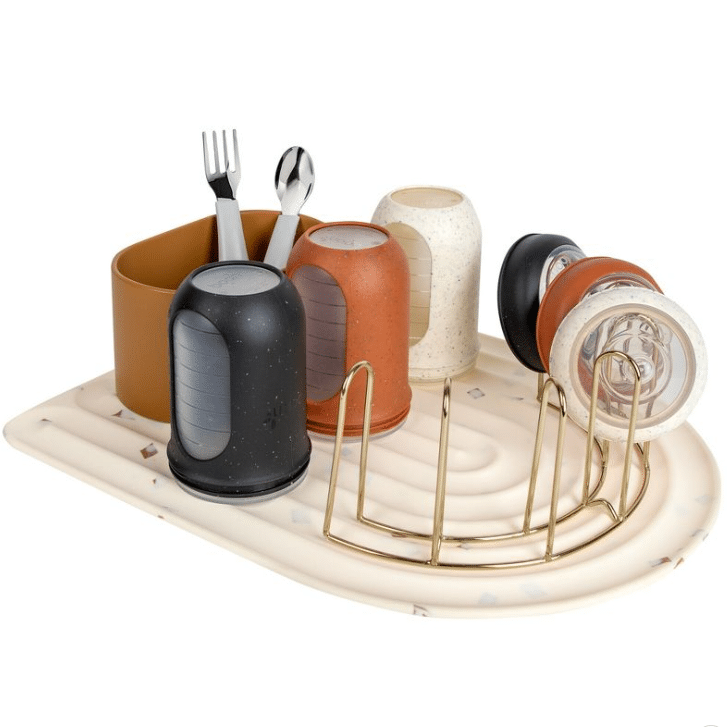

The silicone baby mats Jution made are widely used in :Baby feeding placemats,Toddler learning & activity mats,Restaurant, home, daycare use,Retail-ready baby gift sets.

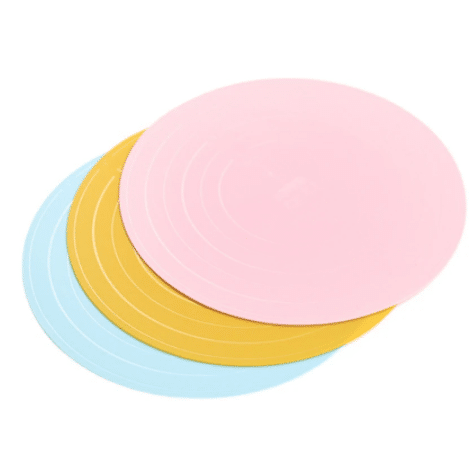

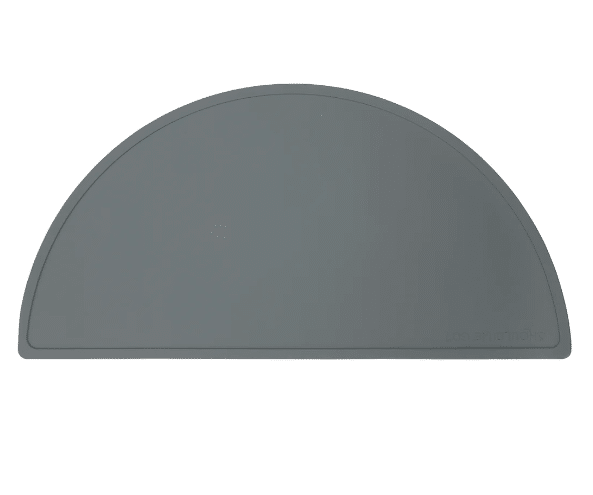

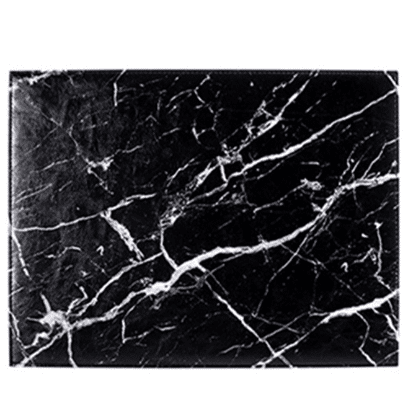

Custom silicone mats color

You can customize the baby mats’ color according to the Pantone book or the common color that we used. And also make the double color and marble color silicone mats for you if you needed

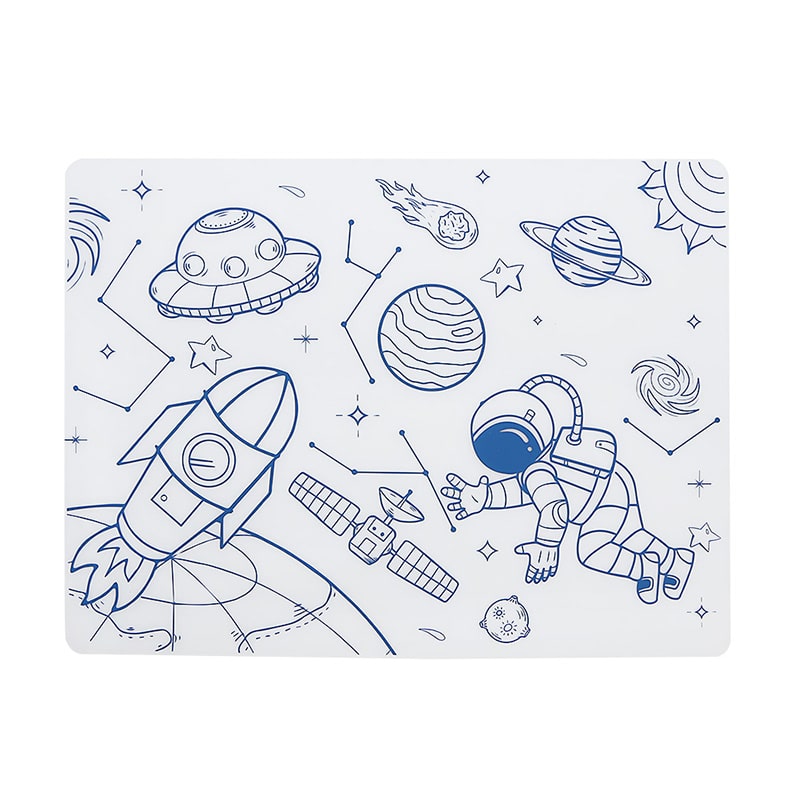

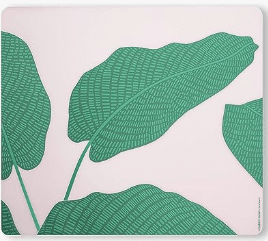

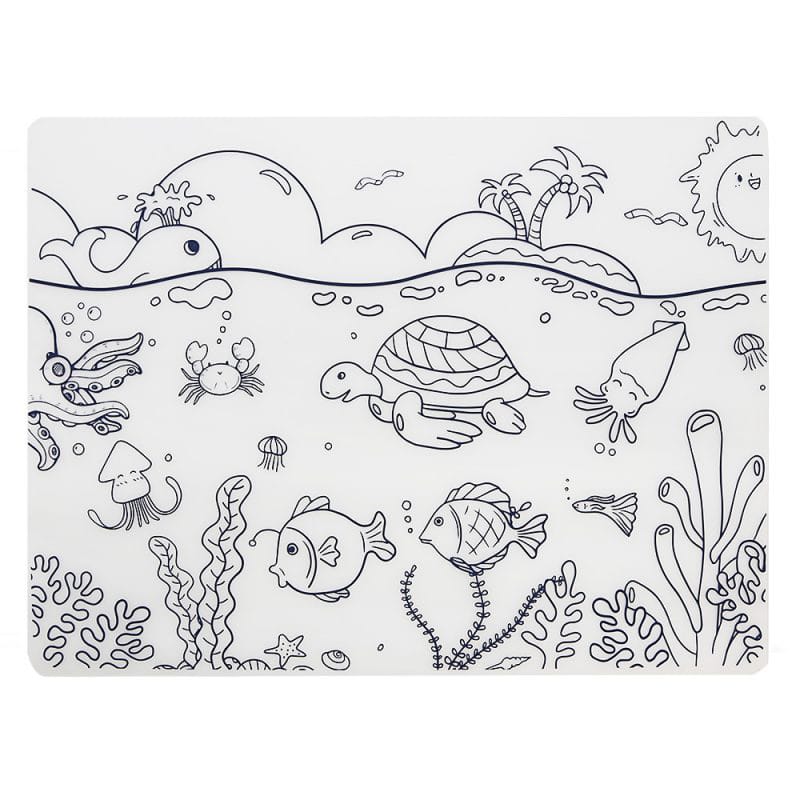

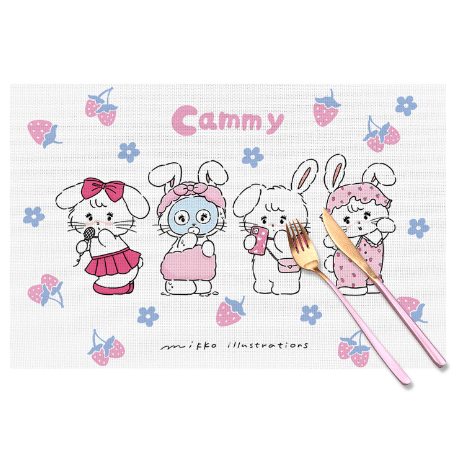

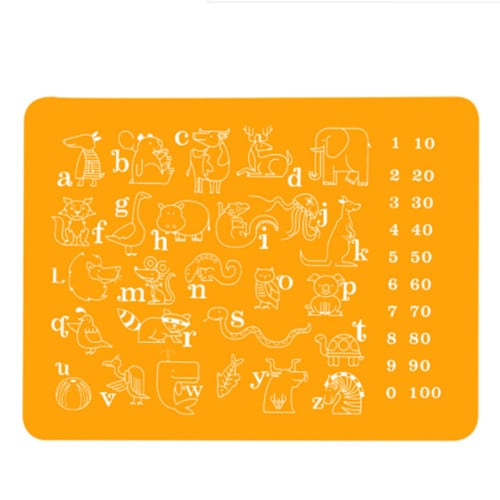

Custom silicone Mats pattern and Logo

Custom the silicone mats pattern: You can customize the silicone baby mat pattern pattern with Printing depending on the pattern, color, and area by:

Jution provide customized packaging solutions for manufactured silicone baby mats. We offer one-stop services such as helping customers to design, develop, assemble and inspect the packaging, ensuring the appearance of finished products are Baby-safe packaging design.

If you are not sure which logo or pattern is more suitable for your project, you can contact our experts for consultation or custom samples.

Common products

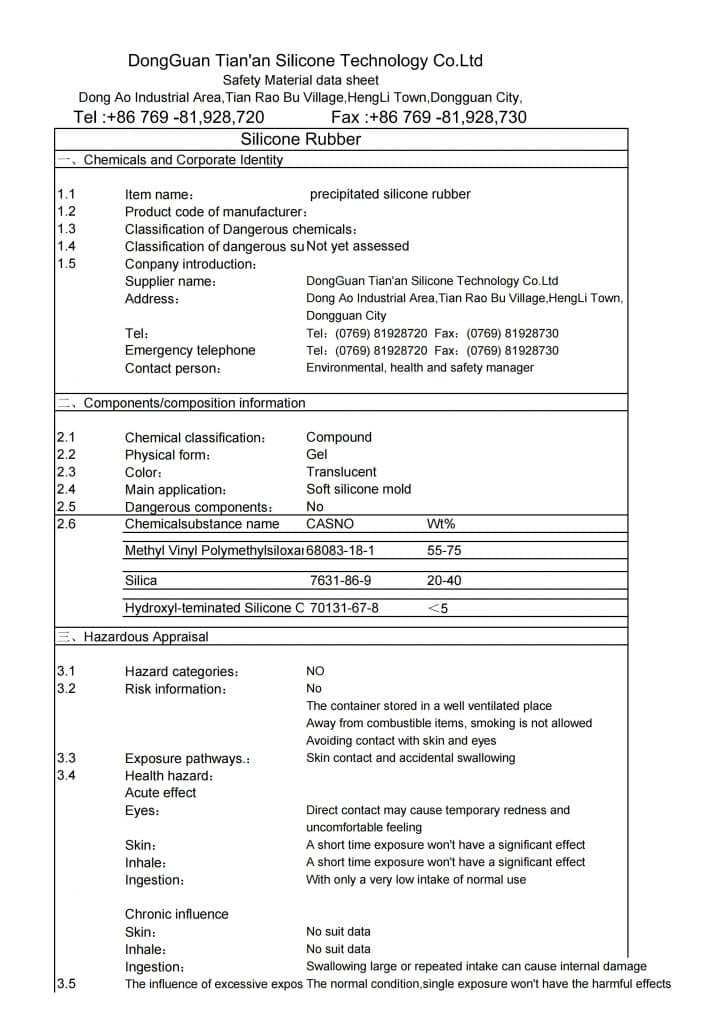

Silicone baby mats Material

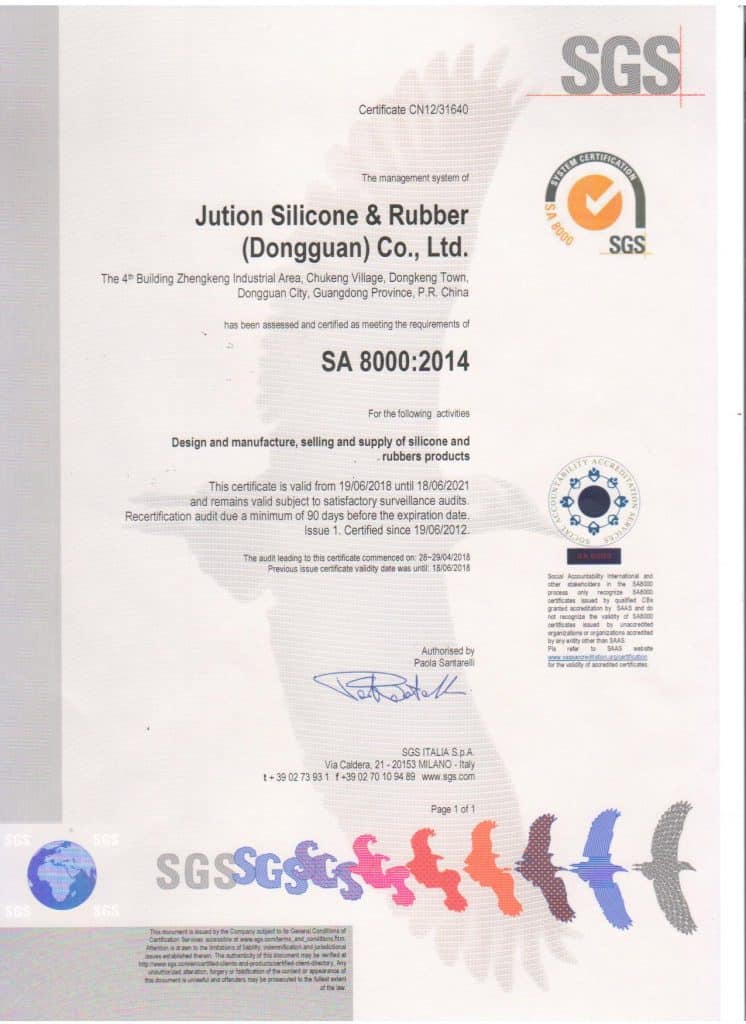

In Jution Silicone, For the baby mats products. The material that we used for all SGS tests FDA/LFGB/PAHS/REACH/ROHS/VOM approved approved. The silicone baby mats can be produced by HTV(HCR) Silicone Rubber or LSR Silicone.

For order quantities less than 50,000 pieces, We recommend our clients use the Fumed silicone rubber with platinum agent

Specification

When you need high volume more than 50,000. We recommend you use the LSR Material with platinum agent.

Jution offer the custom silicone baby mats in Fast sampling (5–7 days) ,Small MOQ 100 pcs support for startups.

Contact us to create safe, stylish, and brandable silicone mats for babies and toddlers.

Product (Silicone Baby mats)

Let every baby in the world use safe and eco-friendly silicone products

The safety of silicone baby products is our top priority for us.We believe that all mothers hope to use high-quality baby products for their babies.

People Also Asked:

Still Have Questions?

If you cannot find an answer to your question in our FAQ, you can always contact us and we will be with you shortly.