Heat Transfer Printing process: Print Patterns On Silicone baby Products safely

Introduction

Heat transfer printing is a popular printing method used to create designs on various materials, including fabric, paper, plastic, and even silicone baby products. This printing method involves using heat and pressure to transfer a design onto a surface, resulting in a permanent bond between the design and the material. Silicone heat transfer printing is also one of the processes with the highest complaint rate and rework costs, mainly due to: 1. Easy peeling of patterns from the silicone products, 2. Hardened texture and plastic label feel at the printed area, and 3. Color differences in mass-produced for the printed patterns.

In this article, we will explore the basics of heat transfer printing, including what it is, its history, how it works, different methods, advantages and disadvantages, applications in various industries, equipment and materials required, tips for achieving high-quality prints, and frequently asked questions with real-world application scenarios of infant and toddler silicone products, systematically deconstruct the value, risks, and correct usage of heat transfer printing technology, helping brands, product managers, and purchasing personnel make more rational decisions.

Among all pattern presentation methods, heat transfer printing is becoming the preferred solution for more and more infant and children’s brands when creating cartoon patterns, soft colors, and IP images. Infant and children’s silicone products (such as silicone bibs, silicone placemats, silicone feeding bowls, and suction plates) are gradually evolving from “functional products” into comprehensive carriers of “design + emotion + brand value.”

What determines whether an infant and children’s silicone product is trusted by consumers and whether it leads to repeat purchases is no longer just the material itself, but the overall performance of “material + process + safety details.”

What is Heat Transfer Printing?

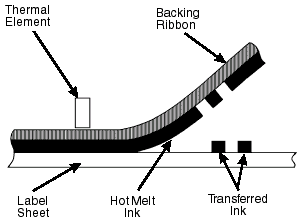

Heat transfer printing is a printing method that involves transferring a design onto a surface using heat and pressure. The design is printed onto transfer paper using a special type of ink, then transferred onto the surface using a heat press. The heat and pressure applied during the transfer process cause the design to bond with the material, resulting in a permanent, high-quality print.

From wiki

Heat transfer printing for baby and children’s silicone products refers to a printing method where the pattern is first printed on a special transfer film, and then the pattern is stably transferred to the surface of food-grade silicone products through precise control of temperature, pressure, and time. This process is commonly used to create cartoon patterns, soft color schemes, and licensed IP images, and is widely applied to infant and children’s silicone bibs, placemats, feeding bowls, suction plates, and other baby products..baby products industry, It must balance design expression, material safety, durability, and regulatory compliance.

A Brief History of Heat Transfer Printing

Heat transfer printing has been around since the 1950s when it was primarily used for transferring designs onto fabric. Over the years, advancements in technology and materials have made it possible to use heat transfer printing on a wide range of substrates, including silicone baby bibs.

How Does Heat Transfer Printing Work?

Heat transfer printing works by using heat and pressure to transfer a design onto a substrate. The design is printed onto transfer paper using a special type of ink that is compatible with the substrate. The transfer paper is then placed onto the substrate, and the heat press applies heat and pressure to transfer the design onto the substrate. The heat and pressure cause the ink to bond with the substrate, resulting in a permanent, high-quality print.

How to print on silicone Products?

Water Transfer Printing Pattern or Logo on Silicone Products

Pad Printing Pattern or Logo on Silicone Products

Laser Engraving Patterns or Logos on Silicone Products

How to Print Logo or Pattern on Silicone Bibs?

Screen Printing: Print Patterns On Silicone Products

Different Types of Heat Transfer Printing Methods

There are different types of heat transfer printing methods, including:

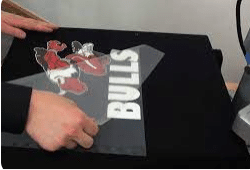

Plastisol transfer printing

Plastisol Transfers are screen-printed designs that are printed on a unique heat transfer (release) paper rather than screen printing directly to a garment. Once the design is screen printed onto the sheet, the printed heat transfer sheets are ready to be transferred onto any garment (t-shirts, sweatshirts, hats, etc.) with a heat press.

Sublimation transfer printing

Sublimation shirt printing is a specific process of printing that first involves printing onto a special sheet of paper, then transferring that image onto another material (usually polyester or a polyester mix). The ink is then heated until it disintegrates into the fabric.

Laser transfer printing

Laser Transfer Printing is a laser-based solution for digital printing with ceramic pigments. Ceramic colors can be transferred to flat glass with previously unknown precision.

Inkjet transfer printing

Inkjet transfer or inkjet photo transfer is a technique to transfer a photograph or graphic, printed with an inkjet printer onto textiles, cups, CDs, glass and other surfaces. A special transfer sheet, usually ISO A4 size, is printed on a regular inkjet printer. Our silicone baby products were printed by inkjet transfer printing.

heat transfer printing service

JUTION provides professional thermal transfer printing services. We can perform heat transfer printing of logos and patterns on various silicone products according to user needs.

If you need small batches of custom-designed products and require full-color patterns or logos, we recommend using heat transfer printing services. Connect with Jution Silicone Today to Enhance Your Brand’s Visibility with Custom Silicone products by heat transfer printing decoration.

Advantages and Disadvantages of Heat Transfer Printing

The advantages of heat transfer printing include:

- The ability to produce high-quality, full-color prints

- The ability to print on a wide range of substrates

- The ability to produce small runs and custom designs

- Cost-effective for smaller orders

The disadvantages of heat transfer printing include:

- Limited durability

- Limited color accuracy

- Limited washability

- Limited stretchability

How to Produce Safe Heat Transfer Printing on Baby Silicone?

Food‑grade silicone molding:Use the compression molding, LSR molding or Dripping molding with the Food grade materil to molded the Food grade silicone baby products firstly.

heat press materials and Thermal printing on silicone:

Heat transfer printing can be used on silicone surfaces to create designs, patterns, or logos.

In your quest to achieve the perfect silicone transfer print, it is important to keep a few things in mind. Here is a list of some of the best practices that you can follow for optimal success:

Use Precision Transfer Pads: Lastly, only go with transfer pads that match the design size and shape. This ensures that contact with the substrate can be optimized. Also, only select pads with appropriate hardness and flexibility for accurate transfers.

Surface treatment and ink compatibility are the most critical steps for long‑term durability.

Then you need put the printing finished silicone baby products do the Secondary curing and stabilization Safety and durability testing to make sure all the silicone baby products in good quality.

Thermal printing on fabric

A heat press enables you to transfer graphics, logos, artwork, etc. onto an item of your choosing. The item you are printing on is called your substrate and is oftentimes apparel or other soft goods.

thermal transfer printing on plastic

Thermal transfer printing is the latest technology perfectly suited for printing on plastic products

Applications of Heat Transfer Printing in Different Industries

Heat transfer printing has various applications in different industries, including fashion, sports, home décor, and marketing. It is used to create custom t-shirts, jerseys, hats, bags, and silicone products.

Best Applications for Silicone Heat Transfer:

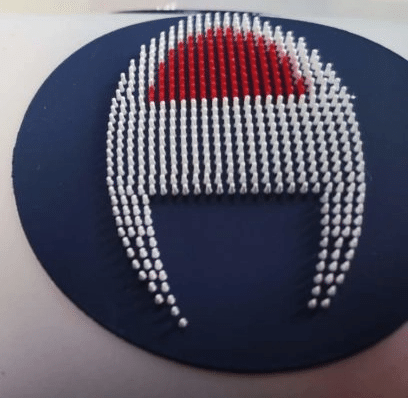

Silicone Wristbands:

Heat transfer printing can achieve highly consistent multi-color patterns while maintaining the soft feel of the bracelet. Compared to single-color screen printing, heat transfer printing has significant advantages in color gradation and batch stability.

Silicone wristbands are one of the most mature and typical products for heat transfer printing, especially suitable for:

Mass production (thousands to hundreds of thousands of pieces)

Multi-color logos, gradient colors, or complex text

Brand promotion, event commemoration, and charitable projects

Silicone Swim Caps:

Silicone swim caps are frequently stretched during use, requiring extremely high crack resistance in the printed layer.

With proper surface treatment and ink system, heat transfer patterns can remain intact after repeated stretching, without easily cracking or peeling. This is a key reason why many swim cap brands choose heat transfer over ordinary screen printing and UV printing.

Silicone Baby Products:

In baby and toddler silicone products (such as baby bath products, bibs, and placemats), the core prerequisite for heat transfer printing is safety and compliance.

Applicable prerequisites include:

Using inks that comply with FDA/LFGB requirements

Strictly distinguishing between chewable and decorative areas

Not affecting the food contact safety of the silicone itself

In areas not directly in contact with the mouth, heat transfer printing can be used to enhance product friendliness and brand recognition.

Silicone Kitchenware:

Silicone kitchen utensils (such as baking mats, spatulas, and cutlery) require extremely high heat resistance.

With proper processing, heat transfer patterns can withstand dishwasher cleaning and daily baking use, and are not easily peeled off due to high temperatures or repeated washing. However, it is important to note that the pattern should be placed away from areas that will be exposed to direct heat for extended periods.

Choosing the Right Substrate for Heat Transfer Printing

The substrate is the surface that the design will be transferred onto, and it is essential to choose the right one for heat transfer printing. The substrate should be smooth, flat, and clean to ensure that the design transfers correctly. Some common substrates for heat transfer printing include cotton, polyester, and silicone.

Equipment and Materials Required for Heat Transfer Printing

To do heat transfer printing, you will need the following equipment and materials:

- Transfer paper

- Heat transfer vinyl or ink

- Heat press

- Substrate (e.g., silicone baby bib)

Why Heat Transfer Printing Matters in Baby Silicone Products?

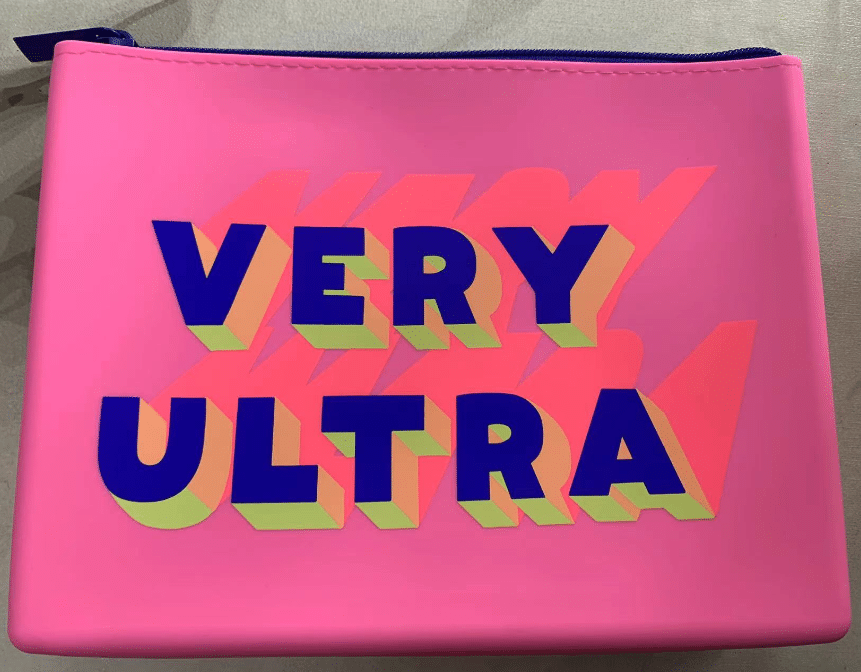

In the global baby products market, visual design increasingly influences purchasing decisions. Parents associate friendly patterns, soft colors, and recognizable characters with emotional safety and brand trust. For silicone baby products, heat transfer printing enables:

Complex cartoon and IP‑based designs

Consistent multi‑color patterns,fading pattern

Fine lines that cannot be achieved by molding alone

But baby silicone products are exposed to chewing, saliva, washing, and repeated handling, making printing technology selection critical.

Who Should Use Heat Transfer Printing for Baby Silicone Products?

Heat transfer printing is suitable for:

The Brand Owner / Product Manager who would like to Baby brands developing premium or mid‑range products

The Industrial Designer, Purchasing Manager / Sourcing Manager,OEM/ODM Clients Who would like to develop IP‑licensed baby product projects

The Cross-border E-commerce Brand Products where visual identity supports brand differentiation

It is not recommended for:

Ultra‑low‑cost baby products

Constant high‑temperature sterilization environments

Direct chewing zones on teethers or pacifiers or eating food directly contact area.

When to Plan Heat Transfer Printing in silicone Product Development?

The correct time to plan heat transfer printing is during the industrial design (ID) and material confirmation stage. Early planning allows:

Separation of chewing vs non‑chewing zones

Optimization of surface texture for ink adhesion

Avoidance of late‑stage design compromises

Adding heat transfer printing after mold finalization significantly increases quality risk.

Where Heat Transfer Printing Is Commonly Used in Baby Silicone Products?

Silicone baby bibs ,Silicone placemats and silicone mats,Outer surfaces of suction bowls and plates,Non‑contact food decorative areas on storage lids,Direct oral contact areas ,We suggest remain unprinted or molded‑color only.

How Much Does Heat Transfer Printing Cost for Baby Silicone Products?

The price include:

Transfer film preparation need a jig and film cost

Ink formulation suitable for silicone

Additional labor and curing steps

Testing and compliance validation

Lower prices often indicate compromises in ink grade, curing time, or testing coverage, which increases long‑term recall and complaint risk.

How to Choose a Supplier for Baby Silicone Heat Transfer Printing?

1.Has the supplier produced baby silicone products at scale?

2.Are inks tested for food‑contact safety?Does they can offer the cerfication for the inks

3.Can durability testing data be provided? such as Abrasion resistance test report

4.Is printing avoided in chewing zones by design?

How are color consistency and batch control managed?

The Great Suppliers experienced in baby products focus on risk prevention, not just appearance.

How to Control silicone baby printing Quality During Mass Production?

- Control Color consistency monitoring

- Check the pattern Stretch and adhesion testing.

- Saliva and alcohol resistance simulation

- Batch traceability for transfer films.

The heat transfer printing silicone baby products quality control should simulate real baby usage conditions, not just visual inspection.

When you have the problem of heat transfer printing Pattern peeling,Hard surface feel like plastic label, Color fading problem, you may can contact Jution expert to offer your suggestion: update Surface activation treatment,change to correct Silicone‑specific ink.Process parameter optimization for heat transfer printing etc.

Tips for Achieving High-Quality Heat Transfer Prints

Why Heat Transfer Printing Matters in Baby Silicone Products

To achieve high-quality heat transfer prints, follow these tips:

- Choose high-quality transfer paper and ink: Using high-quality transfer paper and ink will ensure that your prints look great and last longer.

- Prepare the substrate properly: Make sure the substrate is clean, dry, and free of wrinkles before applying the transfer.

- Use the right settings on the heat press: Make sure the heat press is set to the right temperature, time, and pressure for the type of transfer paper and substrate you are using.

- Apply even pressure: Apply even pressure across the entire design to ensure that the transfer is smooth and free of wrinkles.

- Peel the transfer paper carefully: Allow the transfer to cool down before peeling off the transfer paper, and peel it slowly and carefully to avoid damaging the print.

Heat transfer printing vs silicone screen printing

For complex, multi-colored patterns, heat transfer printing is the preferred option; for simple, single-color logos, screen printing can be chosen.

| Comparison | Heat transfer printing | Silicone screen printing |

| Color complexity | High, suitable for multiple colors and gradients | Low, suitable for monochrome or few colors |

| Batch consistency | High | Relying on artificial stability |

| Cost structure | The initial plate-making cost is relatively high. | Smaller batches have an advantage. |

| Durability | Depends on surface treatment and ink | Mature and stable |

Is Direct to Film (DTF) suitable for silicone?

DTF transfers (silicone DTF transfers) have become a popular search term in recent years, but it’s important to clarify the following:

Standard DTF processes are primarily suitable for textiles.

Direct application to pure silicone surfaces poses significant risks to adhesion and durability.

Some modified DTF solutions can be applied to silicone after special treatment, but their long-term stability still requires careful evaluation. In infant or food contact products, it is generally not the preferred solution.

Can you sublimate on silicone?

Pure silicone materials typically cannot be directly sublimation printed.

This is because silicone itself lacks the structure to absorb sublimation ink. To achieve a similar effect, it is usually necessary to:

add a special coating to the silicone surface

or use a heat transfer process to transfer the pattern

This is why, in the silicone product industry, heat transfer remains a more controllable and mature solution.

Frequently Asked Questions about Heat Transfer Printing

Is heat transfer printing safe for baby silicone products?

Yes, when applied to appropriate areas using compliant inks and controlled processes.

Can heat transfer printing be used on teething areas?

It is not recommended for direct chewing zones.

How to Clean Baby Silicone Products with Heat Transfer Printing?

Recommended cleaning:Warm water with mild detergent by hand clean,Soft sponge or cloth.

Avoid:Abrasive scrubbers,Strong alkaline cleaners,Prolonged high‑temperature boiling

The Proper care preserves both safety and appearance.

Conclusion

Heat transfer printing is a versatile and cost-effective printing method that can be used to create high-quality, full-color prints on various substrates, including silicone baby products. With the right equipment, materials, and techniques, you can create beautiful and long-lasting designs that are sure to impress.For baby silicone products, success depends on location control, material compatibility, and process discipline. Follow our tips and FAQs to get the most out of your heat transfer printing projects.

Choosing experienced suppliers and integrating printing decisions early in product development significantly reduces quality and safety risks.Contact Jution silicone expert to begin your heat tranfer printing silicone baby product journey