Laser Engraving Patterns or Logos on Silicone Products

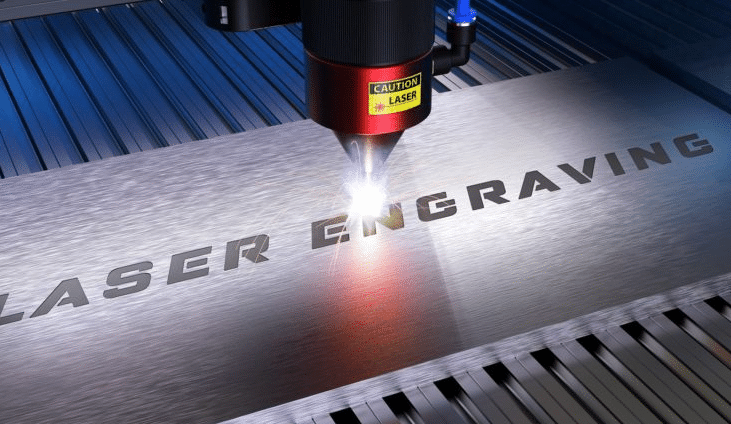

Laser engraving is the most popular laser marking technology in product identification and traceability. It involves using a laser marking machine to make permanent markings on different materials. Such as silicone baby products, silicone baby bibs, silicone baby mats, etc.

What is Laser Engraving?

The word “laser” is actually an acronym that stands for “light amplification by stimulated emission of radiation.” When used for engraving, it works kind of like a chisel, etching permanent letters, numbers, or symbols into the material. Laser engraving is commonly used on metal, wood, glass, stone, fabric, tile, or silicones.

Laser engraving is the process of selectively removing microscopic layers of material, thus creating visible marks on the treated surface. Depending on the materials, the laser-material interactions can be different. On harder surfaces, the mechanism of action is primarily ablation where the focused beam of laser dislodges microscopic particles from the substrate. Engraving can achieve a depth of 100μm and beyond, whereas laser marking is typically shallower.

The process is suitable for marking logos, barcodes, serial numbers, and QR codes on silicone products. Alongside laser etching, annealing, ablation, and other laser marking technologies, the process forms a set of highly reliable processes in traceability, identification, and product decoration.

A Brief History Of Laser Engraving

Laser engraving’s history cannot begin without talking about manual engraving. Manual engraving is a process that involves using a sharp object (engraving tool) to inscribe a marking on the part. For example, stones were engraving tools about 500,000 years ago. Currently, the oldest manually engraved part dates to about 500,000 years ago.

The date laser etching was invented is unknown but we know that laser engraving was reported to be used for the first time in 1978.

Manual engraving evolved over the years due to technological advancement. The beginning of the laser engraving process would be premised on Albert Einstein’s idea of LASER 1916 and its optimization in the 1950s. Theodore Maiman created the first optical laser. Gordon Gould would be credited with making the original laser light.

Laser became an important part of drilling when Western Electrics made the first laser machine in 1965. However, its real use in engraving wouldn’t be until the advent of CO2 lasers in 1967. Further technological advancement has led to the development of other types of machines applicable in engravings, such as UV and MOPA laser markers.

1978 – The first laser engraver, although in its primitive form, is purchased. It is used to create works of art on wood.

1996 – The first software designed specifically for lasers is created. Computers are eventually directly integrated into laser engraving machines.

From that point on, laser etching and laser engraving began being used more widely to engrave personal items and to implement modern traceability in production lines.

How Does Laser Engraving Work?

Laser engraving is a process that vaporizes materials into fumes to engrave permanent, deep marks. The laser beam acts as a chisel, incising marks by removing layers from the surface of the material. The laser hits localized areas with massive levels of energy to generate the high heat required for vaporization.

Very simplified…light is concentrated over and over again to create a powerful beam. There are three major factors to how this works: Concentration, Energy, and Direction.

Laser engravers are specifically designed to focus laser light for the purpose of marking wood, metal, glass, or some other material with a preselected engraving—often images or script. The machine uses lasers to produce concentrated heat that removes the top layer of material, cutting it from an item to create the desired design. Using powerful lasers and mirrors, the machine reflects a laser beam onto a surface of an object.

The light is focused at the right distance and set to the right power level in order to leave a mark. Too little power and it will not end up cutting into the material, too much and you can burn through the object. Some lasers are mounted on a track and make passes over the desired engraving area similar to how your ink printer prints on paper. The pro of this kind of laser is you can engrave larger areas. Others lasers are stationary and focus on a smaller surface area. The pro of this laser type is it tends to engrave faster at higher powers.

The Laser engraving logo does not involve the use of inks, nor does it involve tool bits which contact the engraving surface and wear out, giving it an advantage over alternative engraving or marking technologies where inks or bit heads have to be replaced regularly.

How to print on silicone Products?

Water Transfer Printing Pattern or Logo on Silicone Products

Pad Printing Pattern or Logo on Silicone Products

How to Print Logo or Pattern on Silicone Bibs?

Screen Printing: Print Patterns On Silicone Products

Heat Transfer Printing Process: Print Patterns On Silicone Product

What Are The Steps Of Laser Engraving?

Different Types Of Laser Engraving

There are three types of laser engraving: Etching, deep laser engraving, and laser ablation, the difference between the three is what the surface is and how much you remove

- Laser Etching: 0.0001 in. Depth

- Laser Engraving: 0.0001 – 0.005 in. Depth

- Deep Laser Engraving: > 0.005 in. Depth

Laser Engraving service

JUTION provides professional Laser Engraving services. We can perform Laser Engraving of logos and patterns on various silicone products according to user needs.

If you need a clear and high-definition pattern or logo that is the same color as the substrate, we recommend using Laser Engraving service.

Advantages And Disadvantages Of Laser Engraving

Advantages of Laser Engraving:

- The high precision it offers allows for engraving more detailed images and having cleaner cuts.

- The production speed is higher.

- A wide range of materials are cuttable without damaging them.

- It’s a more affordable option compared to CNC machines.

- It’s compatible with any vector software like AutoCAD (DWG) or Adobe Illustrator (AI).

- It doesn’t generate waste like sawdust.

- It’s very safe to use with the right equipment.

Disadvantages of Laser Engraving:

- Thicker materials are more difficult to cut or require very low speeds.

- Higher-density materials like glass can’t be cut.

- It burns the edges of any material you want to cut.

- Some materials, like plastic, can produce toxic emissions.

- Production speeds aren’t always consistent, depending on the material’s thickness and density.

- Some laser cutters consume a lot of energy, increasing the production cost.

Laser Engraving Tips

1. Focused and flat.

The optic lens which the laser beam passes through focuses the beam down to a small point. In most cases the focal point should be set to the top surface of the material being engraved. This ensures the smallest and most precise beam is removing material during the engraving process.

Generally, the best materials to engrave are those with a single flat surface. However, surfaces with slight variations or arcs in them can be engraved successfully.

However, some materials are more forgiving and will not show variation in focus. Wood is a good material where you can have some variation in flatness and still get beautiful results!

2. Take time for test engravings.

For materials that you are not familiar with or do not have a settings file, run a small test on a piece of scrap material to assess your settings. Usually, it only takes an inch or so of the engraving to let you know if the quality and clarity is up to your standards. Then, you can adjust the power, resolution or other miscellaneous settings before running the final job.

3. Choose a high-quality image.

One of the most common issues with laser engraving is image quality. If you start with a poor-quality image, it is almost impossible to get a good engraving. If there is any blurriness or pixilation, the engraving will not have sharp, clean lines.

Frequently Asked Questions About Laser Engraving

How long does laser Engraving logo or pattern last long?

The engraving is typically permanent and will last as long as the silicone products itself.

Can Laser Engraving be used in Silicone baby products?

Yes, Laser Engraving can be used on silicone baby bibs, mats or any silicone products to create unique and personalized designs.

What is the difference between Laser Engraving compare Screen Printing, Heat Transfer Printing, In-Mold Decoration?

No Ink, Same as products color and material.

What is the cost of Laser Engraving?

0.05USD-0.2USD depend on the size and shape.

Conclusion

Laser Engraving is a versatile and cost-effective way that can be used to create high-quality logos or marks on various substrates, including silicone baby products. With the right equipment, materials, and techniques, you can create beautiful and long-lasting designs that are sure to impress.