Do you know the temperature at which silicone melts

What is silicone?

Silicone is a granular porous silicone hydrate, the appearance is transparent or milky white, has an open porous structure, has a strong adsorption capacity, its main component is silicone.

Silicone is insoluble in water and any solvent, non-toxic and tasteless, chemically stable, in addition to strong alkali and hydrofluoric acid, does not react with other substances.

What are the factors that affect the melting of silicone?

What is the melting temperature range of all kinds of silicone?

The melting temperature range of silicone varies according to different models and uses.

- Ordinary silicone: The high temperature resistance range is usually between 200℃ and 300℃. In this temperature range, silicone is able to maintain its physical and chemical properties.

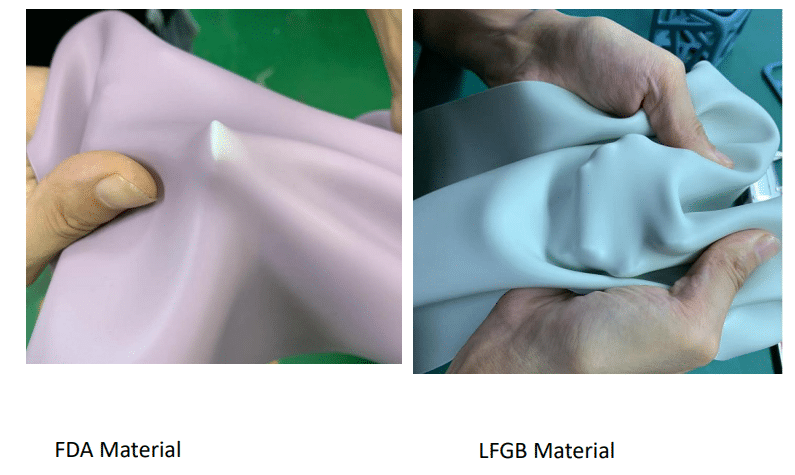

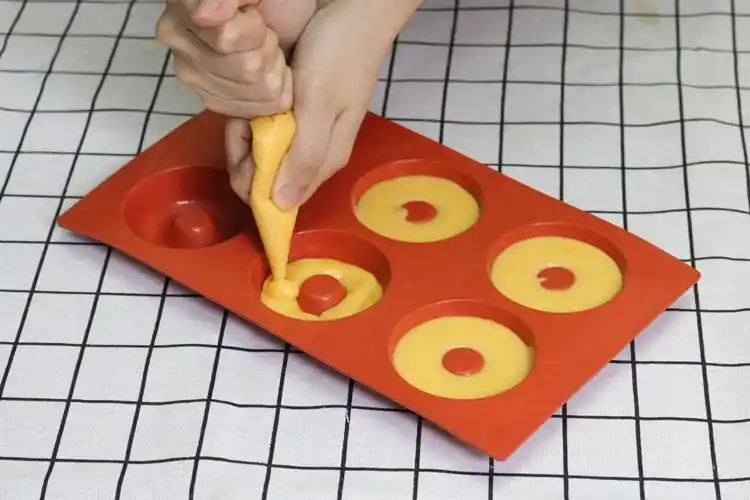

- Food-grade silicone: The temperature range is about -50 ° C to 250 ° C, and no chemical reaction or decomposition of colored objects will occur in this temperature range.

- Special silicone: Some special silicone can increase the high temperature resistance to about 350 ° C in a short time (such as two hours), which is used for occasions that need to withstand extremely high temperature environments.

Why should the melting point of silicone be tested?

Product quality assurance: Melting point detection is an important part of product quality control, through the detection can determine whether the silicone products meet the application requirements, to avoid product defects caused by unqualified melting point.

Material quality control: The melting point testing of silicone helps to ensure that the material retains its expected properties during processing and use.

Safety and reliability: In some high-temperature applications, the melting point detection of silicone is particularly important to ensure the safety and reliability of the product in extreme environments.

How to determine the melting temperature of silicone?

Thermogravimetry (TGA) : Determine the thermal stability of a sample by measuring its mass change during heating. TGA is suitable for the study of the thermal degradation process of silicone at high temperatures and the analysis of toxic substances that may migrate out .

Differential scanning calorimetry (DSC) : By measuring the heat flow difference between the sample and the reference, DSC accurately records the thermal effect of the sample during heating or cooling, so as to determine its melting point. The method has the advantages of high sensitivity, good resolution and strong data reproducibility, and is widely used in the melting point detection of aviation materials and silicone .

Vica softening point test: The softening point or hot deformation temperature is determined by measuring the temperature when the sample reaches a certain deformation under a specific load.

How to measure the melting point of silicone?

Prepare heating equipment: Equipment such as a melting furnace, hot plate or heat gun can be used.

Sample preparation: Take the appropriate amount of silicone sample and place it in the appropriate container.

Heating process: Gradually increase the temperature of the heating equipment to the melting point of the silicone (usually about 200 ° C). During the heating process, the temperature should be controlled to avoid excessive decomposition of silicone or harmful gases

Observation and record: When the silicone begins to melt, record the temperature and stir well with a tool to avoid partial melting.

heat gun

Where is the melting temperature of silicone applied in real life?

Conclusion

Through the detailed analysis of the application of silicone temperature, I believe that we have a more in-depth understanding of silicone. Choosing the right silicone products and using them correctly will bring more convenience and security to your life and work. In the future, with the progress of science and technology, I believe there will be more high-performance silicone products coming out, bringing more possibilities to our lives.

Would you like to create your silicone products brand or look for reliable and safe silicone products with your logo for your Event? Jution Silicone can help. Get an online quote with free design from us for quality silicone products within days.