What is the Difference Between Natural Rubber and Silicone?

When it comes to choosing materials for various applications, natural rubber and silicone are two popular options that often come to mind. Both materials have unique properties, making them suitable for a wide range of uses, from baby products and kitchen utensils to medical equipment and automotive parts.

In this comprehensive comparison, we’ll explore the differences between natural rubber and silicone, discussing their properties, advantages, and limitations to help you better understand which material is best suited for your specific needs and applications.

Natural Rubber Properties

Natural rubber is derived from the latex of the rubber tree (Hevea brasiliensis) and has been utilized for centuries due to its unique properties. Key properties of natural rubber include elasticity, tear resistance, and abrasion resistance, which make it suitable for various applications.

The typical properties of natural rubber

| Property | Value |

|---|---|

| Tensile Strength | 17-24 MPa (megapascals) |

| Elongation at Break | 500-700% |

| Tear Strength | 40-60 N/mm (newtons per millimeter) |

| Hardness | 40-60 Shore A |

| Temperature Resistance | -60°C to 80°C (-76°F to 176°F) |

Advantages of natural rubber

- Biodegradability: Natural rubber is an eco-friendly material that decomposes over time, reducing its environmental impact compared to synthetic materials.

- Wide range of applications: Thanks to its elasticity and durability, natural rubber can be used in various industries, such as automotive, construction, and consumer products.

- Cost-effectiveness: Natural rubber is generally more affordable than silicone, making it a budget-friendly option for many applications.

Limitations and Concerns

Despite its numerous advantages, natural rubber has certain limitations and concerns that are essential to consider when choosing the right material for your specific application:

- Allergenic potential: Some people may be allergic to natural rubber latex, which can cause skin irritation or more severe allergic reactions. This factor is particularly important to consider when using natural rubber in medical and healthcare applications or baby products.

- Sensitivity to heat and UV exposure: Natural rubber tends to degrade when exposed to high temperatures or prolonged sunlight. This can lead to a loss of elasticity and strength, limiting its suitability for outdoor applications or environments with extreme temperature variations.

- Limited chemical resistance: Natural rubber has a lower resistance to oils, solvents, and certain chemicals compared to silicone. This can limit its use in applications where contact with such substances is common, such as automotive components and industrial seals.

Understanding the limitations and concerns of natural rubber can help you determine if it’s the appropriate material for your application, or if an alternative like silicone might be a better choice.

Silicone Properties

Silicone is a synthetic material made from silicon, oxygen, carbon, and hydrogen, offering a unique combination of properties that make it suitable for a wide range of applications. Key properties of silicone include temperature resistance, chemical resistance, and hypoallergenic properties.

The typical properties of silicone

| Property | Value |

|---|---|

| Tensile Strength | 3-10 MPa (megapascals) |

| Elongation at Break | 200-800% |

| Tear Strength | 9-55 N/mm (newtons per millimeter) |

| Hardness | 20-80 Shore A |

| Temperature Resistance | -60°C to 230°C (-76°F to 446°F) |

Advantages of silicone

- Versatility in various applications: Silicone’s unique properties make it ideal for use in a wide range of industries, such as healthcare, automotive, electronics, and food services.

- Durability and long-lasting performance: Silicone is resistant to wear and tear, and its excellent temperature and chemical resistance contribute to its durability.

- Easy maintenance and cleaning: Silicone is resistant to staining and can be easily cleaned, making it a popular choice for kitchen utensils, baby products, and medical devices.

Similar to natural rubber, it’s crucial to consider the specific requirements of your application when determining if silicone is the most suitable material for your needs.

Limitations and Concerns

While silicone offers several advantages, it’s important to be aware of its limitations and concerns when selecting the right material for your application:

- Environmental impact: Unlike natural rubber, silicone is not biodegradable and can take a long time to break down in the environment. This factor should be considered when looking for an eco-friendly material option.

- Higher initial cost: Silicone materials can be more expensive than natural rubber, which may be a concern for budget-conscious applications or projects.

- Lower tear resistance compared to natural rubber: Although silicone is a durable material, it generally has a lower tear resistance than natural rubber. This can make it less suitable for applications requiring high tear strength.

Comparing Natural Rubber and Silicone in Various Applications

When choosing between natural rubber and silicone, it’s essential to evaluate their suitability for specific applications:

Baby products (bibs, pacifiers, and toys): Silicone is often preferred for its hypoallergenic properties and ease of cleaning. Carefully consider the needs of the baby and any potential allergies when making your choice.

Custom Silicone Baby Bibs

Custom Silicone Baby Toys

Kitchen utensils and bakeware: Silicone’s high-temperature resistance and ease of cleaning make it a popular choice for kitchen applications. However, natural rubber can also be used for certain items, such as spatulas and oven mitts, where its elasticity and lower cost may be advantageous.

Medical and healthcare products: Silicone’s hypoallergenic properties and resistance to sterilization make it ideal for medical applications. However, natural rubber can still be used for certain products, such as tourniquets and gloves, where its elasticity is beneficial.

Automotive and industrial applications: Both materials have their place in automotive and industrial applications, with silicone being preferred for high-temperature environments or those requiring chemical resistance, and natural rubber being favored for its cost-effectiveness, elasticity, and durability.

Conclusion

Understanding the key differences between natural rubber and silicone can help you select the right material based on your specific needs and applications. By carefully considering the advantages and limitations of each material, you can make an informed decision that takes into account factors such as cost, durability, eco-friendliness, and potential allergenic concerns. Ultimately, the choice between natural rubber and silicone will depend on the unique requirements of your project or product.

Related Blog

-

which is better silicone or rubber

which is better silicone or rubber What is silicone? Silicone is a kind of highly active adsorption material, belonging to the amorphous substance, insoluble in water and any solvent, non-toxic and tasteless. Silicone has many unique physical and chemical properties, it has high adsorption, good thermal and chemical stability, and high mechanical strength. These properties

-

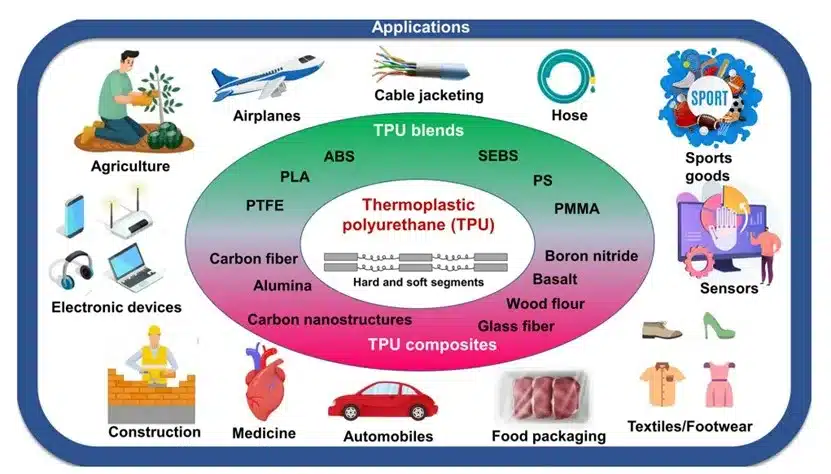

TPU(Thermoplastic Polyurethane)and Silicone

TPU(Thermoplastic Polyurethane)and Silicone What is TPU? TPU is an (AB) N-type block linear polymer made of polyester or polyether, where part A is a high molecular weight polyester or polyether, and part B is a diol containing 2-12 straight chain carbon atoms, linked by a diisocyanate. TPU is transparent and suitable for applications that require

-

The safety and cleaning methods of silicone baby toys

The safety and cleaning methods of silicone baby toys As a professional who has been deeply involved in the field of silicone materials for many years, I am well aware of the importance of safety and cleanliness of infant and toddler products. Due to its unique diversity, silicone baby toys have become an ideal choice

-

The diversity of silicone toys Stimulating babies’ desire for exploration

The diversity of silicone toys Stimulating babies’ desire for exploration As a professional with many years of experience in the field of silicone materials, I have witnessed how silicone materials have reshaped the landscape of maternal and infant products with their unparalleled safety and functionality. During the critical period of a baby’s growth, appropriate sensory

-

The difference between silicone and rubber

The difference between silicone and rubber What is silicone? silicone is a kind of highly active adsorption material, belonging to the amorphous substance, insoluble in water and any solvent, non-toxic and tasteless, chemically stable, and does not react with any substance except strong alkali and hydrofluoric acid. Due to its chemical composition and physical structure,