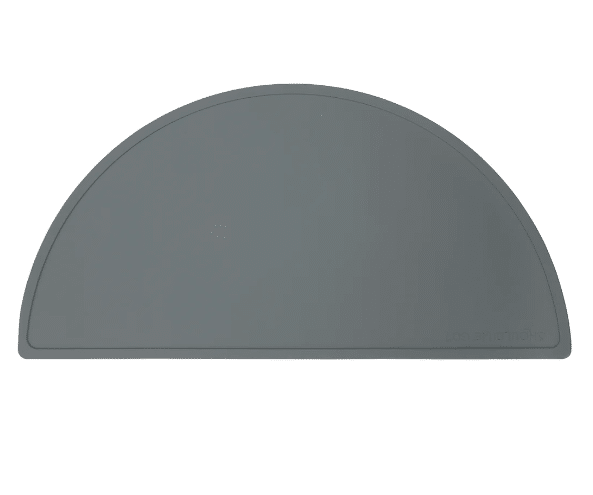

Semicircle Silicone Bath Mat

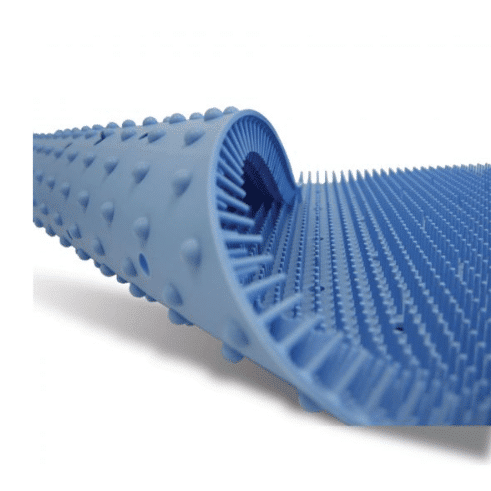

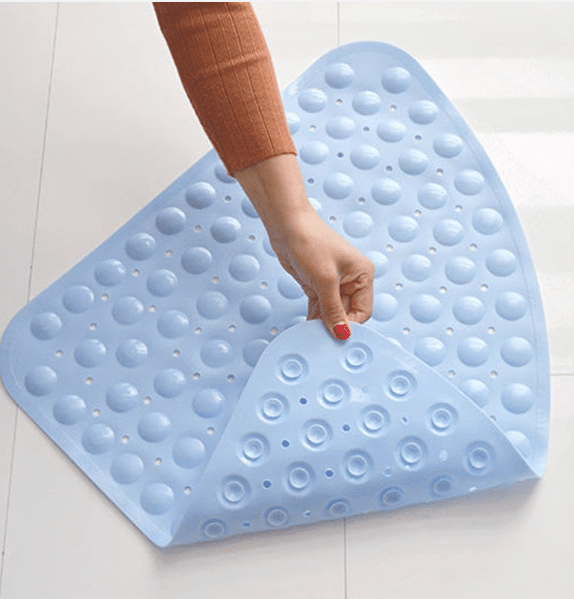

Semicircle Silicone Bath Mat is made of high-quality non-slip material, providing excellent traction and anti-slip properties to prevent slipping in the bathtub. Its textured surface enhances grip and ensures stability during use. It also comes with multiple strong suction cups to hold it securely in place and prevent it from moving while bathing.

The mat also has multiple drainage holes to allow water to flow through easily and prevent water accumulation. The holes also make the mat easy to clean and maintain – just rinse with water and hang to dry after use.

JUTION‘s customized Semicircle Silicone Bath Mat can be tailored to various sizes and specifications according to user requirements. We can imprint a variety of colors, patterns, and logos on the mats using commonly employed methods such as CNC Milling and laser Engraving.

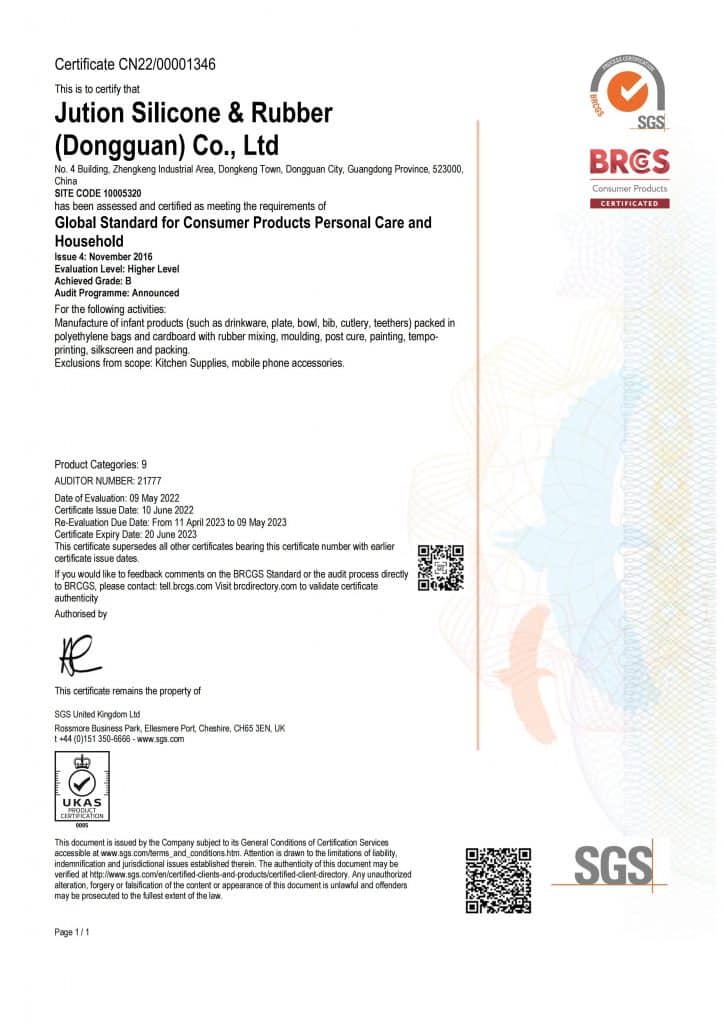

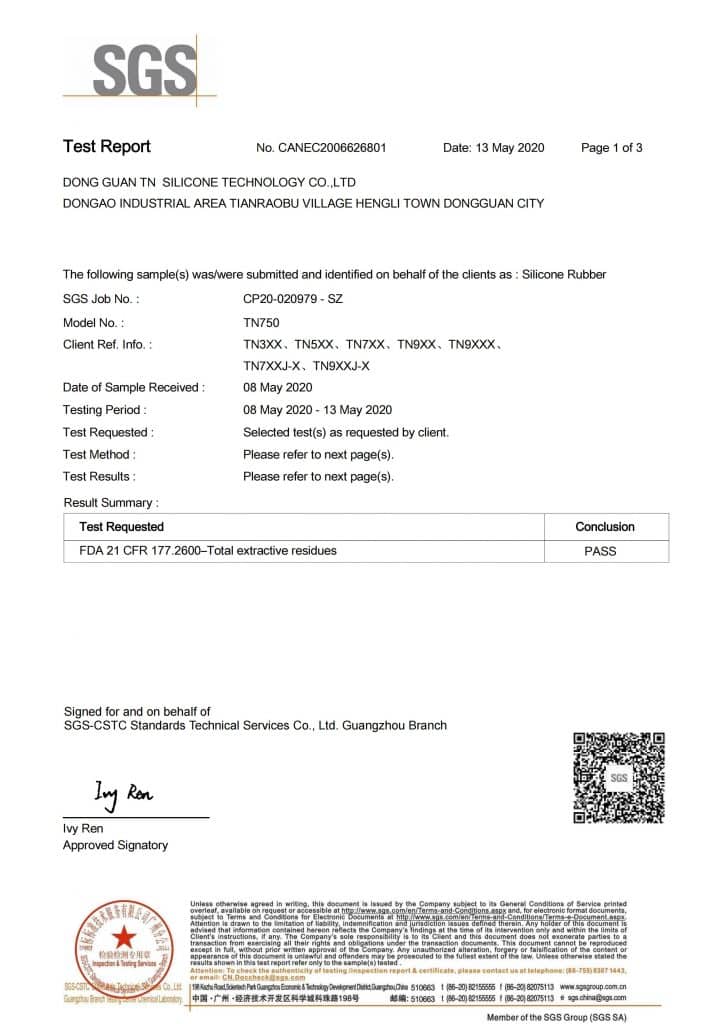

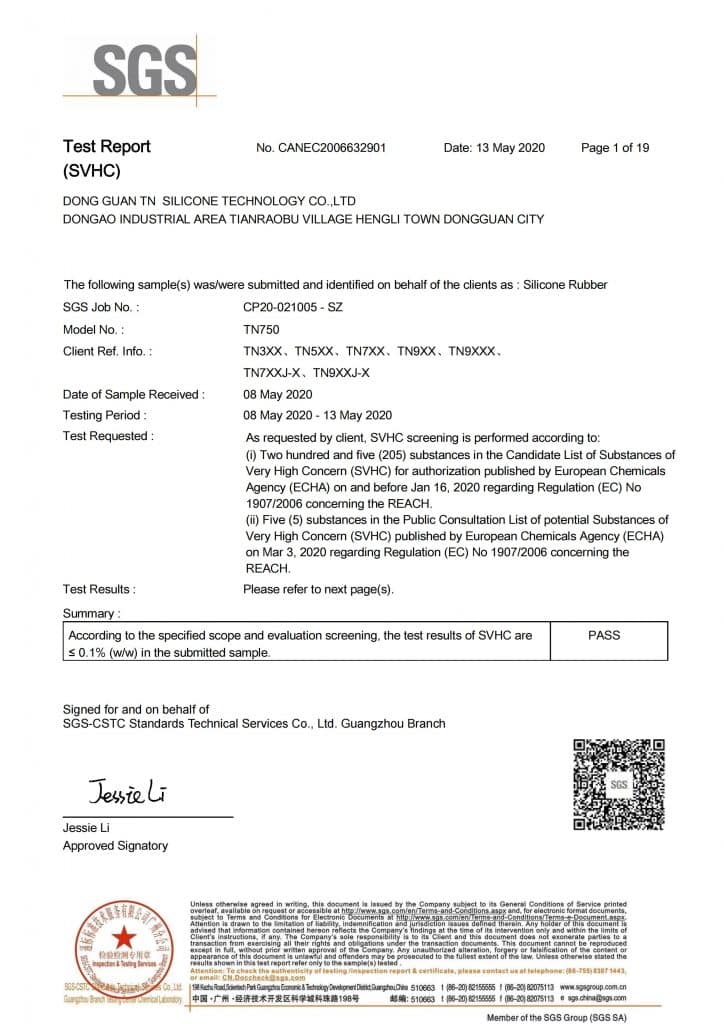

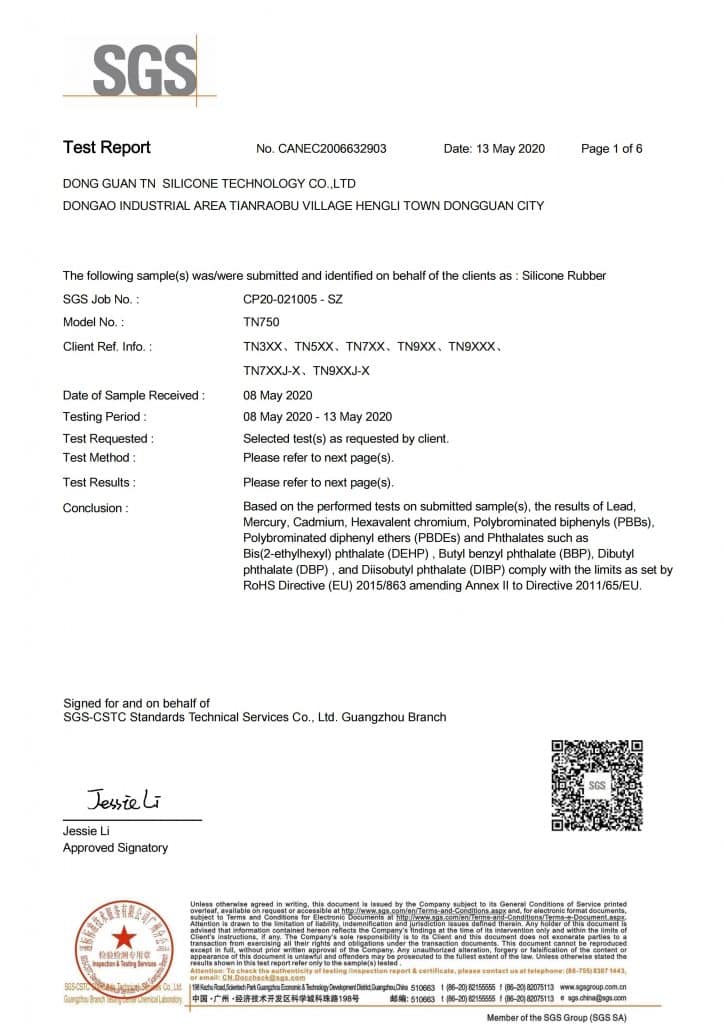

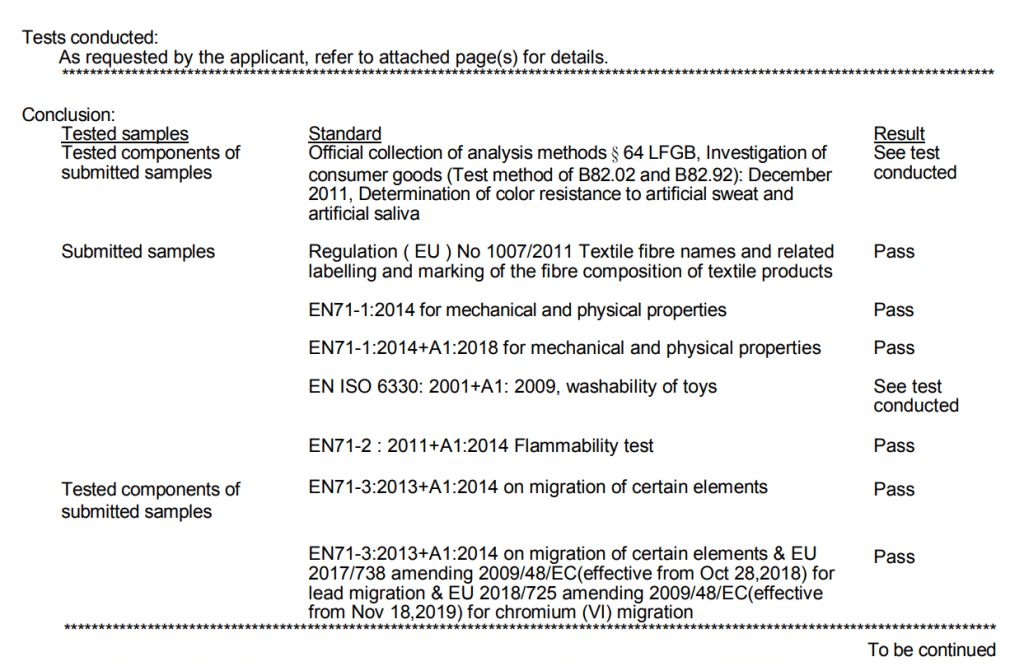

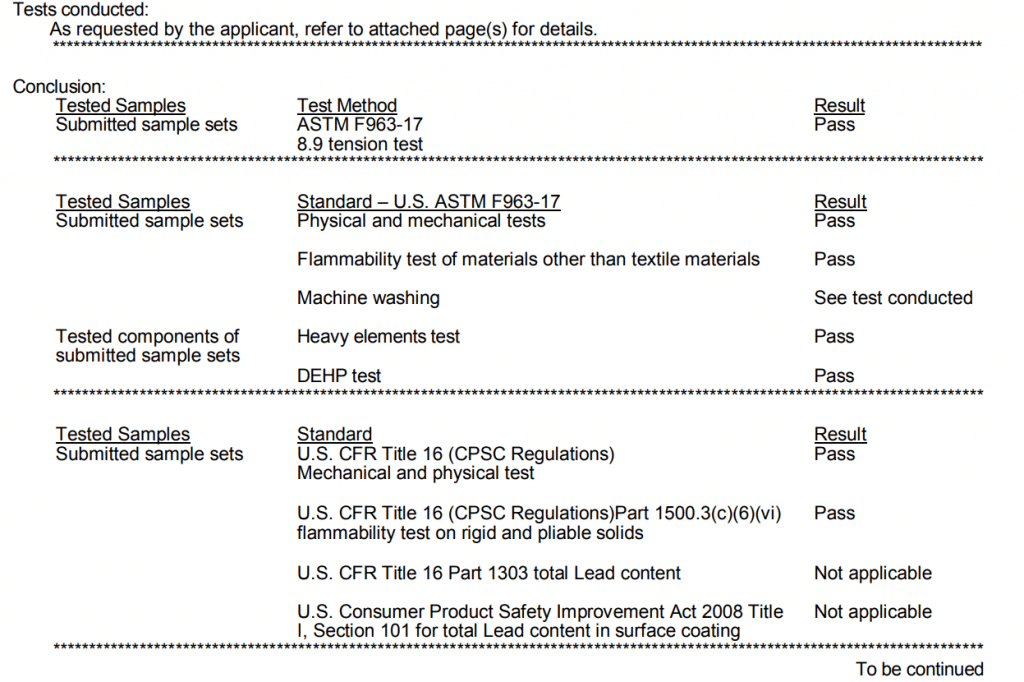

Our silicone material is food-grade platinum silicone that complies with FDA standards. you can purchase these materials directly from us for your own processing needs.

| 100% Food Grade Material | FDA standards, Platinum Silicone, BPA-free, Lead-free, Phthalate-free, Latex-free |

| Size | Small Scale: 4 inch |

| Large Scale: 16 inch | |

| thickness is 0.1-5 MM. | |

| Colors | Green, Orange, Yellow, Pink, Blue, White, Transparent, or Customized with the PMS Book |

| Production Processes | Compression molding |

| Logo or Pattern | Logos and patterns can be added according to user requirements |

Frequently bought together

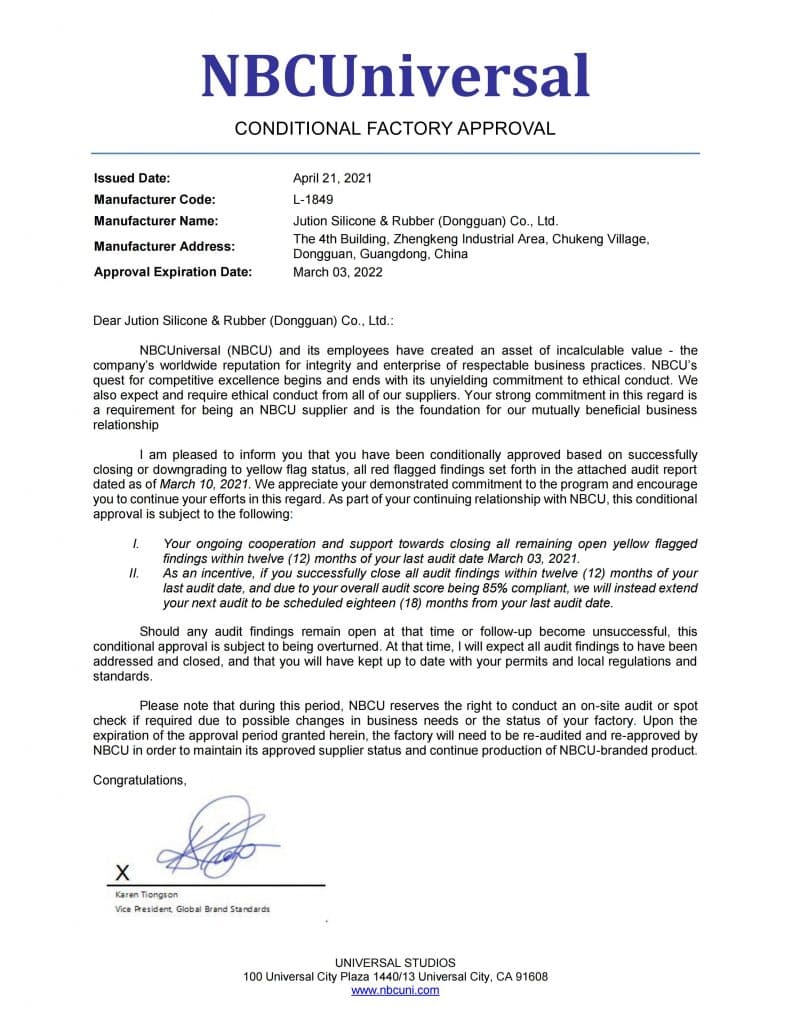

Let every baby in the world use safe and eco-friendly silicone products

The safety of silicone baby products is our top priority for us.We believe that all mothers hope to use high-quality baby products for their babies.

People Also Asked:

Still Have Questions?

If you cannot find an answer to your question in our FAQ, you can always contact us and we will be with you shortly.