How To Make Silicone Bibs?

What are the Silicone baby Bibs?

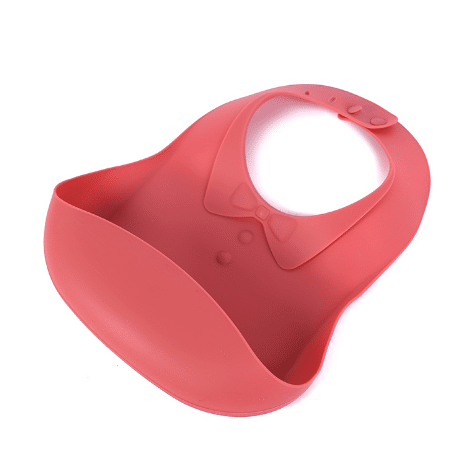

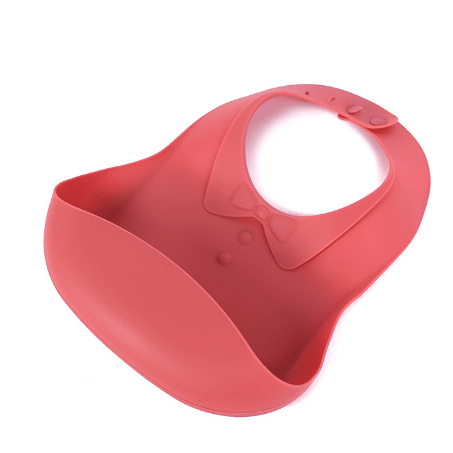

The silicone bib is made of 100% food-grade silicone. It is designed and attractive according to the needs of babies. It is suitable for infants over 3 months old or the elderly. It belongs to the silicone baby category among silicone products.

Silicone bibs are safe,BPA, PVC and phthalate-free,Lead free,convenient waterproof and easy cleaning, and hygienic baby products, specially designed to prevent baby saliva or food from falling, and keep clothes and floors clean.

Silicone bibs mainly made of silicone material, which is soft, non-toxic, and high temperature resistant. It is usually made of food-grade silicone, which has a gentle touch and will not cause allergies or discomfort even if it comes into contact with the baby’s delicate skin for a long time. Silicone bibs are designed to protect the baby’s clothes and skin from being contaminated by food or liquids when eating or playing.

The silicone bibs are easy to wash, can be kept clean and hygienic, and have a certain durability, and can accompany the baby through multiple growth stages.

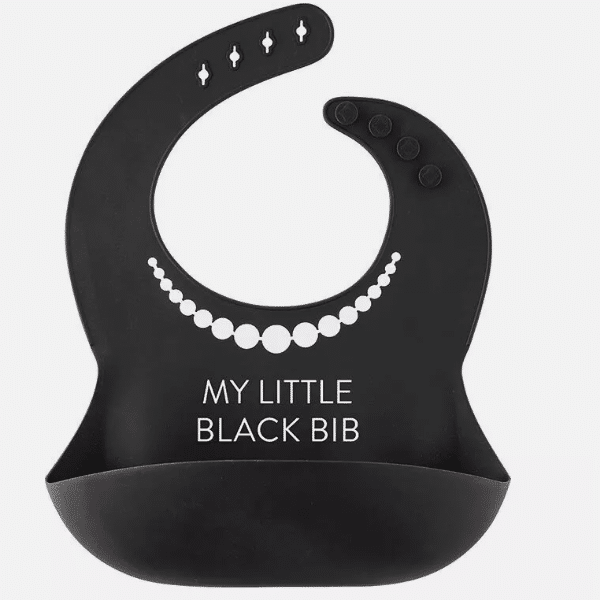

The appearance design of silicone bibs focuses on high-end texture and good performance. It is suitable for use in formal occasions such as family gatherings and festivals, adding a touch of elegance to the baby’s table manners. At the same time, there is no shortage of silicone bibs with novel designs and rich colors on the market, which can meet parents’ pursuit of personalization.

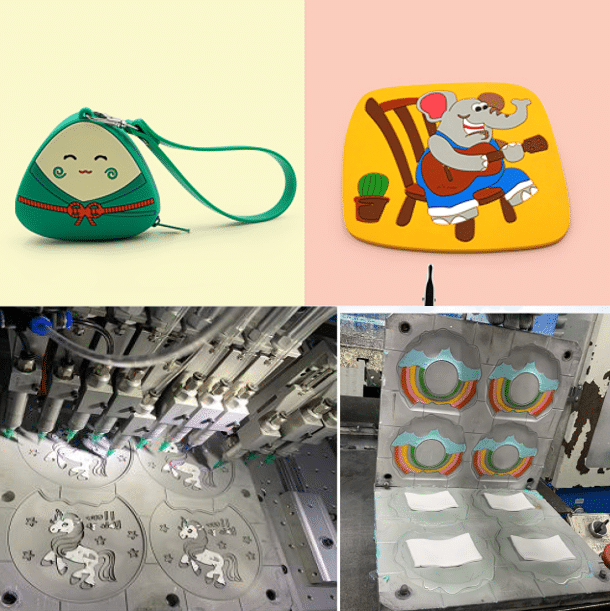

Custom Silicone Baby Bibs

The main features of the silicone bib include:

The design of the silicone bib lies in the combination of its shape and functionality, aiming to provide a practical and safe baby care solution.

How to make the silicone bibs?

1. Design 3D structure of the silicone bibs according to your idea

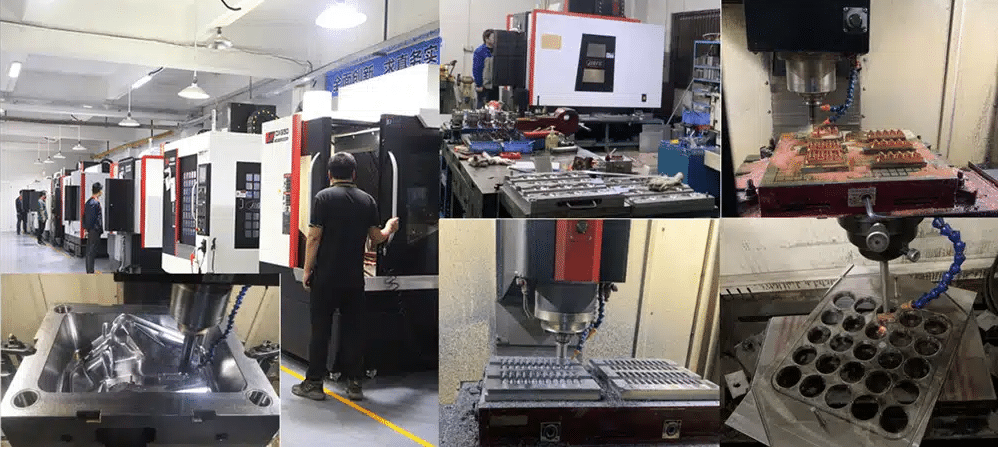

2. Make the silicone bibs tooling according to the silicone bibs design requirements (Signal color or multi color) use the different metal, such as steel, copper or AL to ensure the accuracy and durability of the tooling. Check the (Prototype and Mold Development Service) to know more about silicone tooling making process.

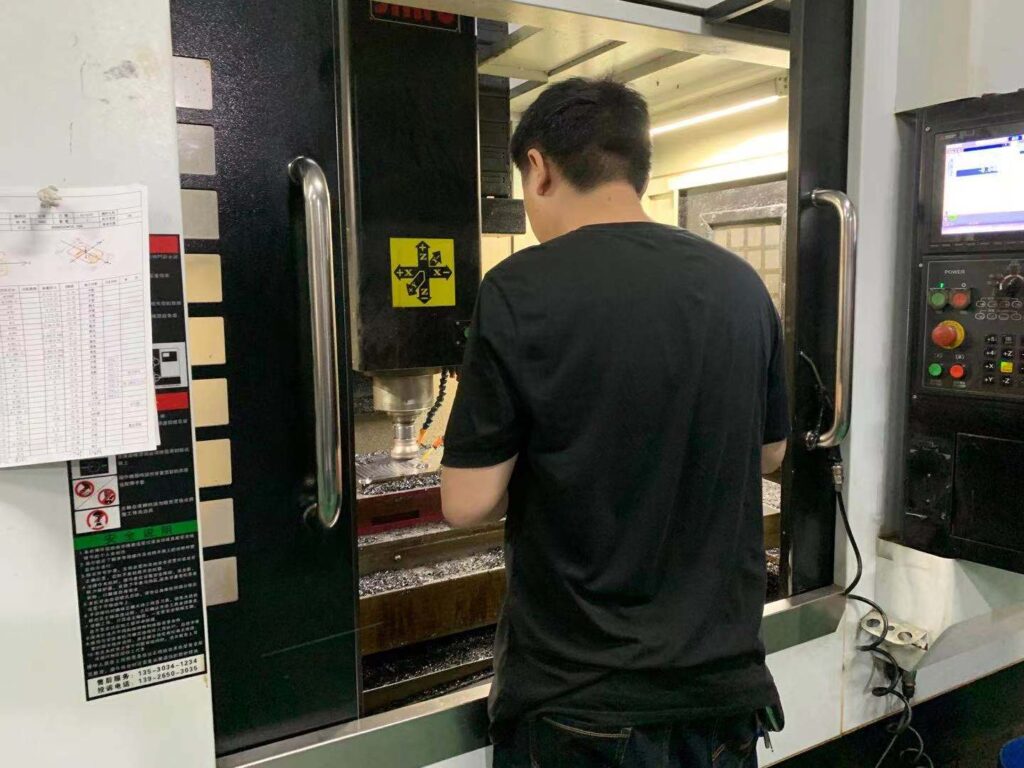

Jution Silicone & Rubber (Dongguan) Co., LTD ’s in-house tool shop consists of 21 latest state-of-the-art 3-axis CNC machines and 5 EDM machines. Our proprietary CNC milling and machining processes enable quick turnaround and beat your deadlines with our quick-turn CNC machining.

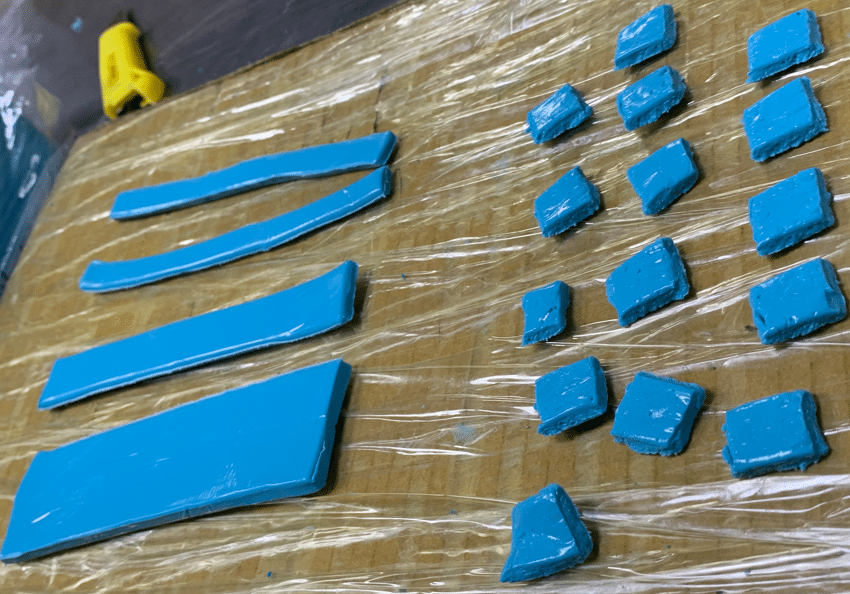

3. 3.Prepare the silicone raw material: Raw materials are the key to silicone maternal and infant products. Usually, infant products meet certain environmental protection standards, so silicone materials are no exception. Normally, environmentally friendly Fumed silicone rubber is selected for customized processing, while many manufacturers use Precipitated silicone rubber for processing. Although the product is not greatly affected, it is still different Fumed silicone rubber from in quality after a long time. Mix the silicone color according to your silicone bibs needed. Cutting the mixed silicone material in the correct weight.

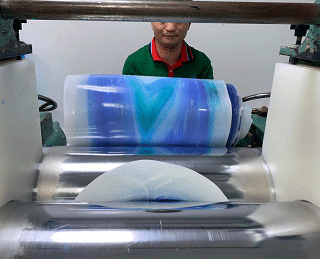

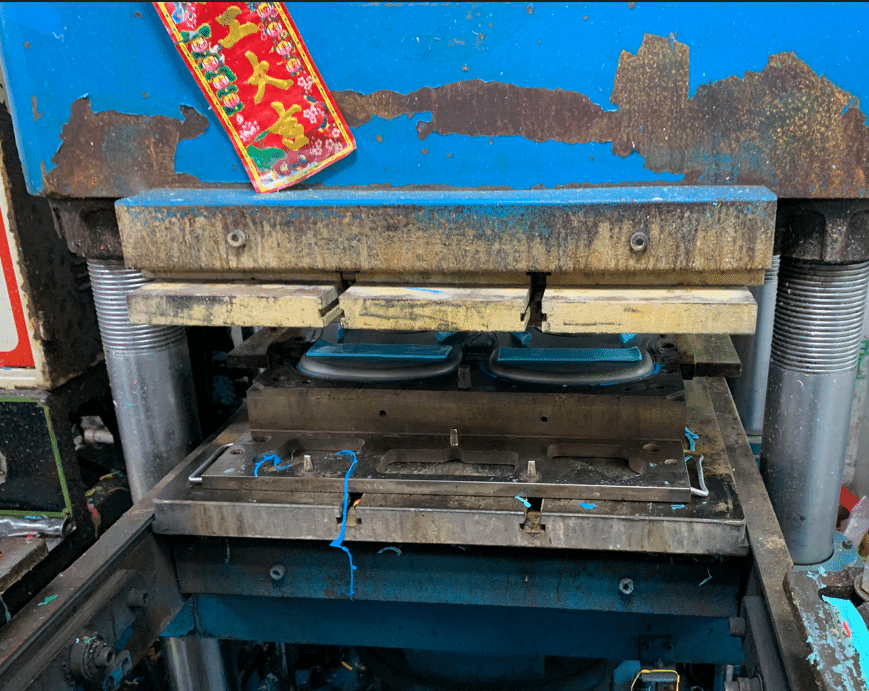

4. Feeding the prepared silicone mixed material on-no matter Liquid siilcone rubber or solid siilcone rubber in to the mold.

5. Curing the silicone bibs: The silicone material is feeding into the mold after mixing, and the silicone material is filled into the entire space of the mold through heating and pressure. The temperature, pressure and time control of the molding process directly affect the size, shape and quality of the product.

No matter the silicone baby bibs was made by: Compression molding or co-injection molding or LSR molding.

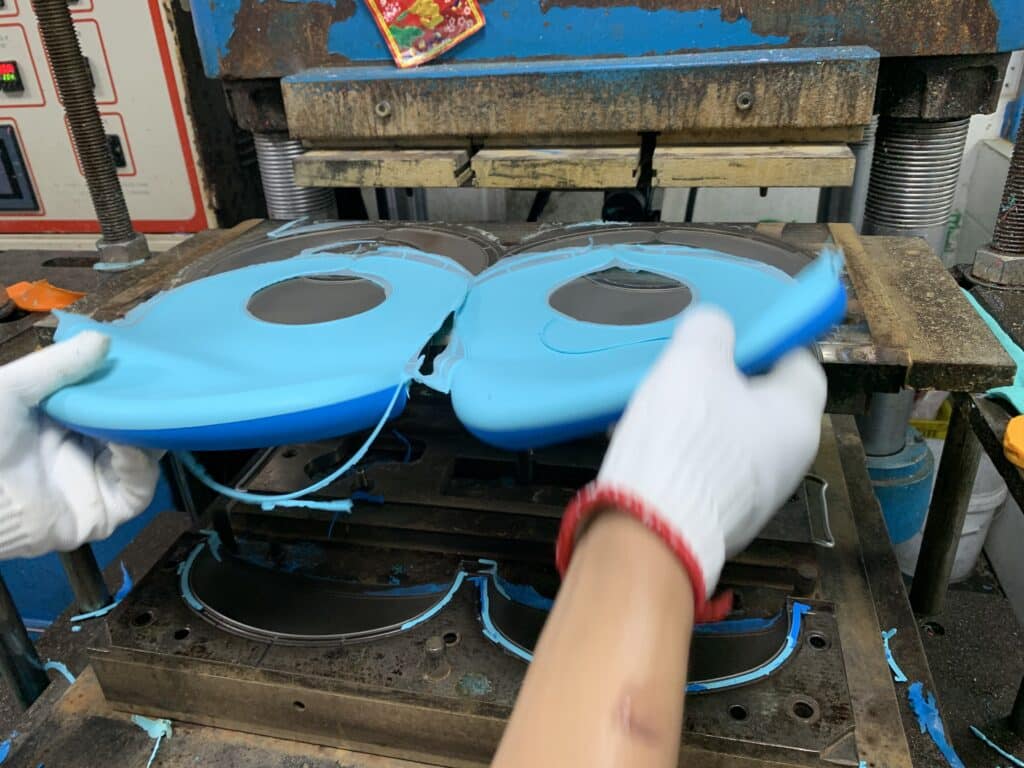

6. Demold: After the curing is completed, take the silicone bibs product out of the mold.

7. QC the silicone bibs: Quality inspection: Visually inspect the molded silicone bibs to see if there is lack of material, uncooked Ness, or impurities

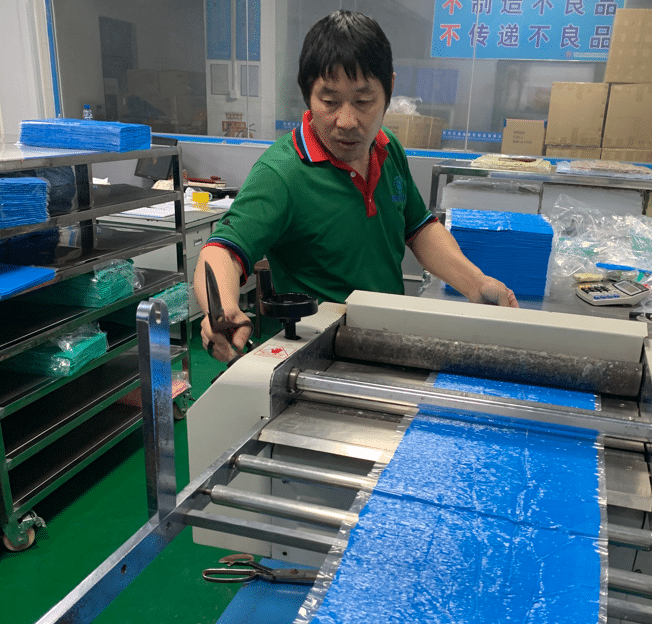

8. Post-processing: Carry out the silicone bibs and then do the post processing and treatment, such as trimming, grinding, polishing, spraying, inspection, etc.

9. Secondary vulcanization: Secondary vulcanization is a process that must be handled for any product that has passed the inspection. The main reason why infant silicone products have a certain smell is that they have not been subjected to Secondary vulcanization baking, and the catalyst of the raw materials of the products has not been emitted.

At present, many silicone children’s product manufacturers basically handle it, but the time and temperature of the Secondary vulcanization treatment are different. Bake in oven 2-4 hours to meet FDA or LFGB Standard. LSR silicone bibs may do not need this process.

10. LOGO or Pattern printing if needed: screen printing or laser engraving. Most of time, we put the silicone bibs logo on the silicone tooling directly. Check the products branding service to know more.

Silicone Baby Products Branding Service

11. Final Quality control and testing: After all the silicone bibs making process finished, we will arrange the final QC for the teether before the delivery. More information for the QC

Quality Control and Standards

12. Package and Warehouse: Jution silicone offer custom packaging solutions you need for all your product packaging. Our custom packaging includes paper boxes, PE/PVC boxes, printed labels, hangtags, barcode stickers, etc to protect the safety of the product during transportation and storage, while ensuring the safety and aesthetics of the product.

In Jution silicone, we manufacture the silicone bibs according to the client’s design and idea. We try our best to deliver the quality silicone bibs to our customer.

Why do you need to make the silicone baby Bibs?

When you need to create your own baby and children products brand for sales on the market. When you need to promotional your children and baby products with a promotion gift. You may can choice the cute bibs as a gift. When you need a souvenir for your upcoming event or get-together. The branded silicone bibs with added your logo, design pattern, text may be your good choices.

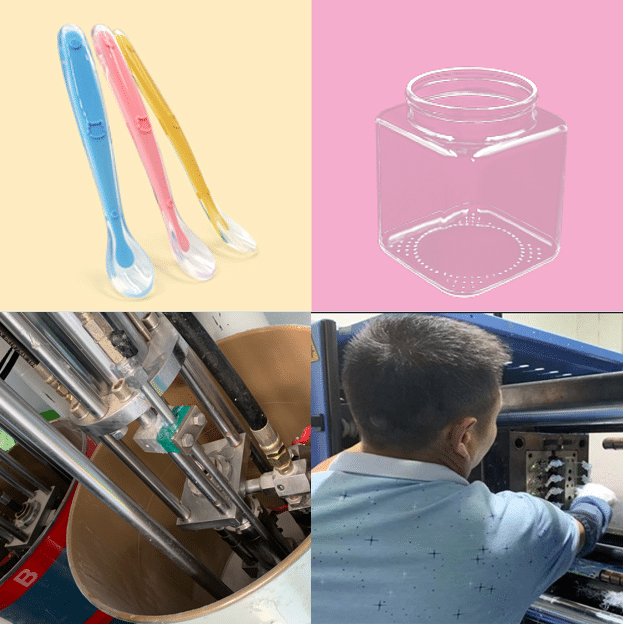

Usually, the silicone children’s products such as silicone bibs are made of solid silicone rubber and liquid silicone rubber.

The process is silicone compression molding and silicone dripping molding(multi-colors) or LSR molding.

Custom Silicone Compression Molding Service

Custom LSR(Liquid Silicone Rubber) Injection Molding Service

Silicone Dripping Dispensing Molding

The two process have different advantages and differences.

The solid silicone rubber bibs product cost is relatively low. The products produced can also reach environmentally friendly food grade, with high-quality materials, which is the choice of many consumers.

The liquid silicone processing is relatively high cost. It is processed with liquid silicone rubber with water-like materials. The Liquid silicone rubber bibs feels more softer, has better rebound, and the parting line is smaller than that of solid silicone. However, the minimum order of the silicone bibs is higher. And the LSR bibs injection mold cost is higher also.

When need the silicone bibs?

Silicone bibs are suitable for babies over 4 months, especially when babies begin to learn to eat independently, Silicone bibs become an indispensable choice.

The baby in eating learning and for anyone who tends to make a mess while eating. For the babies, should be from 3 months to 36 months. You need them.

Notice: When the parents buy the silicone bibs, should pay attention to

- With the Certification: IN USA -FDA Approved -CPSIA Compliant and California 65 BPA, lead, PVC-, and phthalates-free. Adjustable neck huge catch pocket Soft, Platinum food-grade silicone

- Design: Choose a silicone bib that is well designed and attractive for babies.

- Size: Choose the right size according to your baby’s age and body shape to ensure comfort and practicality.

- Brand Reputation: Choose a reputable brand that can provide better quality and after-sales service.

- Cleaning and Sterilization Methods: Learn how to clean and sterilize the silicone bib to ensure hygiene and safety.

- Storage Conditions: Learn how to store the silicone bib correctly to extend its life.

The advantage of silicone bibs?

The advantages of the silicone baby bibs are safety, convenience, hygiene, durability and easy washing, as well as soft and non-toxic food-grade silicone material.

Durable and easy to wash: The silicone material has good elasticity and flexibility, is not easy to break, and has a long service life. The surface of silicone is smooth and not easy to absorb dirt, which is easy to clean and maintain. It is easy to clean and can be restored to cleanliness with just a light wipe

Multifunctional design: The silicone bib is also available in a variety of styles and colors, which can be customized according to customer needs, suitable for infants and young children over 3 months old or the elderly. which helps to attract the attention of babies and increase their willingness to use the baby bibs. Its unique silicone belt design and bib-shaped bottom are used to catch dropped food and keep clothes clean. The silicone material can also withstand high-temperature disinfection, making it easy for parents to clean and disinfect the bib regularly.

Safety: Silicone baby bibs are usually made of 100% food-grade silicone, do not contain harmful substances, and meet food safety standards, which makes them a safe choice for children. silicone bibs are safe and non-toxic. They are BPA-free, PVC-free, lead-free, and phthalate-free,latex-free, Lead Cadmium, and Mercury -free, and non-toxic eco-friendly.

The silicone bib is suitable for contact with the skin and will not produce substances harmful to the human body, so it can be used with confidence. This material has passed the FDA and LFGB tests of SGS, proving its safety.

These advantages make silicone baby bibs is the good choice for parents when choosing tableware for their children. It not only ensures the safety of children’s food, but also facilitates parents’ cleaning work, and also promotes the development of children’s self-care ability.

Further Reading:

-

Silicone placemat and bib set, helping to cultivate your baby’s dining habits

-

silicone baby bib – Waterproof bib for babies when eatin

-

A comprehensive guide for selection and use silicone baby bib

-

Case Study: Two-tone Silicone Baby Bibs

-

High Performance Silicone Tableware For Baby

-

Top 10 China Silicone baby products Manufacturers and suppliers

How much of the silicone bibs?

From 1.29D-3.19USD/pcs depend on the design and structure and package

In Jution Silicone, we custom the silicone bibs (https://jutionsilicone.com/silicone-baby-feeding-manufacturer/custom-silicone-baby-bibs) shape, size, color, pattern and brands for your own silicone bibs, if you would like to custom your brands silicone bibs, contact jution.

Final Conclusion:

In Jution silicone, all the silicone bibs from raw material selection to molding, curing, and quality control, each step plays a vital role in creating silicone bibs that meet safety standards and perform well in their intended applications.

Understanding the silicone bibs manufacturing process is essential for sellers, allowing them to offer high-quality, safe products to their customers.

Contact Jution silicone to brand your own silicone bibs by contract manufacturing.

Related Blog

-

which is better silicone or rubber

which is better silicone or rubber What is silicone? Silicone is a kind of highly active adsorption material, belonging to the amorphous substance, insoluble in water and any solvent, non-toxic and tasteless. Silicone has many unique physical and chemical properties, it has high adsorption, good thermal and chemical stability, and high mechanical strength. These properties

-

What you need to know about silicone allergy

What you need to know about silicone allergy What is silicone allergy? Silicone allergy refers to the human body has an allergic reaction to silicone materials, this reaction is not common but it does exist. Silicone is a widely used in medical, industrial and other fields of material, under normal circumstances, qualified silicone products are

-

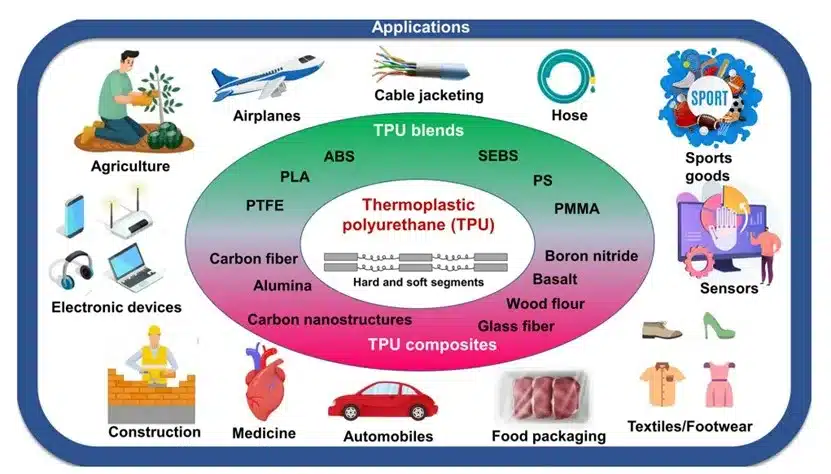

TPU(Thermoplastic Polyurethane)and Silicone

TPU(Thermoplastic Polyurethane)and Silicone What is TPU? TPU is an (AB) N-type block linear polymer made of polyester or polyether, where part A is a high molecular weight polyester or polyether, and part B is a diol containing 2-12 straight chain carbon atoms, linked by a diisocyanate. TPU is transparent and suitable for applications that require

-

The Silicone Toys for Kids and Adult -Pop-it

The Silicone Toys for Kids and Adult -Pop-it What is Pop-It silicone toy? Pop-It is a molded silicone toy that mimics the feeling of squeezing and has become a popular toy in elementary schools across the United States in recent years. The toy’s simple design allows users to experience the sensation of bouncing back by

-

The safety and cleaning methods of silicone baby toys

The safety and cleaning methods of silicone baby toys As a professional who has been deeply involved in the field of silicone materials for many years, I am well aware of the importance of safety and cleanliness of infant and toddler products. Due to its unique diversity, silicone baby toys have become an ideal choice