Project details

Project Difficulties

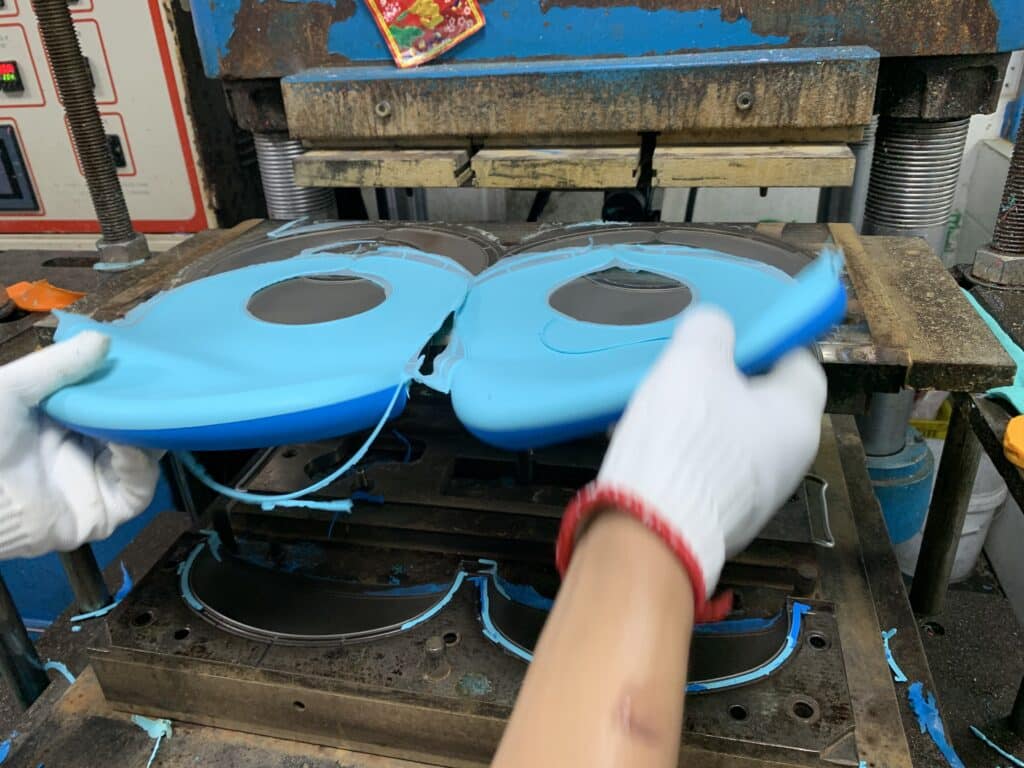

Dual-color molding issue: Standard silicone production methods struggled to achieve seamless two-color integration.

Printing durability: Heat transfer printing often resulted in fading or peeling after washing. We have more than 6 customers who have used heat transfer bibs and have encountered this problem. Finally, they were all solved with the help of our engineers.

High precision & safety standards: As a baby product, it had to meet strict international safety certifications (FDA, LFGB, EN71).

Solution

Technical Innovation: Instead of conventional shrinkage methods, our team explored an alternative molding approach.

Continuous Trials: We created 4 different molds and ran multiple experiments, consuming over 1 ton of silicone material.

Collaborative Problem-Solving: Despite high costs in materials and manpower, we remained committed to the original contract—only charging the client for one mold fee.

Successfully delivered a perfect dual-color silicone bib that met the brand’s visual, functional, and safety requirements.

Related Product

Further Reading:

How To Make Silicone Bibs?

How to Print Logo or Pattern on Silicone Bibs?

Client Feedback

Finally, after 9 months of hard work in developing the new project, we delivered 10,000 products within the specified time during the bulk order period. The customer expressed satisfaction after inspection and use and replied to us:

Other Projects

No posts