TPU(Thermoplastic Polyurethane)and Silicone

What is TPU?

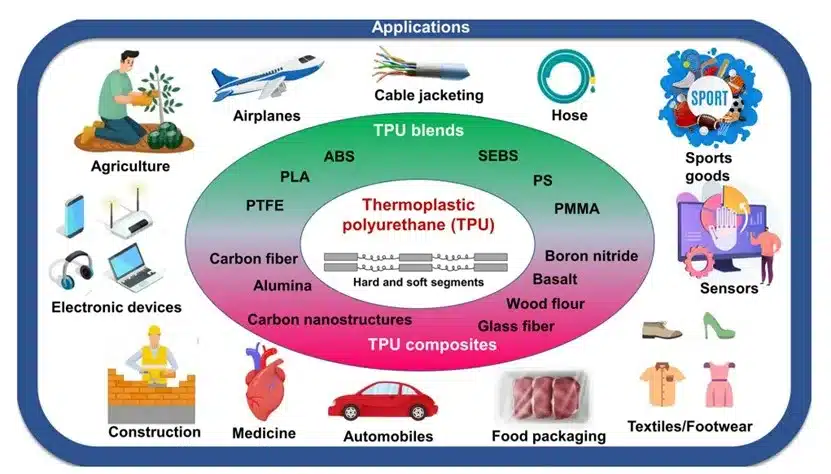

TPU is an (AB) N-type block linear polymer made of polyester or polyether, where part A is a high molecular weight polyester or polyether, and part B is a diol containing 2-12 straight chain carbon atoms, linked by a diisocyanate.

TPU is transparent and suitable for applications that require transparency, it has a good elastic hardness range and is very wear-resistant.

TPU is widely used in many fields because of its excellent performance.

What is silicone?

Silicone is a kind of highly active adsorption material, belongs to the amorphous substance, has good thermal stability and chemical stability.

Silicone is insoluble in water and any solvent, non-toxic and tasteless, chemically stable, and does not react with any substance except strong alkali and hydrofluoric acid.

How are TPU and silicone processed?

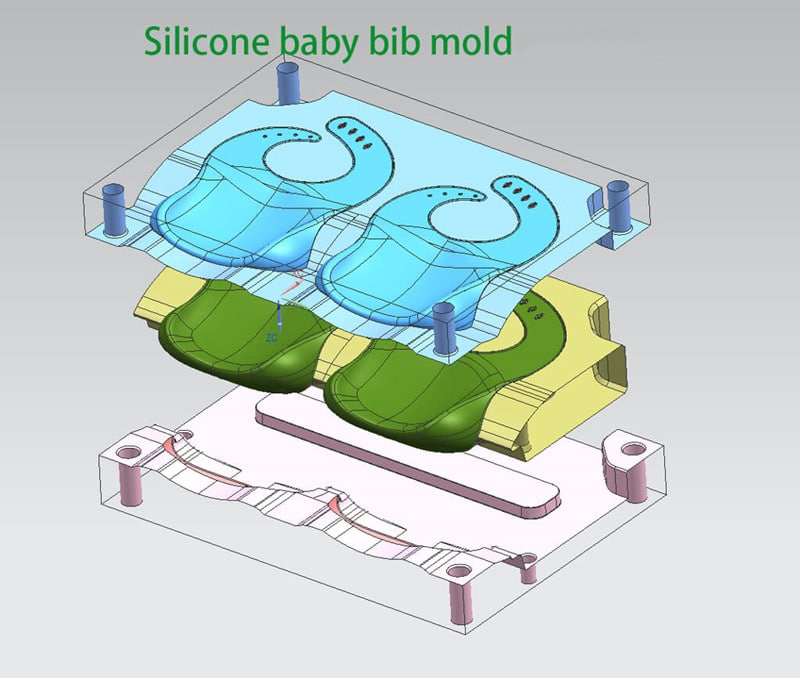

Silicone is made in a very special way. They include extrusion molding, die molding and cutting molding. To some extent, the same method can be used to produce TPU components.

Processing TPU is more challenging than silicone. One reason for this is the polymer class of each material. Thermosetting plastics and thermoplastics have completely different properties and behaviors at high temperatures. Thermoset plastics cannot be melted, while thermoplastics decompose easily when exposed to heat.

Where is the application of TPU?

Where is the application of silicone?

The applications of silicone are quite niche and particular. These are applications that have been carefully chosen after gathering a lot of information about the use cases.

Electronic and electrical appliances: silicone is used for dry mildew proof packaging of electronic and electrical appliances to protect precision optical instruments and electronic equipment from moisture damage.

automobile manufacturing: silicone is used for sealing and protection of auto parts to improve the safety and durability of vehicles.

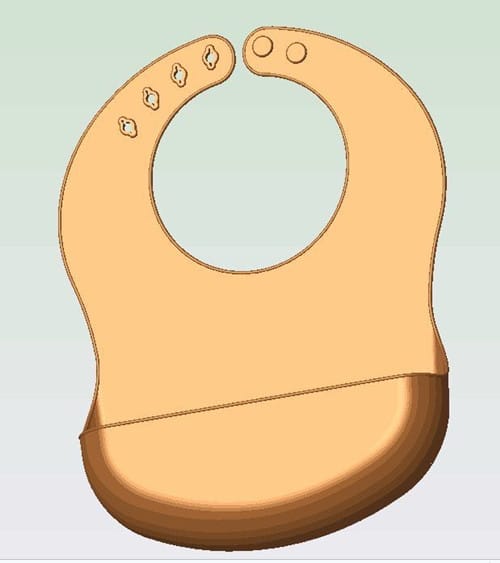

Household articles: silicone products such as silicone spoons, silicone bowls, silicone dinner plates, etc., are widely used in baby care and home cooking .

kitchen supplies: silicone cutting board, cleaning gloves, non-slip mat, etc., to provide convenient and safe kitchen operation experience.

When is it appropriate to use silicone?

High safety requirements: In the field of food contact and medical use, there are extremely high standards for the hygiene and biosafety of materials, and silicone is a high-quality material to meet these requirements.

Working in extreme temperature environment: silicone with its unique chemical structure, has excellent high temperature resistance, low temperature resistance, maintain good elasticity and sealing performance, when the product faces the test of extreme temperature environment, silicone is a very ideal material choice.

When is it appropriate to use TPU?

Material wear resistance and mechanical properties requirements are high: TPU because of its unique molecular structure gives it excellent wear resistance and mechanical properties, its wear degree is much higher than many traditional materials, and it can still maintain its shape and properties after multiple bending and stretching.

Need rapid prototyping and processing projects: TPU has good rapid prototyping and processing characteristics, it can be rapid prototyping through injection molding, extrusion, blow molding and other molding processes, greatly shortening the production cycle of the product.

Who are the main users of silicone?

Medical equipment manufacturers: The biocompatibility and high and low temperature resistance of silica gel make it have a wide range of applications in the medical field, such as the manufacturing of medical equipment, medical catheters, etc.

Food processors: suitable for high-grade food mold mold, chocolate mold, candy mold, cake mold, and high-grade simulation ingredients food grade silicone mold production is also suitable for food grade process decoration, food sugar art model, silicone pacifier and high temperature baking silicone rubber products applications.

Who are the main users of TUP?

Clothing designer: TPU applications in the clothing industry include the production of shoe materials, watchbands, mobile phone protective cases, etc., because of its high bond strength, soft and elastic, heat and water resistance advantages, and will not release formaldehyde, in line with safety standards.

Electronic appliance manufacturers: TPU is often used to make mobile phone cases, tablet computer protective cases, etc., because it has good weather resistance and wear resistance.

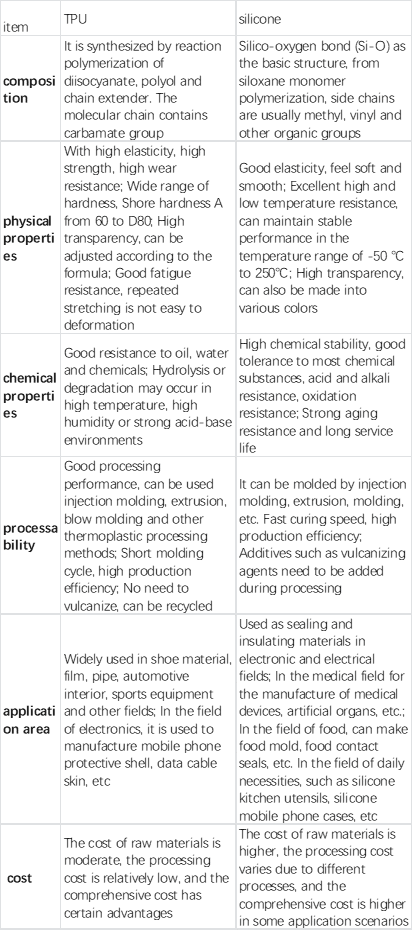

How much does the cost of TPU and silicone need?

The raw material cost of silicone is relatively high, and despite the high cost, the durability of silicone and its adaptability to extreme environments make it potentially more cost-effective over the course of long-term use.

The initial cost of TPU may be relatively low, their processing is relatively simple, they perform well in a variety of manufacturing processes, and they are suitable for mass production.

Conclusion

TPU and silicone each have their own unique characteristics and advantages, and the choice of which material should be based on the specific application scenario and product needs. In the field of manufacturing, TPU is a good choice for products with high elasticity and wear resistance requirements; In high temperature environments, where hardness and insulation properties are strictly required, silicone may be more suitable. The final choice should consider product characteristics, cost, processing technology and other factors to meet the specific needs of the product.

Would you like to create your silicone products brand or look for reliable and safe silicone baby products with your logo for your Event? Jution silicone can help. Get an online quote with free design from Jution for quality silicone baby products within days.