Water Transfer Printing patterns or logos on silicone products

Water transfer printing, also known as immersion printing, water transfer imaging, hydro dipping, water marbling, cubic printing, Hydrographics, or HydroGraphics. It is a decorative coating technology that allows you to apply detailed patterns and artwork onto 3-dimensional objects. Water transfer printing boasts strong visual impact, rapid product updates, and is ideal for limited-edition/collaboration products. Therefore, it’s favored by brands, IP partners, and gift retailers. The typical process involves floating a PVA (polyvinyl alcohol) film with the printed design on water, allowing it to absorb water and “expand,” then spraying an activator to dissolve the film base, liquefy the ink layer, and form a transferable floating layer. The workpiece is then slowly pressed into the water at an angle to cover the design, and finally, residual PVA is rinsed off and a protective varnish is applied.

However, silicone is inherently “difficult to color/paint/adhere”: it has low surface energy, poor wettability, and is non-sticky. Even if the pattern is successfully transferred, it may peel off, flake, crack, become sticky, or have dull colors when washed, rubbed, or bent. Therefore, the key to the success of silicone water transfer printing is not “whether water transfer printing is possible,” but rather: (1) whether the silicone surface activation and primer system are stable; (2) whether the primer/color paint and activator are correctly matched; (3) whether the clear varnish protective layer is sufficiently wear-resistant and washable; and (4) whether the mass production process control addresses “soft material deformation, surface contamination, and uneven activator spraying.”

What is Water Transfer Printing?

Water Transfer Printing, known as Hydrographics, Immersion Printing, or 3D Cubic Printing is a technology that decorates 3D-shape parts with exceptional color and appearance. It allows a manufacturer or brand to make parts or products with virtually unlimited appearance options.

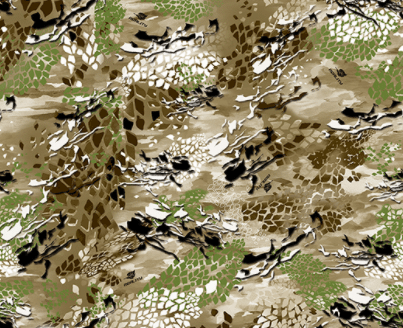

They can be made with unusual colors or realistic patterns. There are lots of materials for Hydro Dipping. They allow patterns and designs to be applied to any shaped objects. Any object that can hold a base coat and be safely submerged in water can be dipped. Surfaces such as dashboards, hunting equipment, camouflage items, silicone parts and many others, can be customized with this process. This is the same process used by major manufacturers to decorate their products. Simply clean the item, buff it, and apply a base coat. After that, dip it (applying the pattern), rinse, dry and clear coat.

A Brief History Of Water Transfer Printing

The exact origin of the water transfer printing process is unclear, though it shares some basic qualities with the traditional Japanese paper marbling method, suminagashi. However, the first hydrographic apparatus registered for a US patent was by Motoyasu Nakanishi of Cubic Engineering KK on July 26, 1982.

Digging for the roots of the origins of Hydro Dipping can be an interesting exercise because companies change their names and are acquired over the decades. and because people on the internet take the easy way out in their research.

Regardless of the patent date, the patent tells us that the inventor of the record is Motoyasu Nakanishi, and the patent was assigned to Kabushiki Kaisha Kobayashi.

How Does Water Transfer Printing work?

Before doing the Water Transfer Printing, We need make an AI file for the pattern you would like to put on your OEM products. Then ink was printed into a large roll of PVA film same as the pattern. It is water-soluble and will start to dissolve when floated on water and the activator chemical is applied. There are wide ranges of water transfer printing films and the most popular patterns include camo, wood grain, carbon fiber, marble, and camo. The camo film is the most popular pattern and is also the common pattern for hydro dipping guns.

After that, Generally, the process of water transfer printing, aqua printing, or hydro dipping is quite simple. That is to spray base coating on objects, cover by water transfer printing patterns, and spray final top coating. In the process, the substrate piece to be printed first goes through the entire painting process: surface preparation, priming, painting, and clear coating.

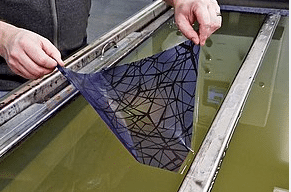

Depending on some types of plastics, some substrates may also need to be flame-treated before a base coat is applied. A PVA hydrographic film, which has been printed on with a desired graphic image using latex or pigment-based inks, is carefully placed on the water’s surface in the dipping tank. The recommended water temperature for the dip tank is 90°F (32°C). The clear hydrographic film is water-soluble and should dwell on top of the water for 60-75 seconds. Safely using a fitted respirator, the film is then sprayed with an activator solution to dissolve the film and return it to its fluid state.

Once dipping is begun, the surface tension of the water will allow the pattern to curve around any shape. Any remaining residue is then rinsed off thoroughly. The ink adheres to the desired surface and it cannot be washed off easily. It is then allowed to dry.

How to print on silicone Products?

Pad Printing Pattern or Logo on Silicone Products

Laser Engraving Patterns or Logos on Silicone Products

How to Print Logo or Pattern on Silicone Bibs?

Screen Printing: Print Patterns On Silicone Products

Heat Transfer Printing Process: Print Patterns On Silicone Product

What Are The Steps Of Water Transfer Printing on your silicone products?

Follow these 7 simple steps and you will turn the concept into liquid reality or start your hydrographic business.

- Step 1: Apply the base coat. decontamination, degreasing, rust removal, impurity removal, or flame treatment according to the material of the workpiece to be transferred;

- Step 2: Ensure the surface dries thoroughly after applying the base coat.

- Step 3: Place the water transfer film above the water for a while and then spray the activator. Before laying the hydrographic film on top of the water’s surface, it works best to cradle the film and roll one corner slowly and smoothly onto the water to the other corner. Avoid getting any air bubbles under the film

- Step 4: Dip it (Apply the pattern) A substrate should typically be dipped at about a 45° angle

- Step 5: Rinsing

- Step 6: Spray Top Coat

- Step 7: Drying

Water Transfer Printing service

JUTION provides professional Water Transfer Printing service. We can perform Water Transfer Printing of logos and patterns on various silicone products according to user needs.

If you need to print your own designed patterns or logos on 3D objects, such as silicone bibs, cups, bowls, etc. And the pattern and logo are stable and will not fade. We recommend using water transfer printing.

Advantages And Disadvantages Of Water Transfer Printing

Advantages of water Transfer printing:

Aesthetics: Any image can be transferred to the product, breaking through the past printing technology, and realizing your printing needs.

The images also have the ability to be very detailed, which is perfect for items that are intended to have a large aesthetic appeal. The versatility is such that pretty much anything you could print from a home printer, can also be printed using hydrographics onto a 3D object.

Innovative: Water transfer printing technology can overcome the problems of complex shapes and dead corners that cannot be produced by general traditional printing and thermal transfer, pad printing, screen printing, and surface coating. water transfer printing is highly versatile and cost effective for the right kinds of items. The process also manages to avoid many of the potential failure points and problems associated with other printing methods such as screen printing or hot printing. This allows for a good level of consistency over large runs of items.

Extensiveness: It is suitable for surface printing of hardware, plastics, leather, glass, silicone, wood, and other products (cloth and paper are not applicable). It is not limited by the shape of the product. It can also be applied to products that are particularly complex or large, super long, and super-wide.

Personalization: Do whatever you want, and design any patterns according to customer needs.

High efficiency: No need for plate making, direct drawing, fast transfer (the whole process only takes 30 minutes, suitable for proofing).

Superiority: Fast proofing, curved surface printing, personalized printing, small quantity, and much non-paper and cloth printed matter.

Environmental protection: Residues and wastewater will not pollute the environment

Durable: The ink applied via water transfer printing is also highly durable, which makes it suitable for use on the exterior of vehicles. However, it will normally also receive a protective coating of some sort to ensure the image will last for years without fading or becoming damaged.

Disadvantages Of Water Transfer Printing

- The transfer effect is too poor;

- A large amount of polluted water is generated;

- The material cost and labor costs are extremely high.

Choosing The Right Substrate For Water Transfer Printing

- Film selection: One of the key elements in achieving a successful hydro dipping project is selecting the right water transfer printing film. With numerous options available in the market, it’s important to consider several factors to ensure the perfect match between your project requirements and the hydro-dipping film.

- Consider the Material of what you want to print, such as silicone, plastic, or wood.

- Set the film: cut the film paper of the same size as the workpiece to be transferred, and lay it flat on the water surface (the printing side is facing down);

Who like use the water transfer printing on silicone products?

Brand owners (DTC/Baby & Maternity/Lifestyle): Seek brand identity and serialized designs using patterns.

IP licensing/gift channels: Require complex patterns, strong visual appeal, and rapid iteration.

3C accessories/Sports & Outdoors: Seek durable, personalized textures (carbon fiber/camouflage).

OEM/ODM sourcing: Focus on yield rate, adhesion, washability, abrasion resistance, compliance, and stable delivery time.

When you can Choose Water Transfer Printing?

With complex, multi-color/continuous textures are required and the product allows for a “coated + varnish” structure.

When the product lifecycle is short and the pattern changes frequently (marketing-driven).

Not recommended for: areas subject to prolonged high friction, frequent high-temperature dishwashers, or areas explicitly requiring “no coating/no ink” (unless you have a fully validated and compliant materials system).

Where is Water Transfer Printing Most Suitable?

Best suited for: decorative surfaces, low-friction areas, and visually appealing surfaces (such as the outside of cup sleeves, handles, and protective covers).

Caution advised for: high bend points, sealing surfaces, lip contact surfaces, biting areas, and high-friction grip areas (unless the varnish system is sufficiently abrasion- and sweat-resistant).

Frequently Asked Questions About Water Transfer Printing

Q: Can water transfer printing be done directly on bare silicone?

A: It’s strongly discouraged. Water transfer printing patterns mainly rely on the primer/varnish system for adhesion, but silicone has low surface energy and usually requires surface activation and a primer to improve adhesion stability.

Q: Why does the same film sometimes adhere and sometimes not?

A: The amount and uniformity of the activator spraying are key variables; too much or too little can lead to failure. Public information also lists “improper application of activator” as a common cause of failure.

Q: Will soft silicone affect water transfer printing?

A: Yes. Soft materials are easily stretched or deformed during immersion/coating, leading to pattern distortion or poor adhesion. Some sources also suggest that soft silicone/soft rubber is not recommended.

Q: What makes the pattern wear-resistant?

A: Mainly the protective varnish layer; industry guidelines generally emphasize the need to apply a varnish after transfer to protect the pattern from friction and oil stains.

Q: How long should the water transfer film be left in water?

A: Common process recommendations include a soaking time of approximately 60–75 seconds, followed by activation.

Q: What are the considerations for the water immersion angle?

A: Many operating guidelines recommend an immersion angle of approximately 45° for more even coating and reduced bubbles/fraying.

Q: How do I determine if the adhesion meets the standard?

A: Standardized evaluation can be performed using the ISO 2409 cross-cut test or the ASTM D3359 tape test.

Q: What happens if rinsing is incomplete?

A: Residual PVA can cause the surface to become sticky, attract dust, and affect varnish adhesion and appearance. Process instructions also emphasize rinsing off any residual film after transfer.

Q: Is water transfer printing suitable for “food contact/mouth contact areas”?

A: Unless you have a complete coating system compliance and migration verification, it is not recommended to apply the coating to lips/bite contact surfaces; water transfer printing is more recommended for decorative surfaces.

Q: If the customer requires “dishwasher resistance,” can water transfer printing still be done? A: You can try it, but you must go for the “durability upgrade” route: surfactant + high adhesion primer + high abrasion varnish, and conduct dishwasher cycle and adhesion retest (let the data speak for itself, not just verbal promises).

Q: Can water Transfer printing be used in Silicone baby products?

Yes, water Transfer printing can be used on silicone baby bibs, cups, bowls or any silicone products to create unique and personalized designs.

Q: What is the difference between water Transfer printing compare Screen Printing, Heat Transfer Printing, In-Mold Decoration?

Can printing uneven surfaces among other things. Can get colorful, Camouflage, Carbon Fiber, Wood Grain colors/Can Change color and pattern by Film

Q: What is the cost of Water Transfer Printing?

A: 0.5USD-1.9USD/color depend on the size and shape.

Conclusion

Water Transfer Printing is a process of decorative coating technology that allows you to apply detailed patterns and artwork onto 3-dimensional objects. This coating method is used widely for decorating silicone products, silicone baby bibs, silicone baby mats and many other items.

Water Transfer Printing a logo or pattern on silicone baby products is a great way to give your brand a professional look and feel. With the right tools and techniques, you can easily print your logo or pattern onto silicone baby products with high-quality results. We hope that our guide has helped you understand how to print a logo or pattern on silicone baby cups so that you can create stunning products for your business.