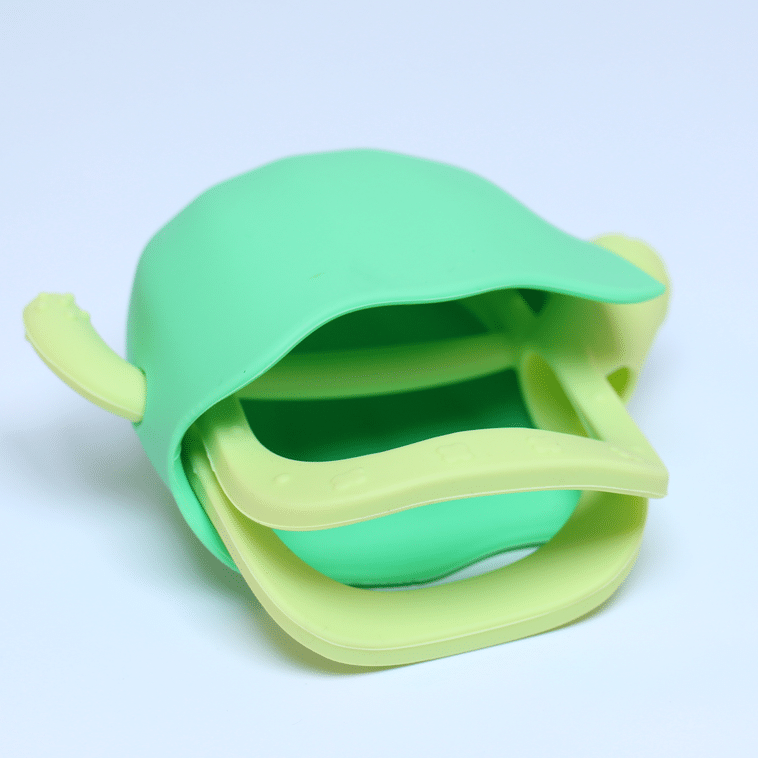

Silicone baby sensory ball, textured surface grasping training toy

As a professional who has been deeply engaged in the field of silicone materials for many years, I have witnessed how silicone materials have reshaped the landscape of maternal and infant products with its unparalleled safety and functionality. The early sensory development of infants and young children is very important. During the critical period of the baby’s growth, every touch and every grasp is contributing to the construction of their neural network. Today, we will focus on a product that seems simple but contains profound scientific principles-the silicone baby sensory ball. This article mainly introduces the definition and target users of the silicone baby sensory ball, the reasons why infants and young children need it and the specific usage scenarios, as well as its correct way to play and cleaning and maintenance methods.

If you are interested in the silicone baby sensory ball or want to know more about it, please read this article.

What is the silicone baby sensory ball?

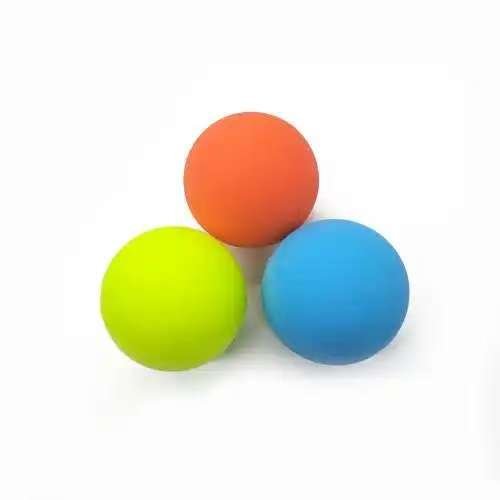

Silicone baby sensory balls are made of food-grade silicone and are specifically designed for tactile perception training and sensory stimulation.

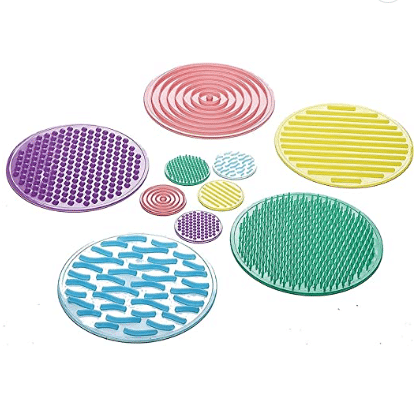

They are usually spherical in shape, vary in size, and have a variety of surface textures.

The material is generally soft and elastic.promote sensory development.

For some patients with tactile disorders, touching and operating the sensory balls, as well as assisting rehabilitation therapy, can help them gradually restore normal sensory functions.

Why use the silicone baby sensory balls?

Sensory integration training:

0-3 years old is the primary stage of sensory integration development for babies. The individual’s own physiological functions are improved and the basic abilities in multiple fields are initially developed. The baby has the basic abilities of feeling, cognition, language and social interaction to interact with the outside world. In the early education stage, it is necessary to use some toys to train the baby’s sensory integration.

Safe and harmless:

Silicone baby sensor balls are lighter than TPU ones, making them more suitable for younger babies. Furthermore, they are made of 100% food-grade silicone, making them safe for chewing and gnawing.

Early Childhood Education:

The diverse shapes of silicone baby sensor balls can also aid in cognitive development. Frequent handling stimulates hand nerves and improves finger dexterity and coordination.

Who are the target users of the silicone baby sensory balls?

Early childhood education institutions:

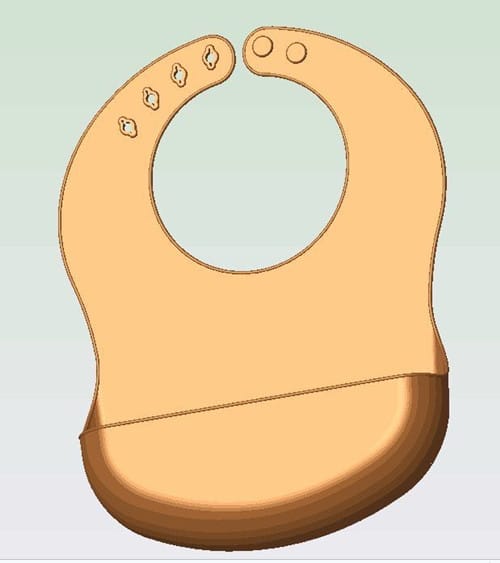

The silicone baby sensory ball is non-toxic and odorless, soft in texture, and has a textured surface design. It can be used by babies to chew and molar, and is especially suitable for babies in the critical period of sensory development to touch and explore.

Parents who focus on safety, environmental protection and early education:

Do you want your children to have access to some safe toys and have fun constructing and acquiring knowledge? Then don’t miss this silicone baby perception ball for perception training and sensory stimulation.

Medical institutions:

For patients with tactile impairments, medical institutions can purchase silicone baby sensory balls with different surface textures for patients to touch and operate to assist in rehabilitation treatment.

If you want more information about silicone products, you can contact us JUTION.

When is it appropriate to use the silicone baby sensory balls?

Where is the best place to use the silicone baby sensory balls?

How to produce silicone baby sensory balls?

Raw Material Selection

Food-grade liquid silicone rubber (such as addition-type two-component liquid silicone rubber) must be used. It is non-toxic, odorless, and age-resistant, and must pass SGS acute oral toxicity testing. This material is commonly used in infant and toddler products. After curing, it forms an elastomer that can withstand repeated compression and friction.

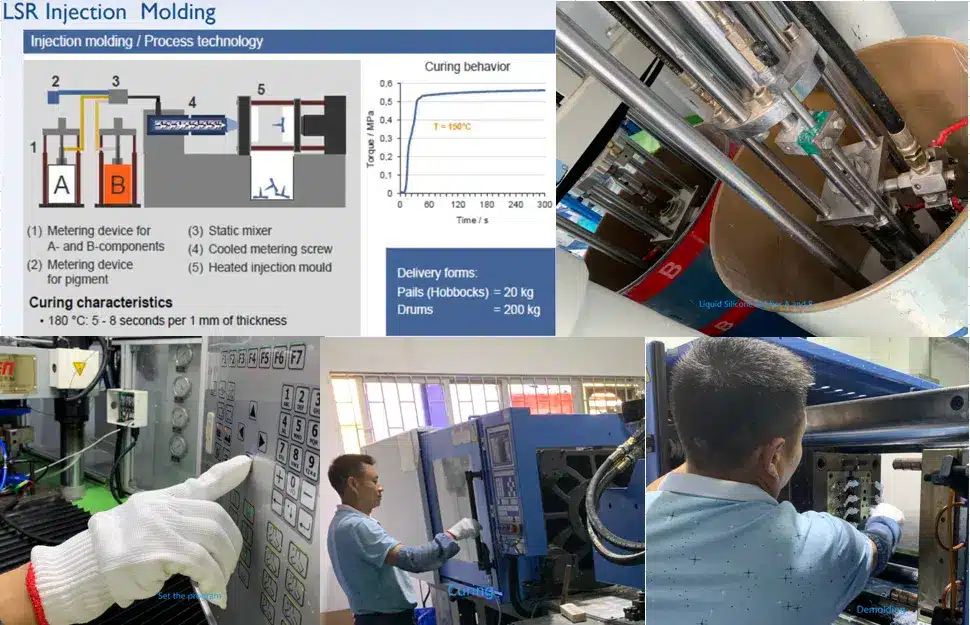

Production Process

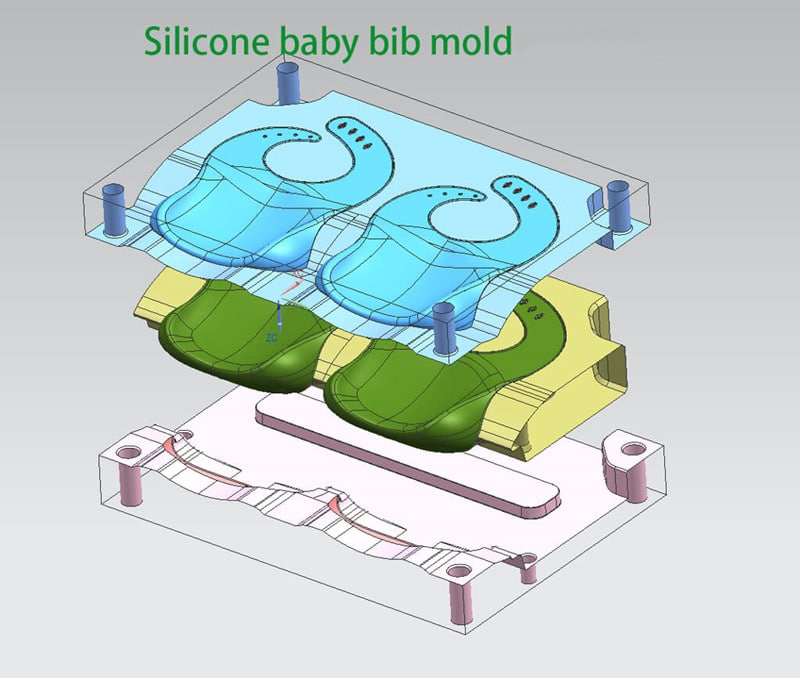

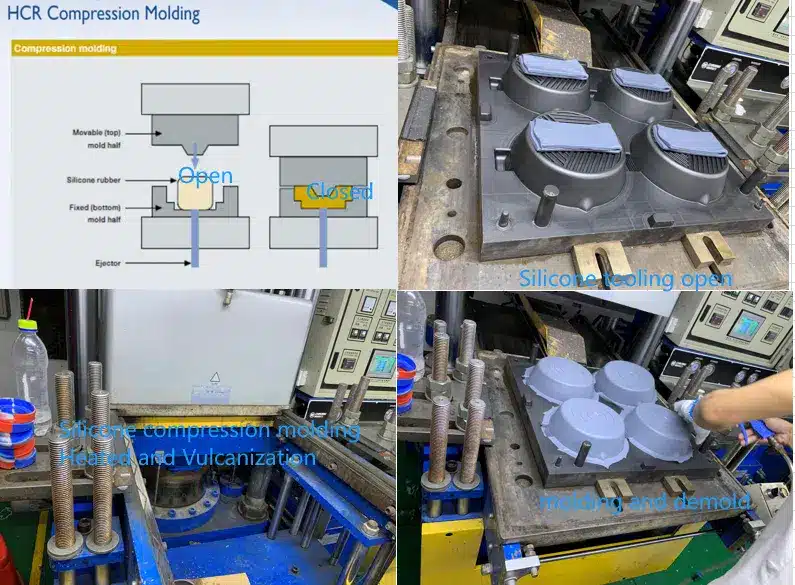

Mold Production: Precision molds are produced through CNC machining based on product design requirements to ensure the accuracy and consistency of the molded parts.

Injection molding: Molten silicone is injected into a mold and cooled to form the mold. The injection temperature and pressure must be strictly controlled to ensure structural stability.

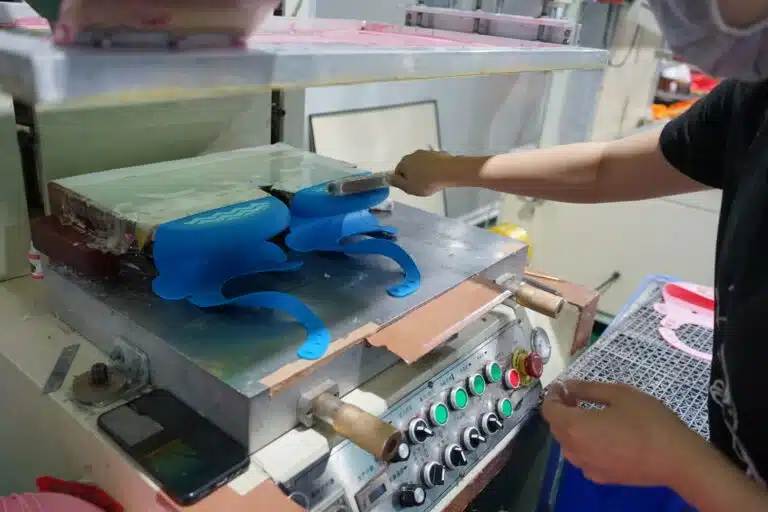

Surface treatment: Use environmentally friendly water-based paint to print patterns or instructions, and achieve detailed processing through silk screen printing, pad printing and other technologies.

Safety and Compliance

Products must comply with EU ROHS and REACH certifications and pass toy safety standards such as CE and EN71.

JUTION is a one-stop custom silicone product manufacturer and silicone molding solutions provider specializing in silicone products. If you would like custom silicone products, please contact us.

How to choose a suitable silicone baby sensory ball?

Safety:

Silicone sensor balls come into direct contact with skin and may even be ingested, so they must pass the China 3C certification or the EU EN71 standard to ensure they are non-toxic and harmless.

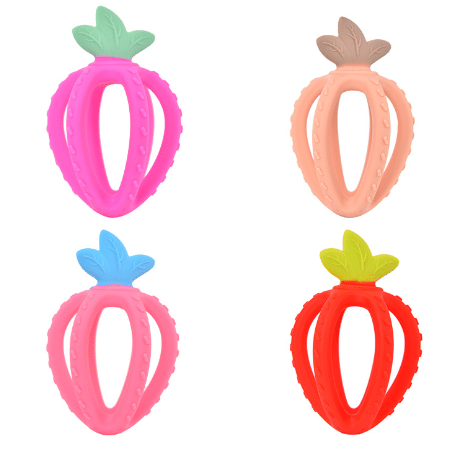

Texture and Shape:

Choose silicone sensor balls with raised dots, grooves, or geometric shapes. These multi-textured surfaces can stimulate the development of nerves in your baby’s fingertips.

Size:

The recommended diameter is 5-8cm, which is in line with the baby’s hand grasping curve, avoiding the risk of swallowing due to being too small or difficult to control due to being too large.

Cleanliness and Durability:

Prefer silicone sensor balls with one-piece or removable designs to reduce the chances of dirt and dirt accumulating in gaps.

JUTION provides comprehensive support from conception to market, making it a preferred partner for leading silicone product brands and retailers.

How to control the quality of silicone baby sensory balls?

Raw Material Quality Control

Supplier Audit: Select suppliers that have passed ISO 10993 biocompatibility testing to ensure that raw materials meet medical-grade standards.

Incoming Inspection: Inspection items include appearance (color uniformity), hardness (±2 Shore A), tensile strength, aging resistance, and microbiological indicators (medical-grade materials require specific testing)

Storage Management: Warehouses must be dry and protected from light, and a first-in, first-out (FIFO) principle must be implemented to prevent raw materials from becoming damp or being stored beyond their expiration date.

Production Process Optimization

Formula Design: Formulas are designed based on product characteristics to ensure stable raw material compatibility, processing temperature, and curing time.

Molding Process: Injection molding requires precise control of pressure, temperature (160-180°C), and speed to avoid bubbles and deformation.

Compression molding requires optimization of mold venting design (0.5-1 venting slots per square centimeter) and preheating parameters.

Post-Processing

Strict cleaning, drying, and vulcanization treatments enhance product durability and safety.

Cleanliness and Equipment Management

The production environment must meet Class 10,000 cleanliness standards. Mixing equipment utilizes an internal mixer with a temperature limit (≤50°C) to minimize the risk of impurities.

How to use the silicone baby sensory balls correctly?

(1) Touch Massage

After bathing or when your baby is feeling well, use a sensory ball to massage your baby.

Different touch points can effectively stimulate your baby’s body, allowing them to perceive the world more quickly and enhancing the parent-child relationship.

(2) Grip Practice

Place the tactile ball in your baby’s hands and let them grip it naturally, feeling the ball’s elasticity and surface texture.

This helps develop fine motor skills and strength, and promotes muscle development.

(3) Tactile Perception Games

Place tactile balls of different textures in a bag and have your child touch them. Then describe the feeling, such as “it’s granular” or “it’s smooth,” to stimulate tactile perception and develop language skills.

(4) Early Childhood Education Games

Roll the tactile balls and have your baby reach out to grab them, developing hand-eye coordination and reflexes.

Cover the tactile balls with a cloth and have your baby play hide-and-seek.

Play throwing games with the tactile balls to develop fine motor skills and hand-eye coordination.

How to clean and maintain the silicone baby sensory balls?

Keep baby toys clean to prevent bacterial growth.

Before and after each use, remember to clean the surface of the ball with a mild dish soap and a sponge or soft cloth.

Rinse the silicone sensor ball with warm water to remove dust and dirt, especially around the edges and details.

Ensure it is thoroughly clean. (Do not scrub with a hard brush or steel wool, as this may scratch the silicone surface.)

After cleaning, gently wipe the surface of the sensor ball with a rag to ensure no water stains remain.

After cleaning, avoid storing silicone baby sensor balls in a humid environment. Store them in a dry, cool place away from direct sunlight or high temperatures to prevent degradation of the silicone.

Conclusion

Sensory training is actually very simple. This silicone sensory ball can not only be used as a toy, but also can be used for sensory training and motor development for babies, allowing them to have freedom and explore independently while playing. Scientific selection of silicone baby sensory balls is the key, and quality and safety are the foundation. Choose the right style according to the baby’s age and development stage. Correct use and guidance can maximize the product value and development effect. Let us use silicone baby sensory balls to accompany our children’s growth!