Silicone placemat and bib set, helping to cultivate your baby’s dining habits

As a silicone industry expert, I’ve witnessed how silicone materials have revolutionized the infant and toddler products market from an industrial perspective. Silicone placemat and bib sets are more than just simple dining tools; they’re scientific teaching aids that foster healthy eating habits and promote fine motor development in infants and toddlers. Based on my professional experience, combined with industry data and customer feedback, this article will provide an in-depth analysis of the product value and key considerations for choosing a silicone placemat and bib set, as well as purchase precautions and cleaning and maintenance methods.

If you’re interested in silicone placemats and bibs or would like to learn more, please read this article.

What are silicone placemat and silicone bib sets?

The silicone placemat and bib set is a baby tableware accessory made primarily of silicone and hot-pressed at high temperatures.

Silicone placemats are commonly used on dining tables to prevent food from coming into direct contact with the surface. They also feature a non-slip finish, providing anti-slip, stain-resistant, and heat-insulating properties. Some also feature recessed areas for placing food directly on the table.

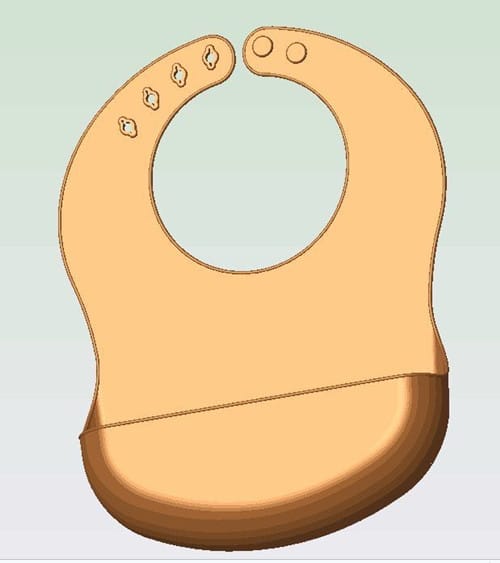

Silicone bibs are soft and comfortable to wear around your baby’s neck, and feature a large food scoop to effectively catch any spills and make cleaning easy after meals.

Why are silicone placemat and silicone bib sets necessary?

- Soft and Non-Toxic: Both the placemat and bib are made of food-grade silicone, making them soft and non-toxic, harmless to babies.

- Durable and Easy to Wash: The smooth surface of the silicone placemat and bib makes them impervious to stains and easy to clean with a simple wipe.

- Versatile: Suitable for infants and patients, they can be used to catch dropped food, preventing stains on clothing and surfaces during meals.

- Easy to Carry: The silicone placemat and bib are made of soft material and can be rolled up for easy transport.

Who are the target users of silicone placemat and silicone bib sets?

Home users: With growing environmental awareness, more and more families are choosing safe and environmentally friendly silicone placemats and bibs to replace polluting disposable plastic tableware.

Travelers: Soft silicone products are convenient to carry around. Their safety, non-toxicity, and easy cleanability make them an ideal choice for those who love to travel.

Toddlers: Silicone placemats and bibs are primarily targeted at toddlers, especially those in the feeding and self-feeding stages. Silicone products are non-slip, durable, portable, and easy to clean, making them ideal for daily dining and drinking.

If you require custom silicone products, please contact JUTION.

What are the usage scenarios of silicone placemat and silicone bib sets?

When to use silicone placemat and silicone bib sets?

Early stage of complementary food:

After 6 months, the baby has started to eat complementary food, and often eats food everywhere. The soft bib can effectively prevent the baby’s clothes from getting dirty, and the silicone placemat can catch the fallen food, giving the baby a more comfortable dining experience.

Self-feeding training period:

When the baby starts to learn to feed himself, he needs a bib to protect his clothes from stains; a placemat to fix the place of the plate and catch the dropped food and spoon.

How are silicone placemat and silicone bib sets made?

Material selection

Medical grade platinum-cured silicone

Hardness: Shore A 40-50 for placemats, Shore A 20-30 for bibs

Masterbatch: Food-grade color powder, FDA-approved

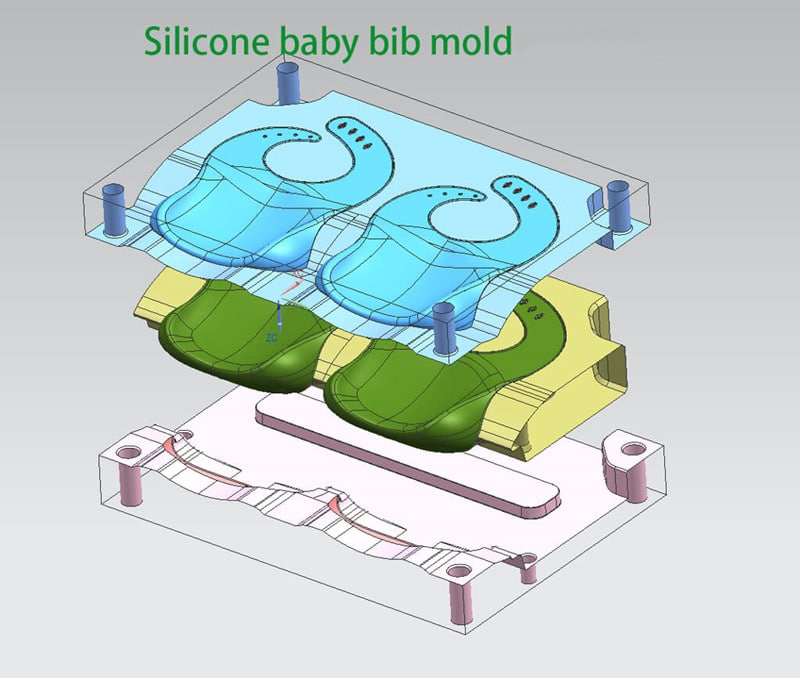

Mold design

Placemat: Anti-slip ribbed design, 0.5-1mm depth

Bib: Three-dimensional grooves, 3-5cm depth, foldable

No sharp corners, all edges are rounded.

Mixing

The prepared raw materials are placed in a mixer for processing to thoroughly mix and soften the silicone rubber. During this process, a vulcanizing agent is added to enhance the durability and elasticity of the silicone rubber product.

Molding Process

Compression molding: The mixed silicone rubber is placed in a hydraulic press and formed into the desired shape through high temperature and pressure. Silicone products produced through compression molding possess high density and strength, making them suitable for a variety of daily necessities, such as silicone tableware and silicone baby bottles.

Injection molding: The silicone raw material is heated to a high temperature, injected into a mold, and then formed using pressure. Silicone products produced through injection molding possess high precision and finish, making them suitable for silicone tableware requiring high precision.

Other molding processes include calendering, drop molding, and vacuum forming.

Curing and Post-Processing

After forming, silicone tableware needs to be cured, typically through hot or cold vulcanization. This allows the vulcanizing agent in the silicone rubber to react chemically, forming a stable structure. Cured silicone tableware also requires post-processing, including deburring, secondary vulcanization, cleaning, and drying, to improve its appearance and performance.

Quality Testing

Physical Properties: Tensile Strength >10MPa, Tear Strength >25kN/m

Chemical Safety: FDA, LFGB, and REACH certified

Usage Testing: Anti-slip, load-bearing, and folding tests

At JUTION, we provide the most sincere, one-stop service to create the silicone products of your dreams.

How to control the quality and safety of silicone placemat and silicone bib sets?

Raw Material Control

Raw Material Selection: Food-grade silicone that meets the GB4806.11-2016 standard must be used. Such materials must be certified by international standards such as the FDA and LFGB, non-toxic, and heat-resistant (≥200°C). Industrial-grade silicone, due to the presence of harmful substances such as plasticizers, is strictly prohibited for food contact.

Testing Parameters: Upon arrival, parameters such as volatile matter (≤0.5%), hardness deviation (±2 Shore A), and Mooney viscosity (40-60 MU) are tested to ensure molecular structure stability.

Production Process Control

Mold Precision: Molds must be precisely machined and polished to a mirror finish to ensure a flawless product appearance.

Mixing Process: A twin-rotor internal mixer is used, with an initial temperature of 20-25°C, a mixing time of 8-12 minutes, and a discharge temperature of ≤50°C to ensure compound uniformity.

Molding Parameters: During compression molding, control the temperature (solid silicone 160-180°C), pressure 8-15 MPa, and time accuracy to ±2°C to avoid bubbles and deformation.。

Finished Product Testing and Certification

Sensory Testing: The finished product must be odorless and free of impurities, resistant to high temperatures (≥200°C) and stable at low temperatures (-40°C).

Chemical Safety: Tests for heavy metal content, total migration, and potassium permanganate consumption are conducted to ensure the absence of harmful substances.

How to purchase the right silicone placemat and silicone bib sets?

Material: When purchasing, pay attention to whether the material meets national standards and whether the surface is smooth and free of cracks.

Inspect details: Ensure that the accessible edges of cutlery and bibs are not dangerously sharp to prevent injury during use.

Styles and Varieties: Silicone dinner placements and bibs come in a variety of styles, allowing you to choose the right silicone product based on your needs.

Design and Appearance: Silicone products are available in a variety of colors and styles. To enhance dining enjoyment, especially when purchasing for babies, consider choosing silicone tableware with a high aesthetic appeal.

How to use silicone placemat and silicone bib sets?

When using a silicone mat, be sure to position it correctly. For example, when using a silicone mat on a dining table, first wipe the surface with a damp cloth. Then, carefully press the mat into place evenly on the surface, avoiding any wrinkles or gaps that might affect the stability of the tableware.

Before use, clean the bib thoroughly to ensure it is free of dust and debris. Then, adjust the size of the silicone infant bib to the baby’s neck, ensuring it fits snugly and comfortably. Then, place the silicone bib around the baby’s neck and secure it with the button at the back of the neck.

How to clean and maintain silicone placemat and silicone bib sets?

We need to clean silicone products regularly. When cleaning, you can use mild detergent and soft cloth to gently wipe, or soak in warm water to clean. (Avoid using corrosive detergents or sharp objects to clean silicone products to avoid damaging the surface of the silicone products) After cleaning, dry thoroughly to ensure that no moisture remains.

When silicone products are not in use for extended periods, they should be neatly folded and stored in a dry, well-ventilated area. (Avoid direct sunlight, high temperatures, and contact with sharp objects.)

For more information about silicone products, please contact JUTION.

Conclusion

Babies in the sensorimotor stage adapt to their environment through perception and movement. At this time, we need to follow the baby’s nature, pay attention to the opportunities they gain and their potential for development, and provide them with safe and secure living supplies. Silicone placemats and bibs are not only convenient and practical, they do not put any pressure on the baby, and they can ensure that the baby’s mealtime is full of joy, making the baby healthier and happier as they grow up, and they can also bring convenience and protection to more families.