Injection molding vs extrusion molding

Both extrusion and injection molding are common silicone products production processes. However, there are significant differences between the two methods pertaining to the process fundamentals, compatibility, strength, and precision. All these factors combine to affect the overall cost and time of the process, which in turn affects the overall costs and capabilities of both methods.

- Injection molding is suitable for three-dimensional product manufacturing whereas extrusion molding is only suitable for two-dimensional product manufacturing.

- Injection molding is the oldest silicone manufacturing process whereas extrusion is comparatively new.

- Atypical cross-sections can be achieved by extrusion. However, injection molding may demand intricate dies to achieve the same.

- Injection molding offers strength to products, whereas extruded products are comparatively weaker.

- Injection molding is considered expensive due to costly die requirements. Yet this process is the most utilized due to its efficiency.

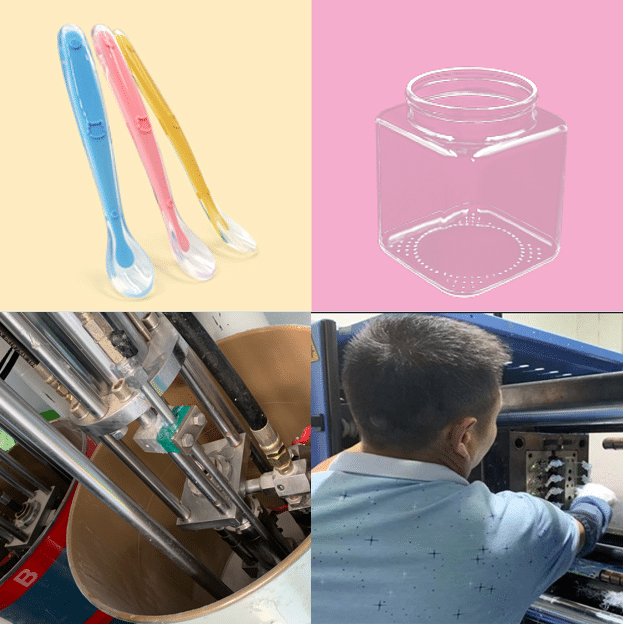

Custom LSR(Liquid Silicone Rubber) Injection Molding Service

Custom Silicone Extrusion Molding Service

There is a significant difference between injection molding and extrusion when it comes to cost. Injection molding is generally more expensive and most of it is because of the mold costs. The mold needs to be either machined or 3D printed depending on the design’s complexity.

Furthermore, the material also plays a significant part in determining the cost of injection mold. The better the material, the longer will the mold last but that will come at a cost. Injection mold typically has a higher, initial design cost due to the complexity of the mold structure. Its cyclical production, however, typically creates a finished piece that often does not require further assembly or secondary processing.

The extrusion process, on the other hand, is much simpler and handles 2D shapes without any intricacies. As a result, the operating costs of the process are lower but remain unaffected by economies of scale. Moreover, the overall setup costs for extrusion can be quite high considering the restriction on complex designs.

The EXTRUSION method can create complex cross-sections such as multi-lumen tubing used in medical devices or food processing. The surfaces of extruded materials are smooth and do not require post-production “clean-up.” Extrusion is ideal when a variety of lengths of the same profile shape is required. By producing a stock product with a continuous production process and cutting to length post-process per demand, setup and die/design costs are reduced for similar items.

Both injection molding and extrusion work well with silicone. However, injection molding is more suitable for complex closed 3D shapes, like vehicle interior room components. These silicone components have a complex initial dye which significantly increases the capital costs but remains operational for many cycles.