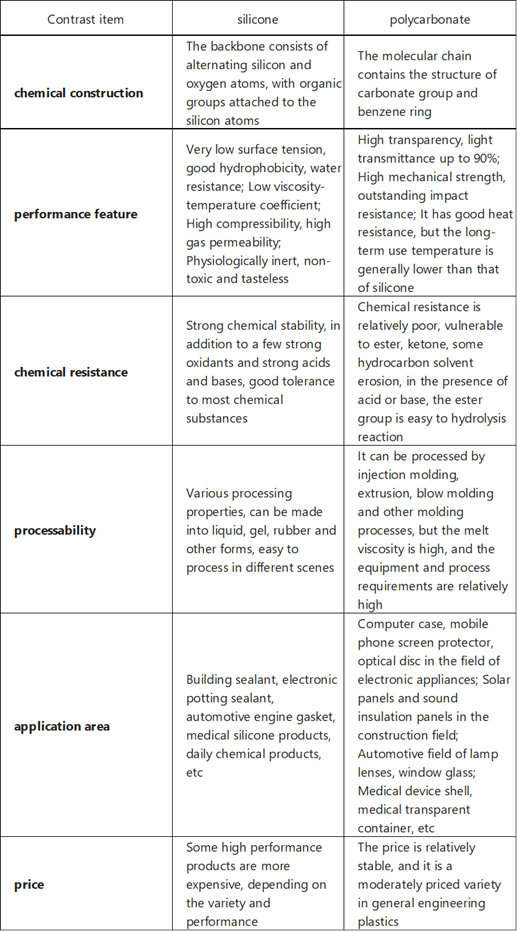

Silicone and Polycarbonate

What is silicone?

Silicone is a kind of highly active adsorption material, belonging to the amorphous substance, insoluble in water and any solvent, non-toxic and tasteless, its main component is silicone dioxide chemical stability, in addition to strong alkali, hydrofluoric acid does not react with any substance.

Silicone has the characteristics of high absorption, good thermal stability, stable chemical properties and high mechanical strength.

What is polycarbonate?

Polycarbonate is a kind of high molecular polymer containing carbonate group . According to the structure of the ester group, polycarbonate can be divided into aliphatic, aromatic and aliphatic – aromatic types. Among them, aromatic polycarbonate has obtained industrial production because of its excellent mechanical properties, and has become the fastest growing general engineering plastic among the five engineering plastics.

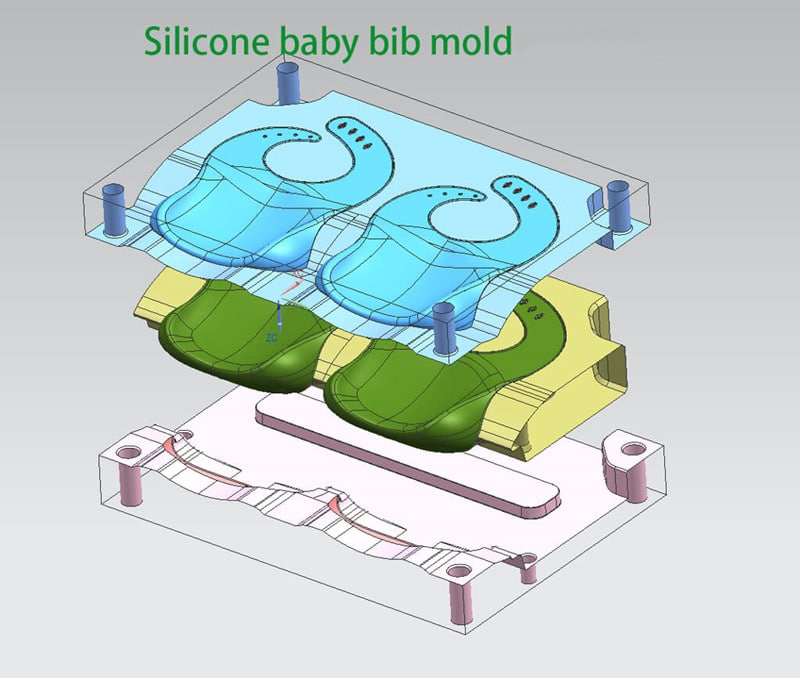

How can silicone be made?

Silicone products are mainly divided into the following molding methods:

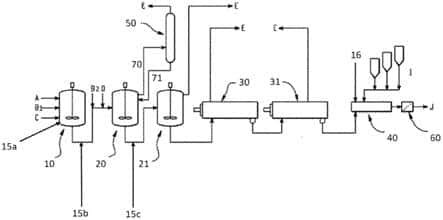

How is polycarbonate made?

At this stage, polycarbonate production generally has two methods: one is phosgene process; the second is the melting method.

Due to the highly toxic phosgene, coupled with the increasing attention of the public to environmental issues, the new PC production base is almost all using a more environmentally friendly melting method. Although the laboratory preparation of polycarbonate is only a one-step reaction, it is very simple, but in actual production, all raw materials must start from the most basic chemical products and complete the preparation step by step, which is a very complex systematic project.

Where can we use silicone?

- Electronic and electrical appliances: silicone also has a variety of applications in the field of electronic and electrical appliances, such as the sealing ring of power sockets, the charging interface sealing ring of mobile phones, etc. These applications prevent the intrusion of dust and moisture, ensuring the proper operation of the equipment .

- Medical devices: Silicone is also used to make medical devices, such as catheters, drainage tubes and so on. These products are biocompatible, easy to clean and disinfect, and ensure patient safety .

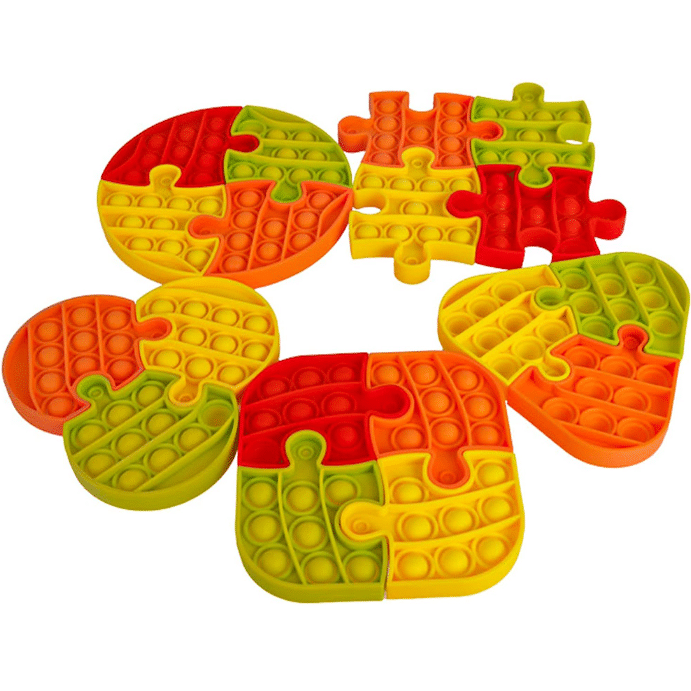

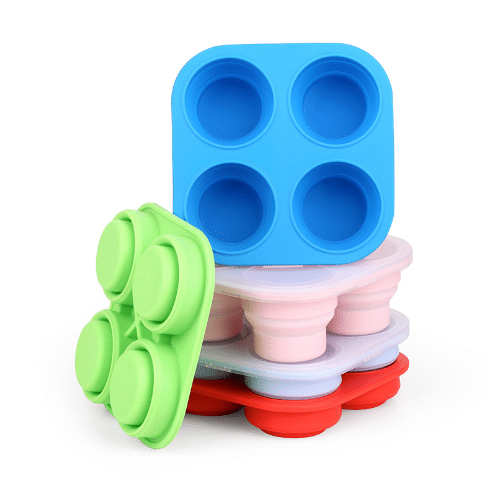

- Maternal and infant products: silicone products have a wide range of applications in the field of maternal and infant, such as silicone spoons, bowls, dinner plates, pacifiers and so on. These products are non-toxic, odorless and safe for babies .

- Beauty and skin care: silicone is also widely used in the beauty field, such as face brush, makeup brush cleaning pad, powder puff and so on. These products can help users better beauty and skin care .

Where can we use polycarbonate?

Building materials industry: polycarbonate sheet has good light transmission, impact resistance, resistance to ultraviolet radiation and the dimensional stability of its products and good molding processing performance, so that it has obvious technical performance advantages than the inorganic glass traditionally used in the construction industry.

Automotive manufacturing: Polycarbonate is suitable for the production of various parts of cars and light trucks, mainly concentrated in lighting systems, instrument panels, heating panels, defroster and polycarbonate alloy bumpers.

Packaging field: Because polycarbonate products have the advantages of light weight, impact resistance and good transparency, no deformation and transparency when washed with hot water and corrosive solutions, PC bottles have completely replaced glass bottles in some areas.

Why is silicone used in different fields?

Silicone has excellent physical and chemical properties. Silicone is a kind of polymer material composed of silicone and oxygen, which has the characteristics of flexible texture, strong plasticity and durability, and is suitable for the processing of various complex shapes . In addition, silicone also has excellent temperature resistance, weather resistance and chemical stability, can maintain stable performance in extreme environments, insoluble in water and any solvent, in addition to strong alkali, hydrofluoric acid does not react with any substance . These characteristics make silicone perform well in many fields.

Why are polycarbonates used in different fields?

Polycarbonate is a kind of carbonate polyester, colorless and transparent, with high impact strength, electrical insulation properties and good dimensional stability, with excellent chemical resistance, can resist a variety of acids, alkalis and oil erosion. However, it is not resistant to ultraviolet light and strong alkali, long-term exposure may lead to decreased performance, poor hydrolysis resistance, and is not suitable for products that are repeatedly subjected to high pressure steam.

When do you choose to use silicone or polycarbonate?

Because the silicone has excellent temperature resistance, corrosion resistance, and good flexibility and sealing performance, it is often used in high temperature, high pressure, high durability and often used in the need of high temperature resistance, high pressure, high durability and good flexibility and sealing;

Polycarbonate is a thermoplastic polymer material, with good mechanical strength, impact resistance and heat resistance, but also has good transparency and surface gloss, suitable for good mechanical strength, impact resistance, heat resistance, transparency and surface gloss occasions .

How much silicone and polycarbonate costs need to cost?

From the perspective of material characteristics and application fields, the cost of polycarbonate is generally higher than that of silicone. However, the specific cost will also be affected by raw material quality, production process, market demand and other factors, so in practical applications, it needs to be evaluated according to the specific situation.

Conclusion

Silicone toys are becoming an indispensable helper in the parenting life of new parents due to their safety, softness, bite resistance, durability and environmental protection. Choosing the right silicone toys according to the baby’s age and needs can not only reduce the parenting pressure of parents, but also enhance the baby’s sensory experience and give the child a happy childhood!