silicone baby bib – Waterproof bib for babies when eatin

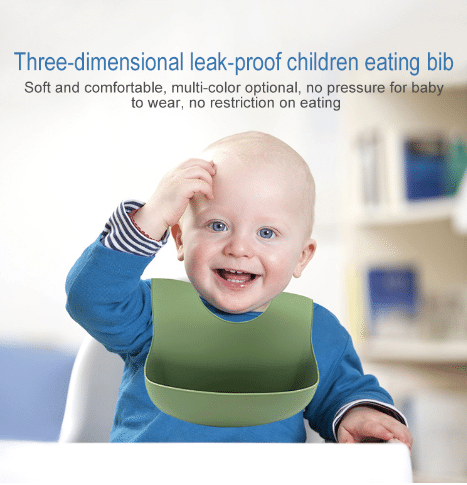

As a senior practitioner who has been deeply involved in the silicone industry for many years, I have witnessed the iterative upgrades of countless maternal and child products over the years, but few products can combine practicality, safety and aesthetics so perfectly as food-grade silicone bibs. When babies learn to eat independently, the eating process is often accompanied by scenes of “spillage, dropping, smearing, and overflowing”. Against this background, waterproof and oil-proof silicone baby bibs have gradually become a must-have choice for new parents, greatly reducing the burden of cleaning. This article mainly introduces the definition and target users of silicone baby bibs, the reasons why infants and young children need it and the specific applicable time, as well as precautions when purchasing and using it.

If you are interested in silicone baby bibs or want to know more about them, please read this article.

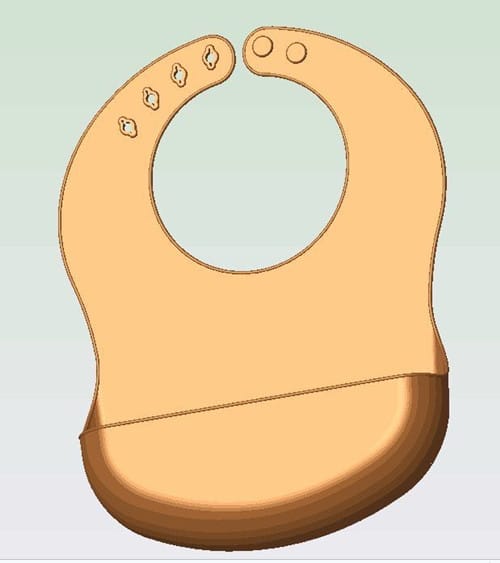

What is a silicone bib?

Silicone bibs are made of food-grade silicone.

They are soft, durable, waterproof and oil-proof.

Compared with traditional cloth or plastic bibs, food-grade silicone bibs are more environmentally friendly, safer, and easy to clean and maintain.

They are a key tool for babies to transition from feeding to self-feeding, integrating food collection, convenient cleaning, and feeding training.

Why is the silicone bib necessary?

Cloth bibs: They are softer and more comfortable for babies, but they lack water resistance, requiring frequent cleaning, which takes up a lot of work or personal time.

Plastic bibs: They are more resistant to water and oil, but they are heavier, which can negatively impact a baby’s neck. Some plastic bibs also pose safety risks.

Compared to plastic and cloth bibs, which have certain drawbacks, silicone bibs are water-resistant and stain-resistant, effectively preventing food and liquids from penetrating, protecting baby’s clothing. Food-grade silicone is safe and non-toxic, harmless to baby’s health. Silicone bibs have a smooth surface and are easy to clean, either by rinsing or in the dishwasher. Thanks to food-grade silicone bibs, baby’s health and safety are guaranteed, and parents can enjoy a relaxing time.

Who are the main target users of the silicone bibs?

New parents:

Safe, non-toxic, food-grade silicone bibs are waterproof and dirt-repellent, effectively protecting baby’s clothing from food and saliva stains, reducing the cleaning burden for parents. Additionally, some silicone bibs are adjustable, allowing for easy movement without feeling restrictive.

Early childhood education centers and nurseries:

As places where large numbers of children gather, cleaning tables and floors after group meals is a significant task, requiring a large supply of silicone bibs to minimize the risk of food residue.

Gift purchase:

Silicone bibs are soft, comfortable and safe. You can customize silicone bibs of different styles and shapes here. They are beautifully packaged and both practical and decorative. They are the first choice for gifts for families with babies.

If you want to customize silicone products with good quality and affordable prices, you can contact us JUTION.

When is it appropriate to use a silicone bib?

Before and After Teeth Eruption: When baby teeth erupt, swollen gums stimulate the oral nerves to secrete saliva, causing many babies’ mouths to act like “faucets.” Silicone bibs can prevent saliva from reaching the delicate neck and preventing skin problems.

During Meals: Silicone bibs can effectively prevent food, soup, and other liquids from splashing onto baby’s clothes, reducing the amount of cleaning for parents and keeping baby’s clothes clean and tidy. They are also convenient for daily use.

When playing outdoors or indoors: It is normal for babies to spill sand and paint all over their bodies when playing with sand and painting. Wearing a silicone bib can minimize the chance of dirtying the baby’s clothes.

Where is it appropriate to use a silicone bib?

How to produce silicone bibs?

Raw Material Preparation

Use food-grade liquid silicone or solid silicone raw materials. Add curing agents, color pastes, and other auxiliary materials according to the formula to ensure they are non-toxic, environmentally friendly, and meet high-temperature sterilization requirements.

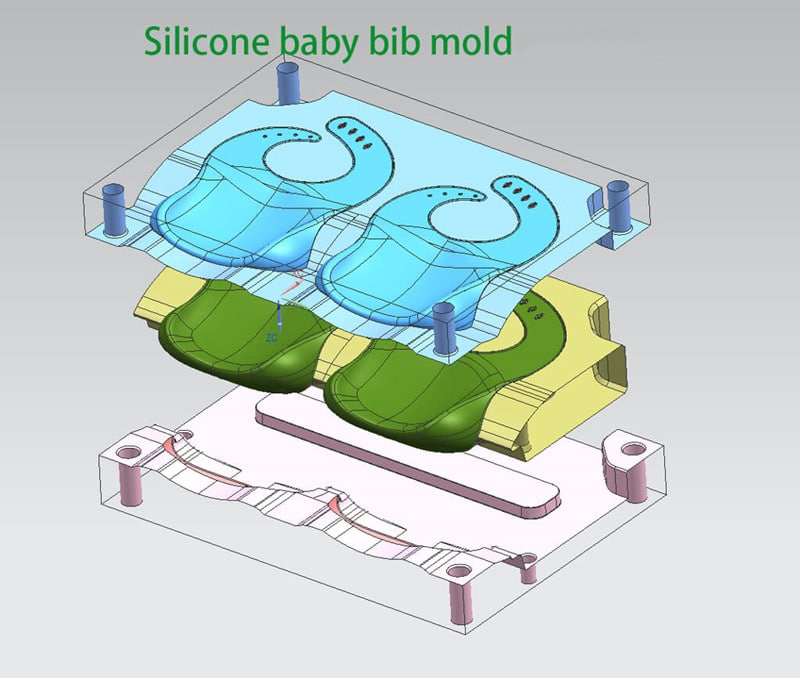

Mold Making

Based on the product’s shape and size requirements, the mold is precisely machined using CNC machines. The bib’s curved design, adjustable buckle positions, and folding features are taken into consideration to ensure dimensional accuracy after molding.

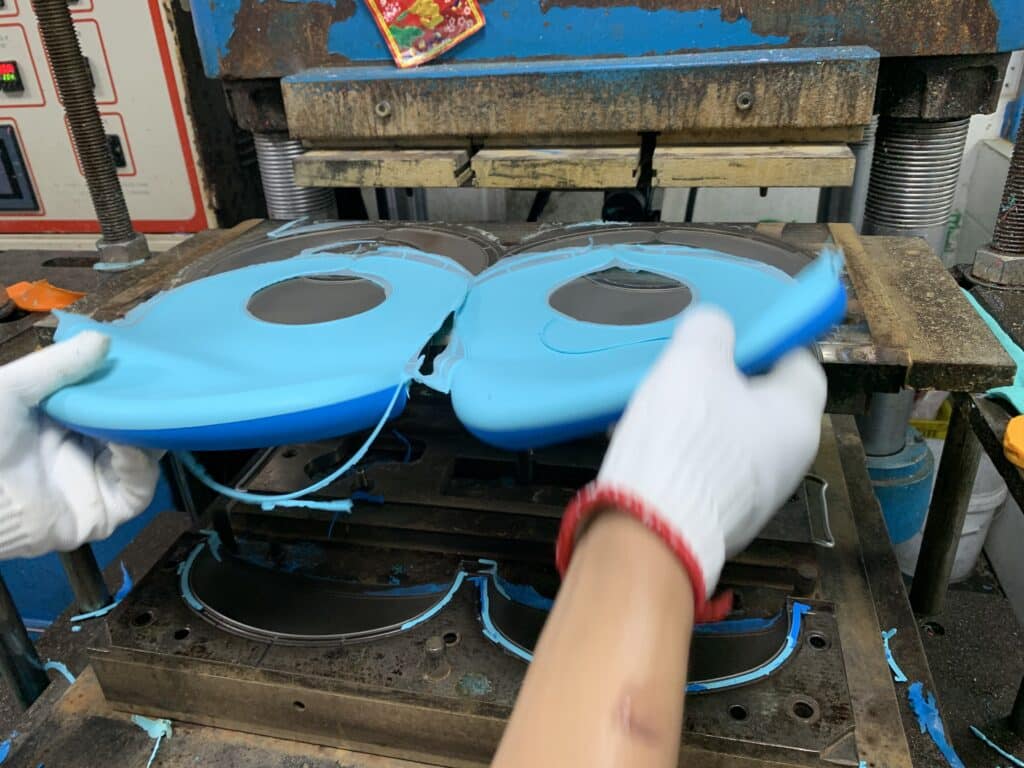

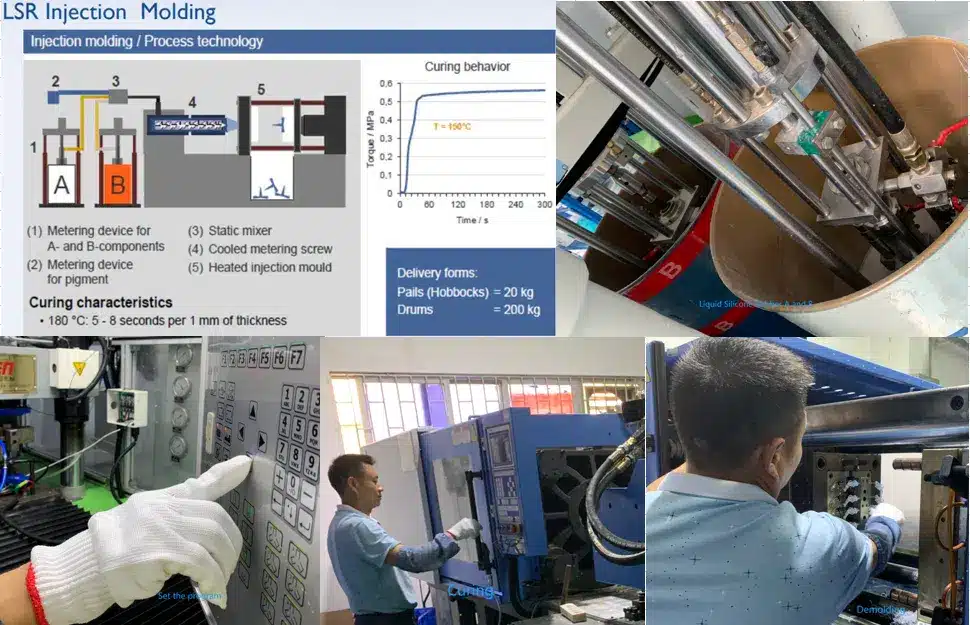

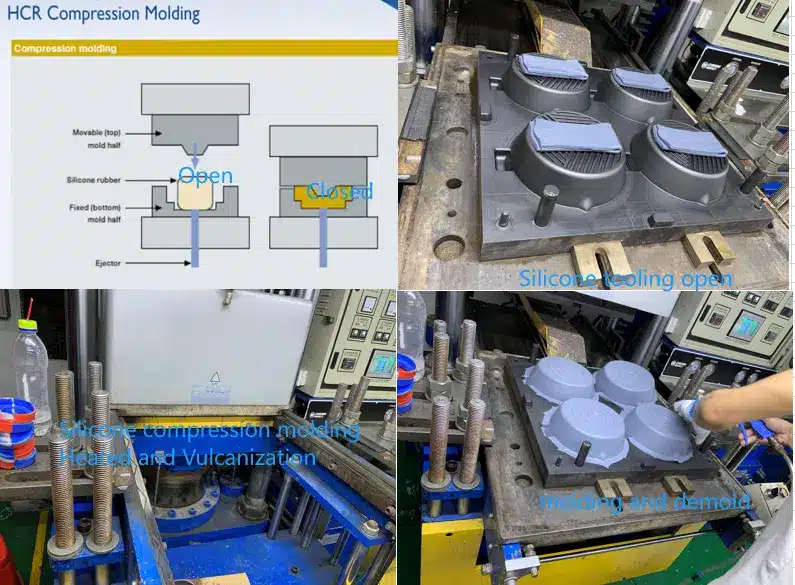

Vulcanization Molding

The raw material is poured into the mold and molded in a vulcanizer at high temperature (170±2°C) and pressure (15-25MPa). The molding time is calculated based on the thickness (1.5 minutes per millimeter). Strict temperature control is required to ensure uniform vulcanization of the product.

Post-processing and testing

After molding, burrs must be removed, a food-grade release agent sprayed on, and the dimensional accuracy (error ≤ ±0.005mm) inspected using a projector. Surface smoothness and the absence of residual particles are also checked.

We, JUTION, are a one-stop custom silicone product manufacturer and silicone molding solution provider specializing in the field of silicone products. If you want to know more about silicone products, please contact us.

How to purchase the right silicone bibs?

Quality Assurance: When purchasing silicone bibs for your baby, be sure to check the product’s relevant certifications and logos to choose a brand with reliable quality.

Colors and Styles: Silicone bibs come in a variety of styles and designs on the market. Your baby’s interests and preferences are key considerations when choosing.

Adjustable Design: Some silicone bibs feature an adjustable neck strap, making it suitable for babies of different ages and easily adjustable to suit their neck size.

Easy to Carry: A soft, lightweight, and easy-to-carry bib is a must-have for most parents when taking their baby out.

How to control the quality of silicone bibs?

Raw Material Quality Control

Raw Rubber Screening: High-purity raw rubber is selected and tested for indicators such as volatile matter (≤0.5%), hardness deviation (±2 Shore A), and Mooney viscosity (40-60 MU) to ensure stable basic performance.

Additive Proportioning: High-precision feeders are used to control the masterbatch addition error to ≤0.3%. The anti-yellowing agent addition ratio is controlled at 0.5%-1.2%. If the flame retardant content exceeds 40%, a coupling agent is required to prevent performance degradation.

Mixing Process Parameters

Internal Mixer Settings: Initial temperature 20-25°C, mixing time 8-12 minutes, discharge temperature ≤ 50°C, Mooney viscosity fluctuation controlled within ±3 MU.

Open Mixer Operation: Thin passes ≥ 6 times, roller gap adjusted to 0.5-1 mm to eliminate undispersed particles.

Compound Curing: Allow to stand in a constant temperature room at 25°C for at least 24 hours. Medical-grade products require curing in a Class 10,000 cleanroom.

Molding and Vulcanization Control

Mold Design: Proper venting grooves (0.5-1 per square centimeter) with a depth of 0.03-0.05 mm are designed to prevent air bubbles.

Vulcanization Parameters: A PLC system monitors temperature (±2°C), pressure (8-15 MPa), and time (t90 + 10%) in real time. The secondary vulcanization stage requires a 4-hour oven treatment at 200°C.

Environmental and Equipment Management

Cleanliness Control: Medical-grade production workshops must meet ISO Class 7 cleanliness standards and maintain a humidity level of 40%-60% to prevent microbial contamination.

Equipment Maintenance: Regularly calibrate molds and equipment to ensure stable temperature and humidity in the production environment.

JUTION is highly praised for providing innovative custom silicone products, manufacturing expertise and technical solutions. If you need help, please contact us JUTION.

How to use the silicone bibs correctly?

- Ensure the bib is clean:

- Wash the silicone baby bib thoroughly before use to ensure it is free of dust and impurities.

- Adjust the bib size:

- Adjust the size of the silicone baby bib to your baby’s neck size to ensure a comfortable fit.

- Put on the bib:

- Place the silicone baby bib around your baby’s neck, making sure the ears fit snugly around your baby’s neck, then secure the bib at the back of the neck with the buttons.

How to clean silicone bibs?

Soak Cleaning

Prepare warm water (40-50°C) and neutral detergent and soak the bib for 10 minutes to soften the stains (avoid using hot water to prevent deformation or fading)

Gentle scrubbing

Use a soft-bristled brush or cloth to gently scrub the stain, focusing on stubborn dirt like food residue and grease. Avoid applying excessive pressure or scratching the surface with hard objects.

Rinse and dry

Rinse thoroughly with clean water to ensure no detergent residue remains. Hang in a well-ventilated area to air dry, avoiding direct sunlight or high temperatures.

When not in use, store in a cool, dark place. Avoid prolonged exposure to direct sunlight. Keep away from open flames and sharp knives.。

Conclusion

In general, silicone baby bibs have the advantages of being resistant to high and low temperatures, soft and elastic, and have a smooth and easy-to-clean surface. They are designed with ergonomically calculated pocket grooves, are safe and non-toxic, and can provide babies with a comfortable and safe dining experience. They can truly free their hands and enable babies to explore. With the popularization of scientific parenting and environmental protection concepts, silicone baby bibs meet the needs of the public and are a standard feature of every mother-baby family.