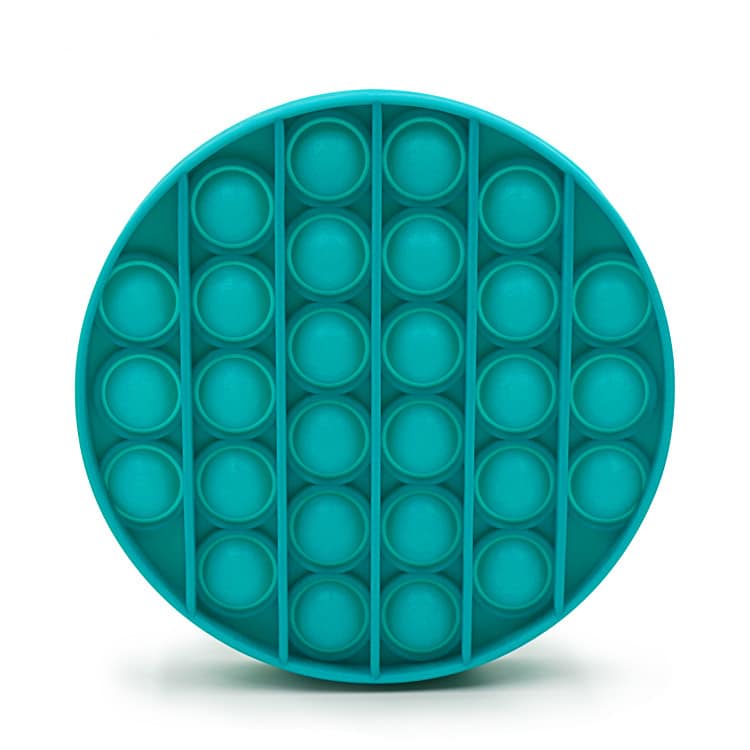

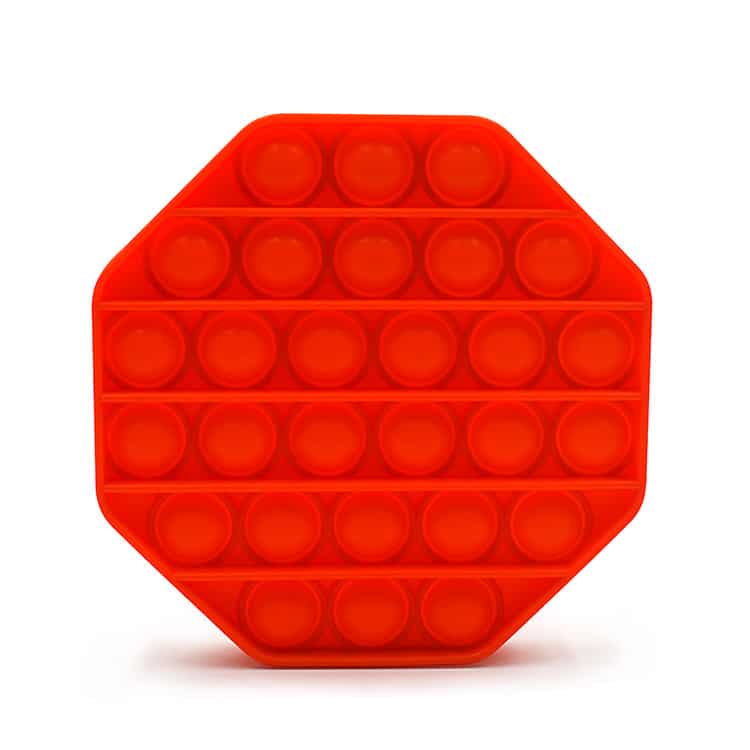

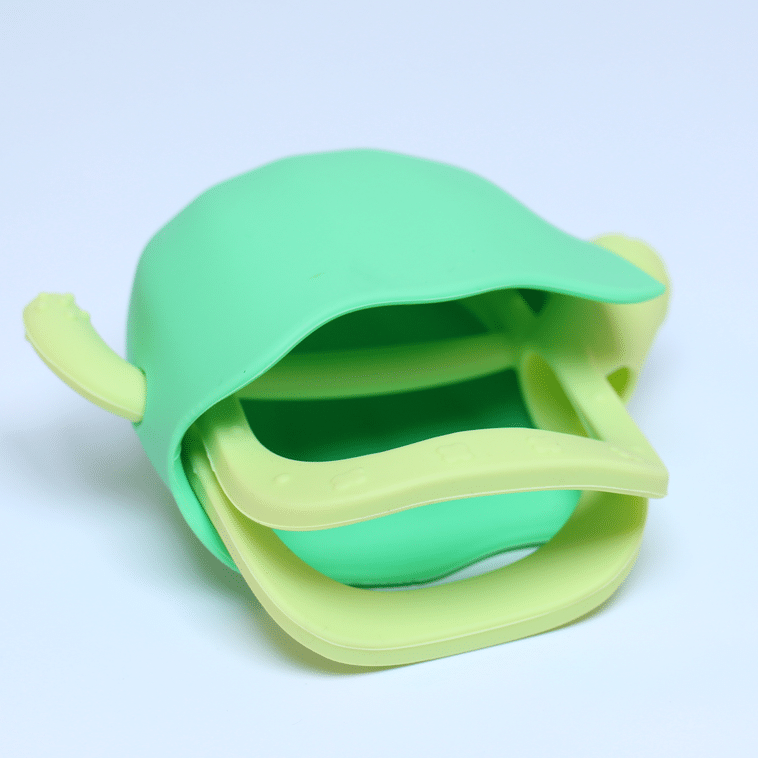

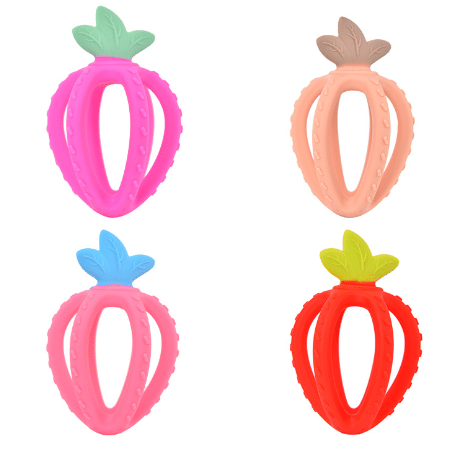

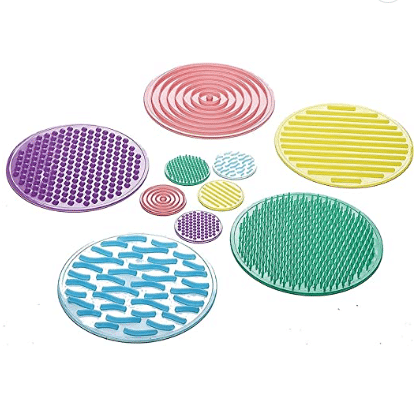

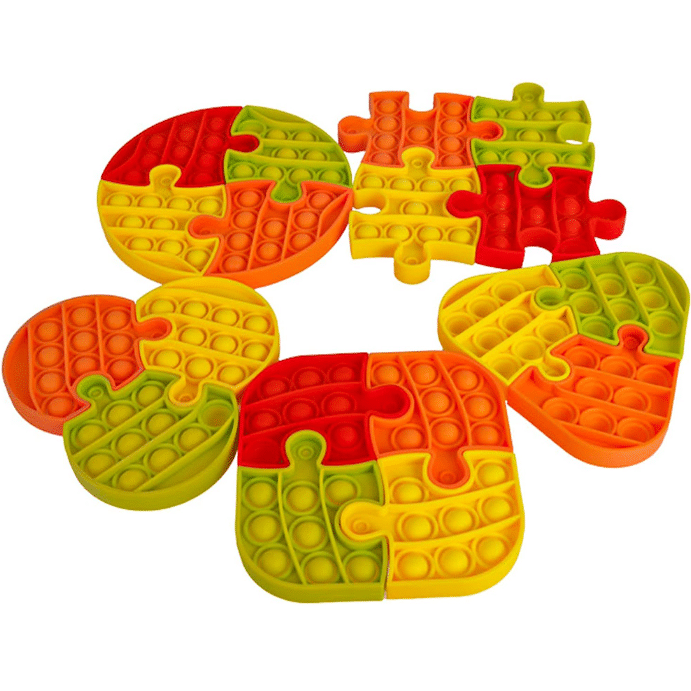

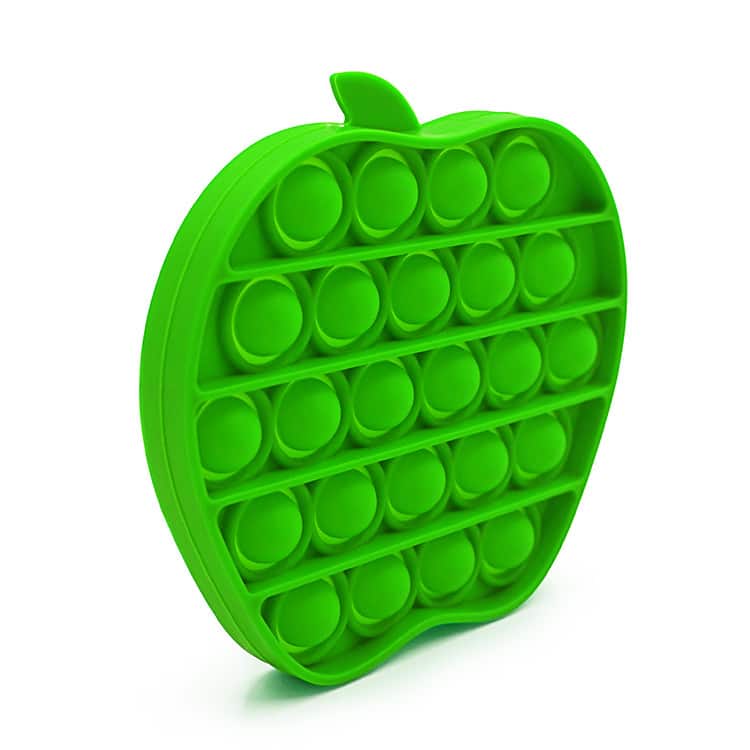

Custom Silicone bubble poppers

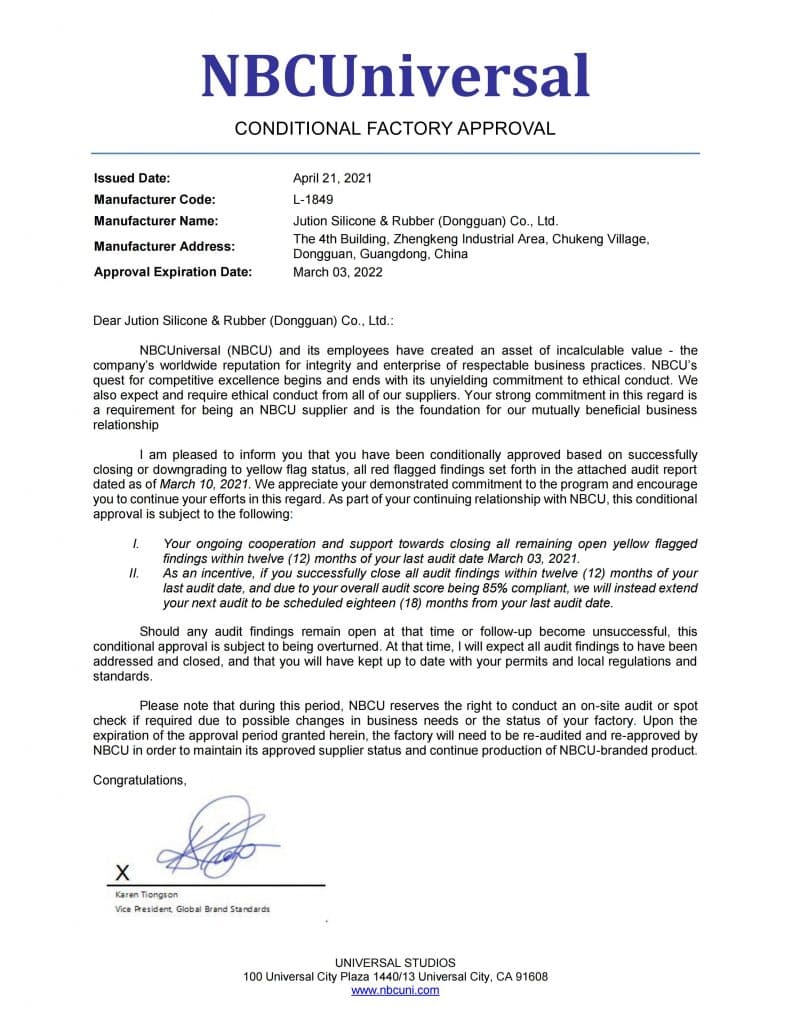

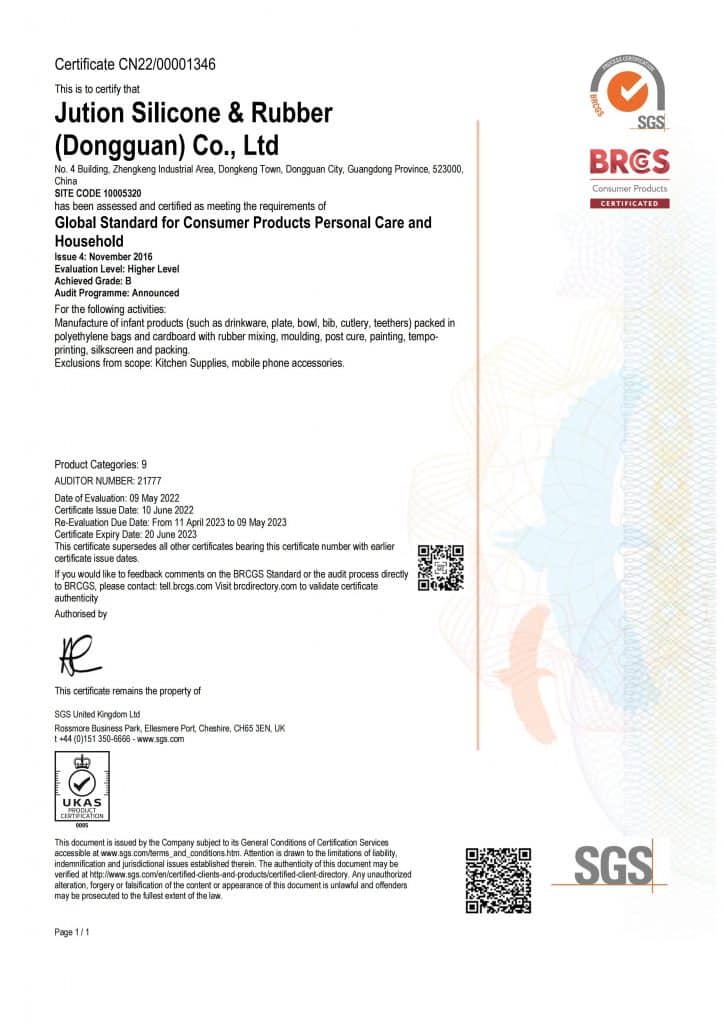

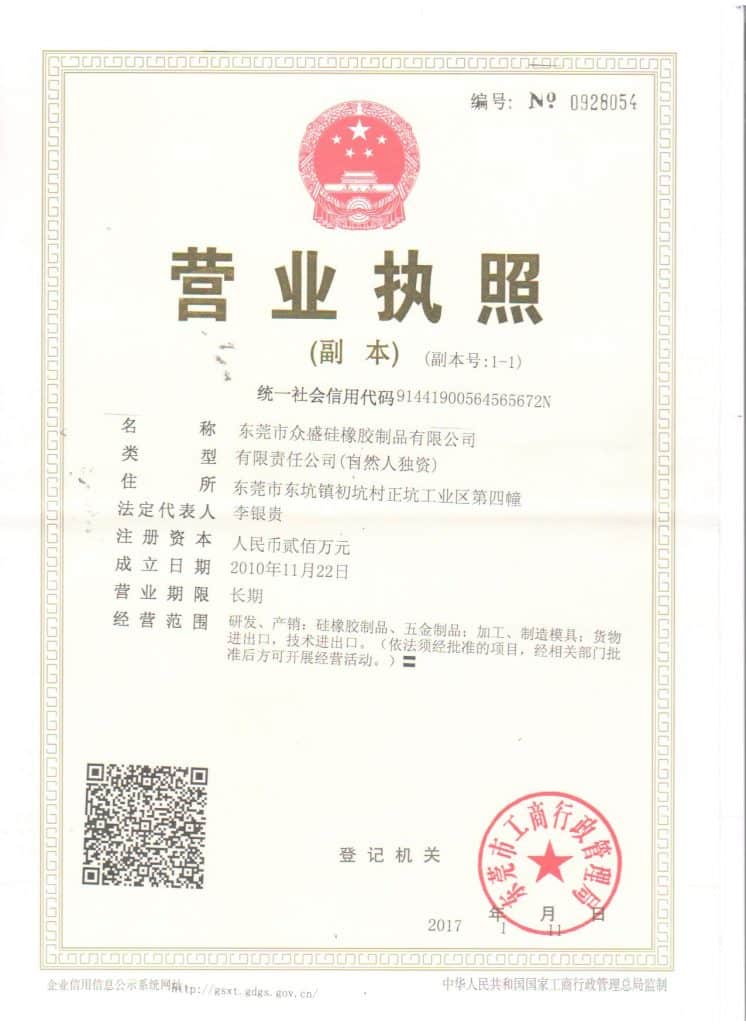

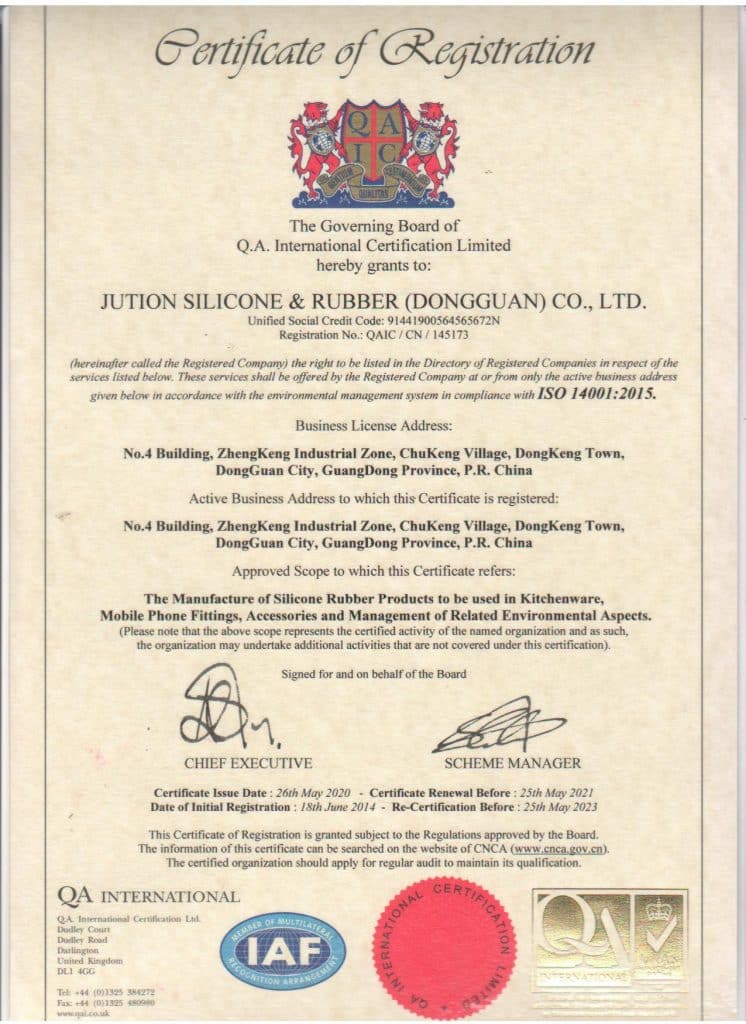

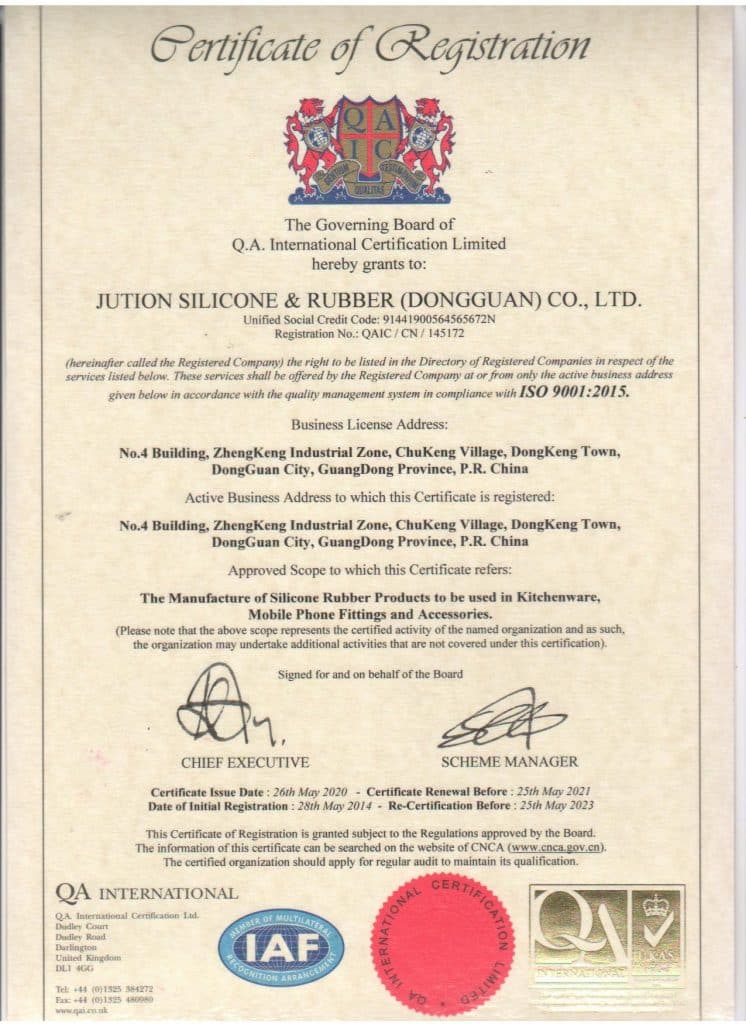

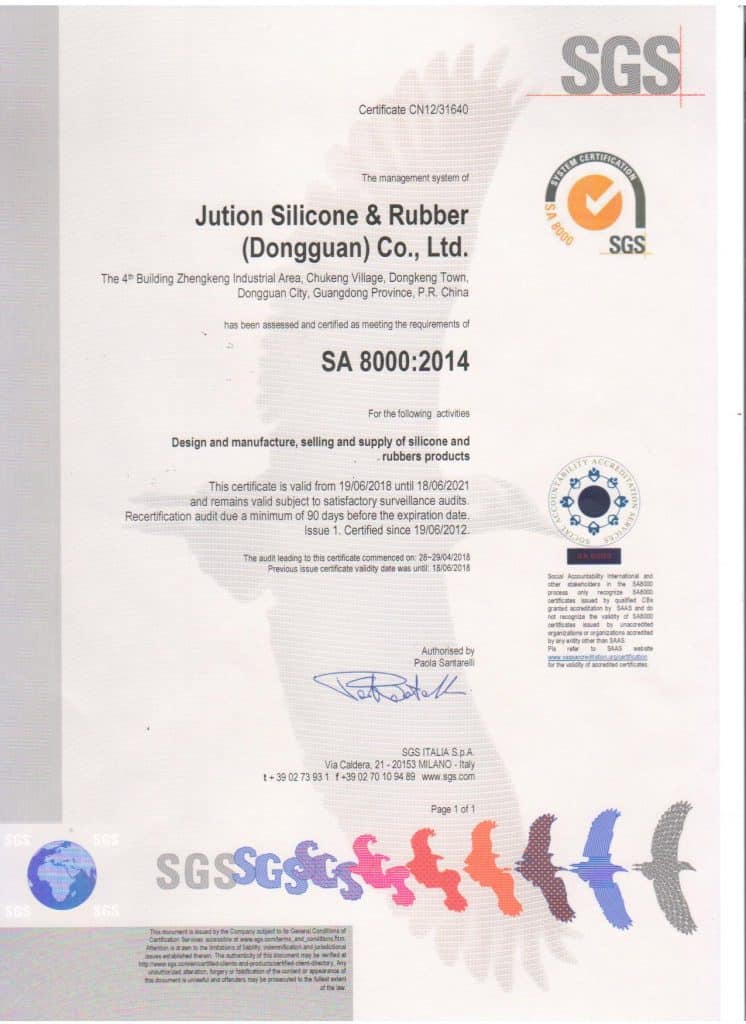

Jution Silicone is a China Silicone bubble poppers-making factory for baby Industry. We help the baby and kids industry make customized silicone baby care and accessories products. mainly engaged in the manufacture and wholesale of silicone baby products.

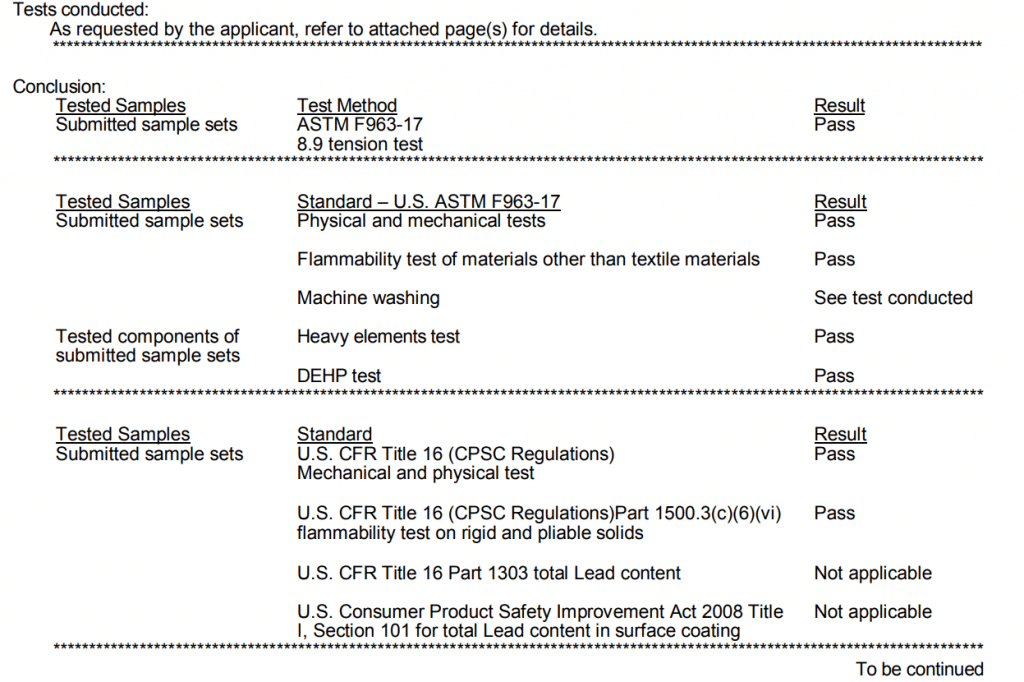

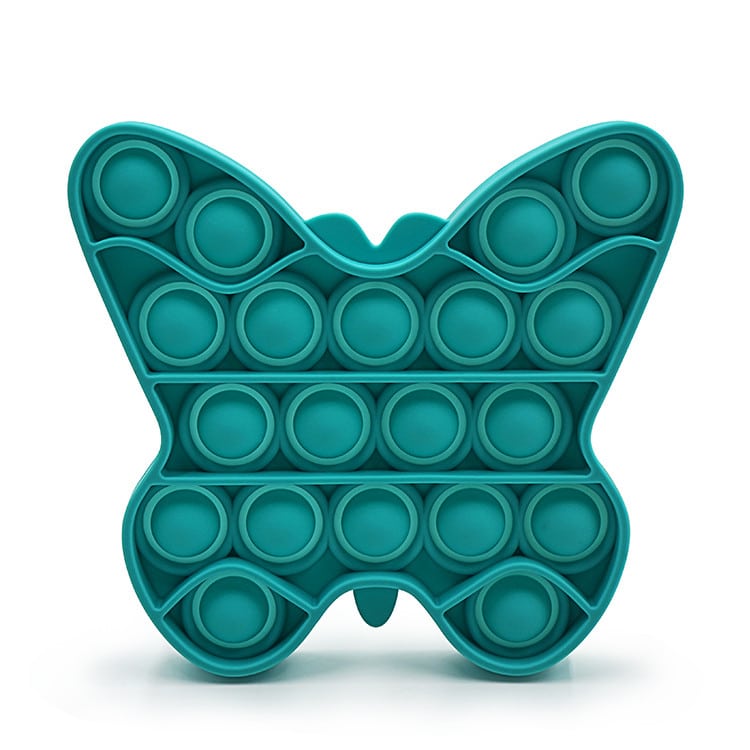

Silicone bubble poppers – They are perfect for kids & adults to have endless fun while relieving stress & anxiety. That’s why our bubble sensory toys have both sides designed to pop, imitating the pleasant bubble wrap sound & volume perfectly

Features

Specification

Description

Jution Silicone has more than 30 compression molding production machines and 22 hours of mass production of silicone stacking toy. At the same time, there is a strict product quality control system to ensure the silicone stacking toy quality. We provide you with different wholesale funny silicone stacking toy, cute patterns, and colorful colors to make wholesale silicone stacking toy more fashionable and make baby feeding fun.

Jution Silicone has a professional design team, from design to mold making, we provide comprehensive OEM&ODM services for your silicone stacking toy.

Gallery

Shipping

For the Silicone baby bibs you can choose the shipping:

- Sea shipping, 35-50 days

- Air shipping, 10-15 days

- Express(DHL, UPS, TNT, FedEx etc.) 3-7 days

- All the silicone baby bibs can be returned in their original condition for a full refund or replacement within 30 days of receipt with clients pay the shipping cost.