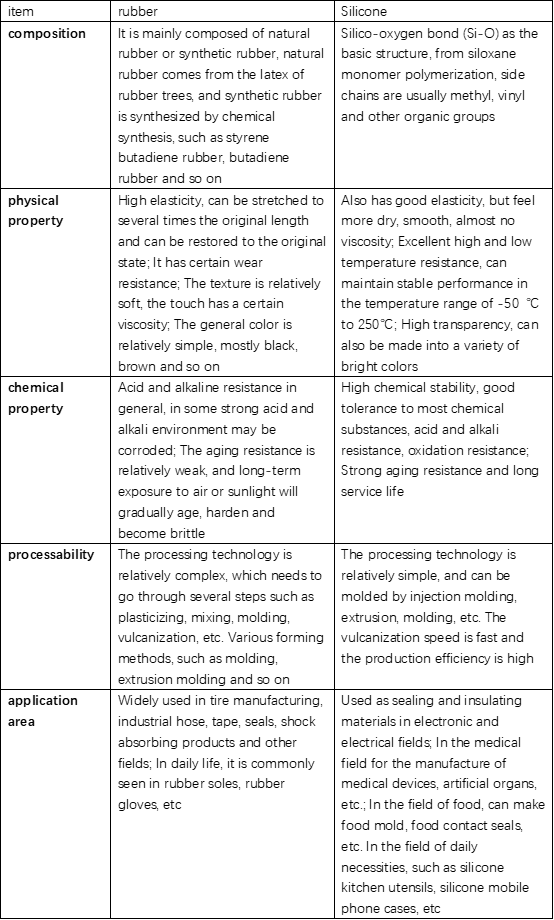

which is better silicone or rubber

What is silicone?

Silicone is a kind of highly active adsorption material, belonging to the amorphous substance, insoluble in water and any solvent, non-toxic and tasteless.

Silicone has many unique physical and chemical properties, it has high adsorption, good thermal and chemical stability, and high mechanical strength.

These properties of silicone make it widely used in many fields.

What is rubber?

Rubber is a polymer material with high elasticity, divided into natural rubber and synthetic rubber two kinds of rubber products, widely used in all aspects of industry and life. Rubber is elastic at room temperature, can produce large deformation under a small external force, and can be restored to its original state after external force removal.

Why does silicone have different properties?

The chemical composition and physical form of silicone can affect its properties: liquid silicone and ordinary silicone have significant differences in chemical properties and application fields. The application scenario of silicone will also affect its characteristics. For example, in medical devices, silicone needs to have good antibacterial, corrosion resistance and aseptic properties . The requirements of these application scenarios further affect the characteristics and performance of silicone.

Temperature resistance: Silicone has good temperature resistance, but organic silicone can be used in a wider temperature range, such as from -60°C to 200°C, and even higher.

Chemical resistance: organic silicone has good tolerance to a variety of chemical substances, and inorganic silica gel can resist the erosion of almost all chemical substances, showing better chemical stability.

Flame retardancy: organic silicone has certain flame retardancy, but the flame retardancy of different types of organic silicone varies greatly. Inorganic silicone has better flame retardancy, does not burn, and does not produce toxic gases.

Why does rubber have different properties?

Rubber has a variety of characteristics, mainly including high elasticity, viscoelasticity, electrical insulation, etc. These characteristics are mainly determined by its molecular structure and processing process.

High elasticity: The high elasticity of rubber is mainly due to its molecular structure and cross-linked networks. Rubber molecules are made up of many chains that can be cross-linked to each other through chemical reactions such as vulcanization, forming a cross-linked network. This network structure enables the rubber to quickly recover after external force, showing high elasticity.

Viscoelasticity: under the influence of temperature and time, rubber exhibits obvious stress relaxation and creep during deformation and recovery. This is because rubber molecules will deform when subjected to external forces, and gradually recover after removing external forces, this process is affected by time and temperature.

Electrical insulation: Rubber and plastic are electrical insulating materials, but due to different formulations, electrical insulation characteristics will be different. In addition, there are electrically conductive rubbers, which prevent electrification by reducing the insulation resistance.

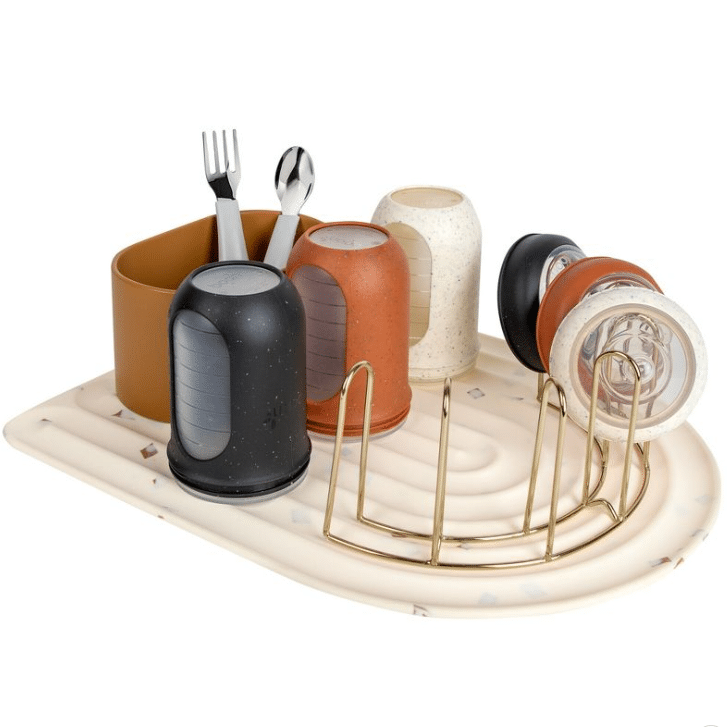

Where will silicone be used?

The diversity and versatility of silicone materials make it very widely used and become an indispensable part of modern life.

Jution silicone is a professional silicone baby products manufacturer in designing and manufacturing high-quality Custom silicone baby products in China for over 16 years experience. Jution silicone work with the baby products brands/wholesalers/ retails/distributors/Subscription boxes & gift sets/ corporate gifts promotional baby giveaways companies and offer a range of services from sketch to contract Manufacturing meet the unique needs of each silicone baby project.

Where will the rubber be used?

The application of rubber is almost in all fields, from daily life to industrial production, from military equipment to medical health, rubber can be seen.

When is it appropriate to use silicone and rubber?

Silicone and rubber each have different physical properties and applicable environments, so it is very important to choose the right material for different application scenarios.

Silicone has excellent high and low temperature resistance and is suitable for high temperature environment. Silicone has good elasticity and flexibility, as well as electrical insulation and UV resistance linearity, with a high degree of resistance, suitable for outdoor applications. Silicone is not affected by ultraviolet light or extreme temperatures and has a wider range of chemical resistance to chemicals.

Rubber is known for its excellent elasticity and flexibility and is suitable for use in situations where good elasticity and flexibility are required. Rubber has good wear resistance and impact resistance and is often used in the manufacture of products such as tires and shock absorbers. At room temperature, rubber has a high tensile strength and tear strength, suitable for high-wear industry applications.

How to use and process silicone and rubber?

The use and treatment of silicone: before using silicone, ensure that the working surface is clean, dry and free of oil; Prepare the necessary mixing tools and construction sites to ensure a clean environment; According to the proportion of product instructions, the silica gel and curing agent are fully mixed to ensure that the mixture is uniform without agglomeration; Apply the mixed silicone evenly on the parts that need to be bonded, and apply it as evenly and thinly as possible to avoid affecting the curing effect; After applying silica gel, wait for the curing time recommended by the product instructions. Keep the environment dry and avoid moisture during the curing process. The curing time is affected by environmental factors such as temperature and humidity.

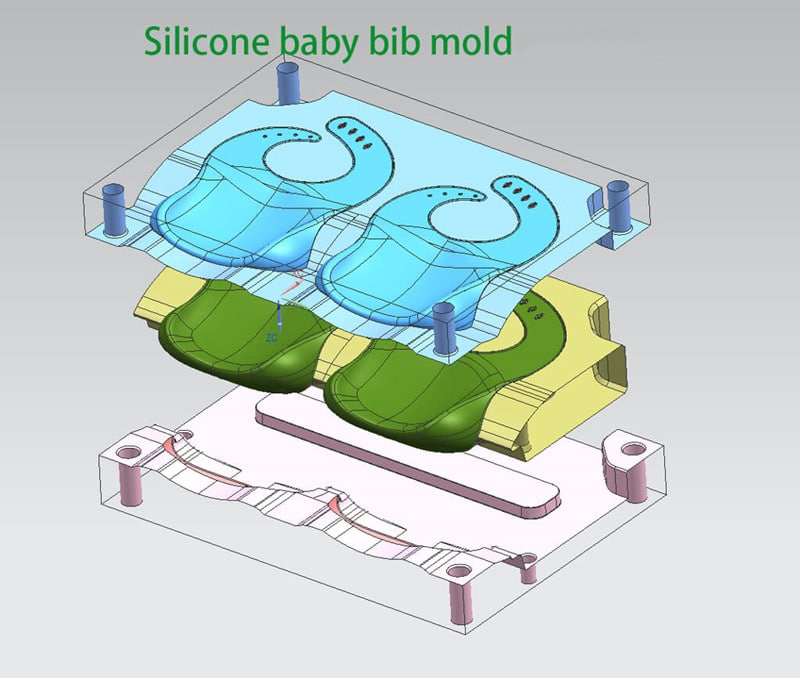

Rubber processing method: molding is the most common rubber processing method, through the shape of the mold to determine the shape of the product, usually need to add curing agent in the mold, through the vulcanization machine pressure and high temperature vulcanization molding; Extrusion molding is suitable for the manufacture of continuous strip or tubular products, rubber raw materials are heated in the extruder and molded through the mold; Calendering is suitable for the manufacture of simple sheet and plate-like products by pressing the mixed rubber into a film of a certain thickness and width through the calendering machine.

Which professionals will use silicone and rubber?

The professionals who use silicone are the production and maintenance of automotive parts automotive industry professionals, medical industry professionals, food processing industry professionals . The professionals who use rubber are mainly responsible for the processing of rubber raw materials, rubber products manufacturers and tire manufacturers .

How much does the cost price of silicone and rubber cost?

The price of silicone is relatively high, because the processing process of silicone is complex, and it needs to go through a series of steps such as rubber mixing, molding, vulcanization and so on. In addition, silicone is insoluble in water and any solvent, and has a high degree of chemical stability, which also increases its production cost.

The price of rubber varies according to the type and origin. For example, the price of natural rubber is affected by factors such as the price of glue drying glue, cutting labor costs and processing costs.

Conclusion

Choosing between silicone and rubber can be challenging. This is because both have their own advantages and disadvantages. However, the service life of silicone is longer than rubber, it can withstand continuous external forces and pressure for a much longer time than rubber, and it will not corroded or cracked in the process, and its resistance to temperature is stronger than rubber. These unique properties make silicone an ideal material and choice for chemical sealing, medical applications and the food processing industry.

As a professional manufacturer in designing and manufacturing high-quality LSR/SSR baby products in China for over 16 years’ experience . Jution silicone work with the baby products brands/wholesale/retails/ corporate gifts company and offer a range of services from sketch to contract Manufacturing meet the unique needs of each silicone baby project.

Contact Jution, Jution silicone support your baby silicone products brand to be the baby and parents preferred brand.