Essential for sensory development Silicone baby sensory toys

As an expert who has been deeply engaged in the field of silicone materials for many years, I have witnessed how this extraordinary material has moved from industrial applications to key areas that promote human development. Today, I would like to discuss with you an important topic related to a child’s lifelong development-sensory development. In the early stages of infant growth, the development of the sensory system is a key factor affecting the baby’s brain cognition, motor coordination and emotional regulation. Compared with wooden or plastic early childhood auxiliary toys, silicone sensory toys are safe and soft. Not only can it allow babies to obtain tactile feedback through biting, pinching, grabbing, pressing and other actions, but it can also promote the baby’s sensory development through color, shape and sound. This article mainly introduces the definition of silicone sensory toys, its applicable population and scenarios, the reasons why infants and young children need such toys, as well as precautions and cleaning methods when purchasing.

If you are interested in silicone sensory toys or want to know more about them, please read this article.

What is a silicone sensory toy?

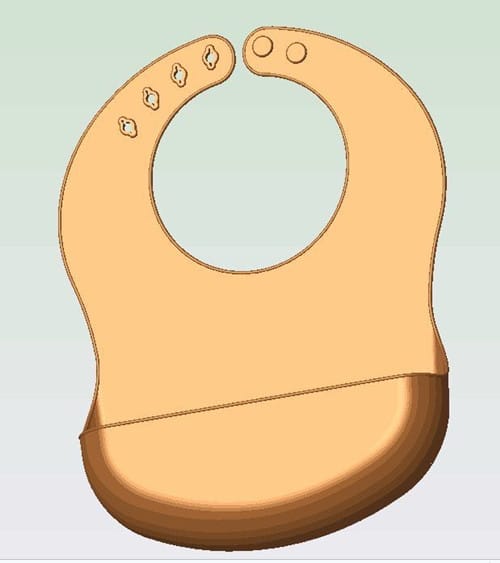

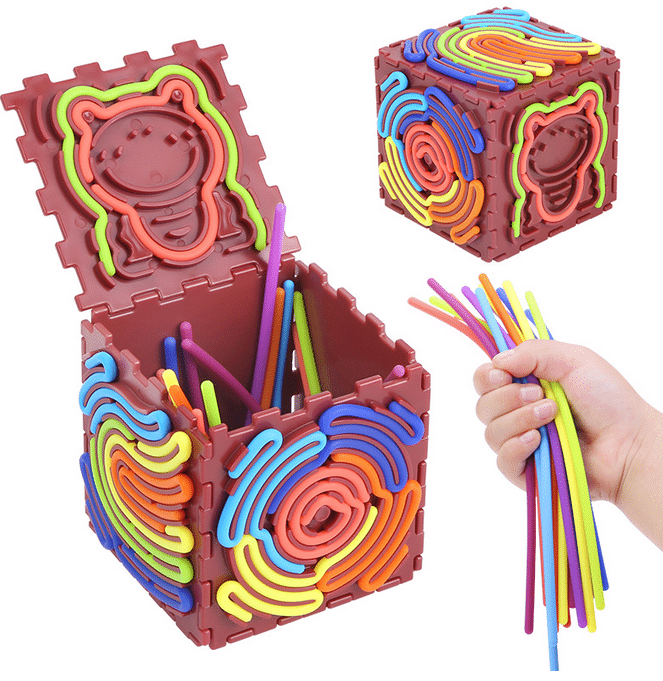

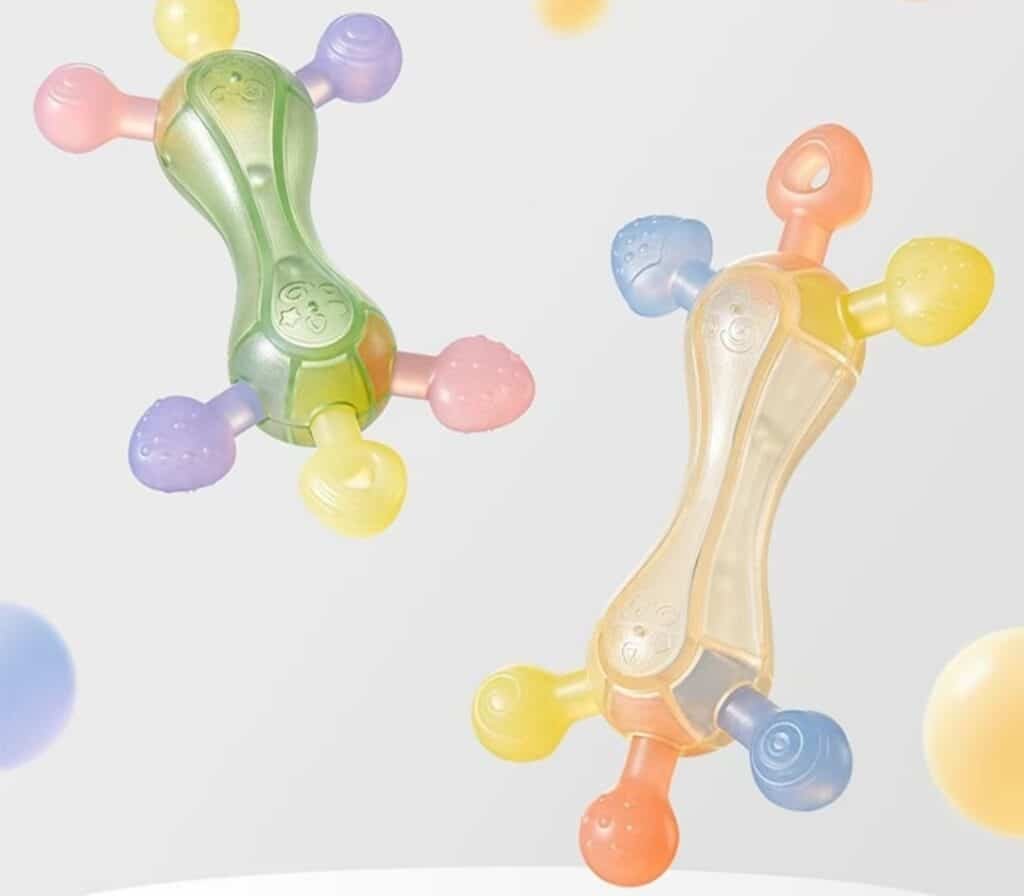

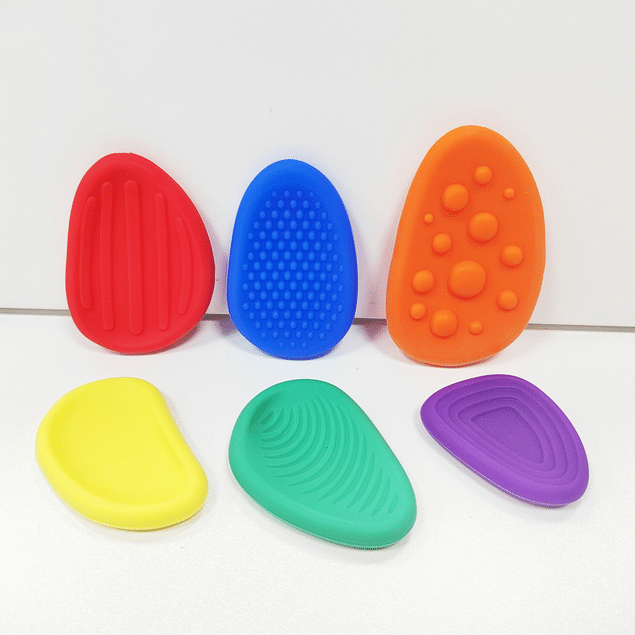

Silicone sensory toys are made of food-grade silicone material. They are soft and elastic, comfortable to the touch, non-toxic, resistant to high and low temperatures, and highly insulated and chemically inert, making them particularly suitable for infants and young children. Through carefully designed textures, shapes, and colors, silicone sensory toys provide multiple stimulations of vision, touch, proprioception, and vestibular senses, promoting the development of neural pathways and the integration of brain information.

Why are silicone sensory toys necessary?

If you would like to learn more about silicone products, please contact us at JUTION.

Whom is the silicone sensory toy most suitable?

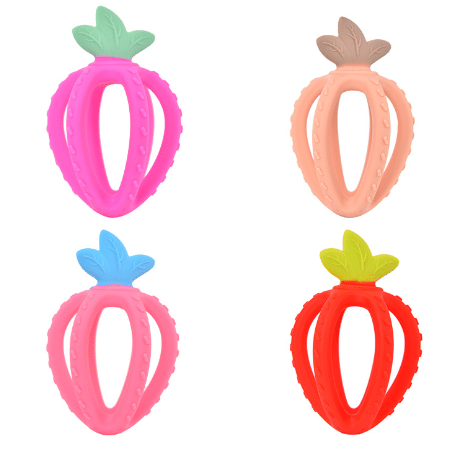

For babies in the oral and teething stages:

Silicone sensory toys are soft, non-toxic, and suitable for babies to grasp, chew, and play with. They can satisfy oral needs, relieve teething discomfort, and enhance perception and hand-eye coordination.

For babies with sensory impairments:

Such as visual or hearing impairments, silicone sensory toys can help them better perceive the world around them through different shapes, textures, and materials, enriching their sensory experience.

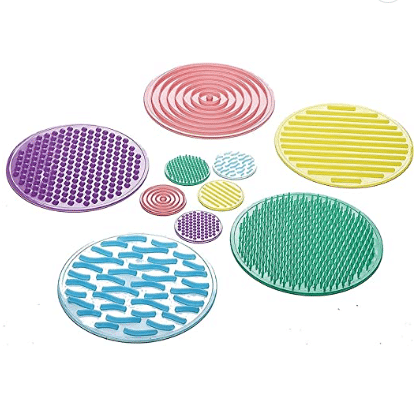

For babies in the critical period of visual and tactile development:

Silicone sensory toys have natural colors and cute shapes, which can attract the baby’s attention and stimulate visual development; its soft texture and different textures and shapes on the surface can allow the baby to experience different tactile experiences and promote tactile development.

When is the silicone sensory toys most suitable to be used?

During daily playtime: When your baby is awake and in a good mood, silicone sensory toys can be used in the crib, on the living room floor, or outdoors. These toys help develop grasping, shaking, throwing, and other movements, improving hand-eye coordination and muscle strength.

Outdoors: When your baby is fussy, crying, or otherwise upset, portable silicone sensory toys can provide some emotional comfort. By touching and grasping these toys, your baby can gain a sense of security and satisfaction, helping to stabilize their mood.

Where are silicone sensory toys suitable for use?

If you want to customize unique silicone products, you can contact us JUTION, we will provide you with the most loyal service and the most affordable price.

How are silicone sensory toys produced?

Material Preparation

Medical-grade platinum-cured silicone is used, with molecular structure manipulation to achieve varying hardness, elasticity, and surface properties to meet diverse sensory stimulation needs.

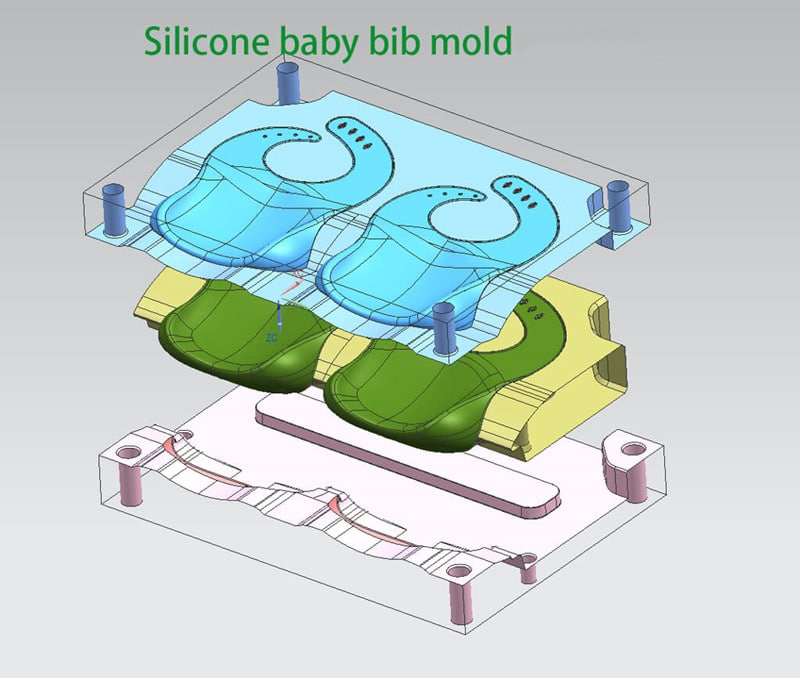

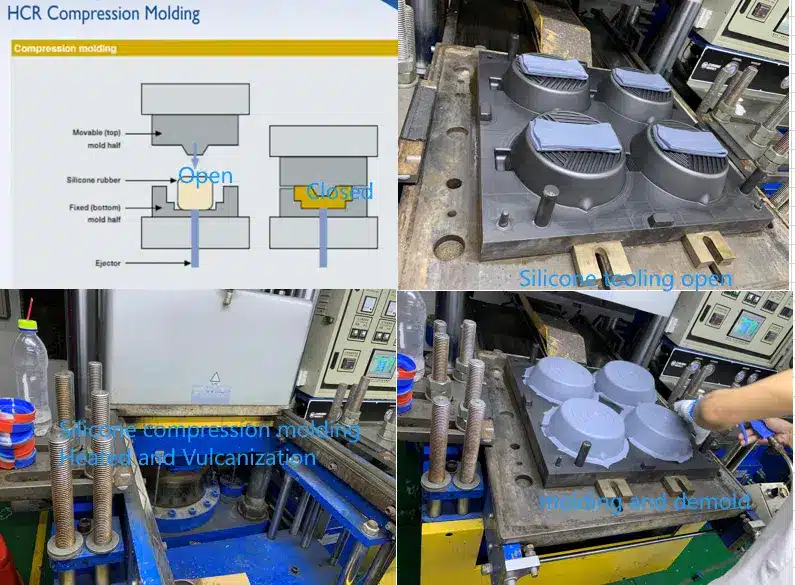

Mold Production

High-precision molds are produced using CNC machine tools. Based on scientific research on infant hand size and grip development, the ergonomic shape and dimensions are designed to ensure product dimensional accuracy. The mold is designed with multiple cavities to improve production efficiency, and vent holes are provided to prevent air bubbles during molding.

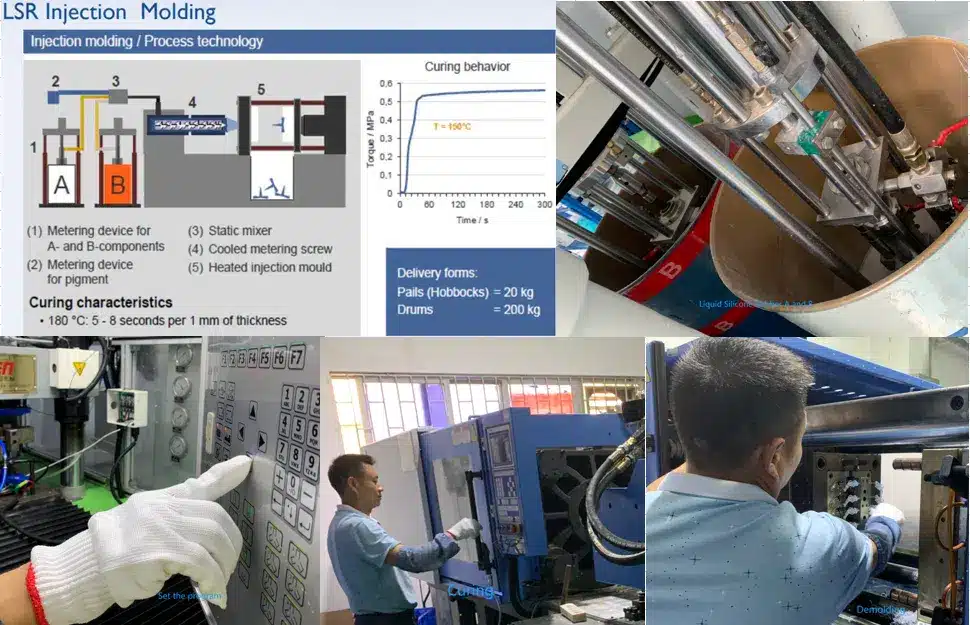

Molding Process

Infusion Molding: The formulated silicone is vacuum-degassed and poured into a mold, where it is allowed to cure by standing or heating.

Injection Molding: High temperature and pressure are used to fully penetrate the silicone into the mold, forming the initial shape of each component.

Color Science: High-contrast color combinations supported by visual development research are used to promote the development of visual pathways.

Texture Engineering: Precision mold processing techniques are used to create a variety of scientifically validated surface textures, ranging from smooth to varying degrees of roughness.

Demolding After Curing

Carefully remove the mold after curing to avoid damaging the molded structure.

We JUTION is a one-stop customized silicone product manufacturer and silicone molding solution provider specializing in the field of silicone products. If you need customized silicone products, please contact us JUTION.

How to purchase the right silicone sensory toys?

- Details:

- Children’s silicone sensory toys should have a smooth surface and rounded edges to avoid scratching children’s skin during use.

- Color and Design:

- Children’s silicone sensory toys with cute shapes and bright colors may be your first choice, but the colors should be safe and ensure they do not pose a risk to your baby’s health.

- Size:

- The size of children’s silicone sensory toys should be moderate to avoid affecting the baby’s use effect due to being too large or too small.

How to control the quality of silicone sensory toys?

Raw Material Quality Control

Each batch of raw materials is tested for indicators such as volatile matter (≤0.5%), hardness deviation (±2 Shore A), and Mooney viscosity (40-60 MU). Food-grade and medical-grade materials also require FDA/LFGB certification and microbiological testing.

Production Process Control

Formulas are designed based on product requirements, taking into account raw material compatibility, processing temperature, and curing time to ensure repeatability.

Molding Process

Mold Temperature: Solid silicone 160-180°C, liquid silicone 170-210°C

Venting Design: 0.5-1 vent grooves (0.03-0.05 mm deep) are provided per square centimeter.

Vulcanization Monitoring: A PLC system is used to track temperature (±2°C), pressure (8-15 MPa), and time (t90 + 10%) in real time. Medical-grade products require a step-by-step temperature ramp.

Finished Product Testing and Safety Assessment

Physical Properties: Tensile strength ≥3 MPa, tear strength ≥10 kN/m, and compression set ≤20% to ensure durability.

Sensory Safety: The surface is odorless and meets VOC safety standards, preventing the migration of harmful substances such as formaldehyde and benzene.

Biological Safety: Passed skin irritation and sensitization testing (ISO 10993 standard) to ensure no allergic risk.

Environmental and Equipment Management

Production workshops must meet ISO Class 7 cleanliness standards, with humidity controlled between 40% and 60%. Electronic equipment must be protected against static electricity to minimize the impact of impurities and contamination on products.

The silicone products produced by our JUTION are suitable for various industries such as consumer goods, industrial products and medical treatment. They are of good quality and you can rest assured to contact us for customization.

How to clean and maintain silicone sensory toys?

- Warm water cleaning: First, roughly clean the silicone toy; then, soak the toy in warm water with a small amount of neutral detergent, and gently scrub it with a soft brush to remove surface stains and dirt; finally, rinse it with clean water and dry it with a clean towel.

- Vinegar and water soaking cleaning: Mix a certain proportion of vinegar and water, soak the silicone toy in the mixed water for about 10 minutes; then rinse with clean water and wipe dry with a clean towel or dry it.

- Wipe with disinfectant wipes: Use children’s disinfectant wipes to wipe the surface of the silicone toy directly to remove surface stains and rinse with clean water after wiping.

Conclusion

Silicone baby sensory toys are not just toys, but also important tools for babies to explore the world, develop their senses, and train their brains. Infancy is a critical period for sensory development. Silicone sensory toys can help your baby learn through play and promote their understanding of the world through grasping and biting. Using sensory toys to stimulate sensory development helps children grow better.