Top 10 China Silicone Teethers Manufacturers and suppliers

Are you looking for high-quality silicone teethers or silicone teethers molding solutions provider? The crucial is Finding the right silicone teethers manufacturer. China has established itself as a global leader in silicone teethers production, with companies offering a wide range of the silicone teethers and silicone molding services.

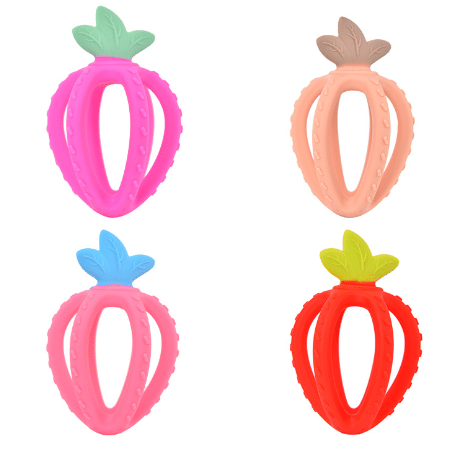

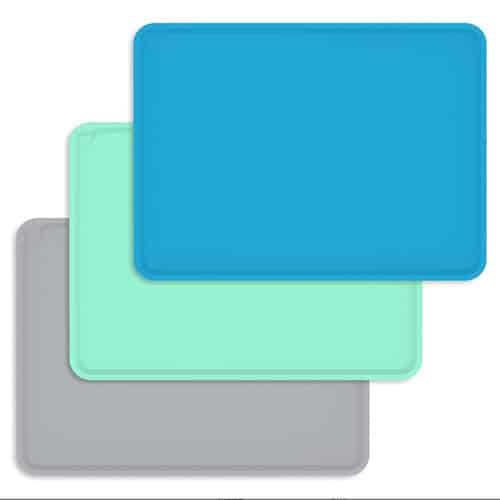

In this article, we delve into the top China silicone teethers molding manufacturers and suppliers, highlighting their strengths and what sets them apart. From silicone placemats to silicone pacifier, these companies provide OEM and ODM durable and ECO silicone teethers solutions for baby industries.

Jution Silicone & Rubber (Dongguan) Co., Ltd

Jution silicone are a professional silicone teethers manufacturer in China. With rich experience in silicone teethers manufacturing, provide one-stop silicone technical support from material to mass production. Jution is the top choice of high-end silicone teethers for baby brands, wholesalers, retailers.

The in-house capabilities include: Product design and development Engineering silicone mold making, silicone molding: Compression molding, Liquid silicone rubber (LSR)molding, Co-injection dripping molding. Multicolored silicone products printing and painting assembling, package, quality assurance.

Jution Silicone & Rubber (Dongguan) Co., Ltd located at “world factory” base – Dongguan City, over 5000 square meters dust-free workshop and 200 skilled employees.

|

English name |

Jution Silicone & Rubber (Dongguan) Co., Ltd |

|

Chinese name |

东莞市众盛硅胶制品有限公司 |

|

Official Site |

https://jutionsilicone.com/(EN), https://jutionsilicone.com/ja/(JA) |

|

Company Address |

Zhengkeng Industrial Area, Dongkeng Town, Dongguan, Guangdong, China |

|

Occupied Area |

5000 square meters |

|

Annual Production Capacity |

20-55K /day, approximately 30,000 tons |

|

Annual Output Value |

68 million in US dollars |

|

Company Advantages |

Z.S.R International Group (HONG KONG) CO., Limited

Z.S.R International Group (HONG KONG) CO., Limited is an customized silicone products enterprise integrating the design, development, production, package, printing. The founder has been deeply involved in the silicone products industry for 26 years and founded first silicone molding factory in 2007 in Donguan.

In the past 18 years, Z.S.R International Group (HONG KONG) CO., Limited has continued to improving. In order to provide customers with competitive silicone products, it has established five independent production factories: silicone compression molding factory, liquid silicone molding factory, dripping molding production factory, silicone leather cure fabric molding factory and mold manufacturing factory. The total production workshop area exceeds 30,000 square meters and currently has more than 300 employees. The factory has 6 fully automatic EMD spark machines, 10 advanced CNC machining centers, 48 compression molding machines, 16 dripping molding production lines, 12 liquid silicone injection molding machines, and printing, spraying, dust-free workshops (100,000 level) and other complete production and supply systems.

The silicone products what Z.S.R custom widely covering silicone daily necessities, baby products, gifts, electronic and device protective case, in consumer filed, also medical, commercial, industrial filed.

|

English name |

Z.S.R International Group (HONG KONG) CO., Limited |

|

Chinese name |

香港众盛国际集团有限公司 |

|

Official Site | |

|

Company Address |

Zhengkeng Industrial Area, Dongkeng Town, Dongguan, Guangdong, China |

|

Occupied Area |

30,000 square meters |

|

Annual Production Capacity |

20-550K /day, approximately 60,000 tons |

|

Company Advantages |

1. Direct from the Manufacturer: Z.S.R is the original manufacturer for silicone teethers. Customers can purchase the silicone products directly from the source, eliminating the need for middlemen and ensuring the best possible prices. 2. One-stop customized OEM/ODM solutions and diversified customization and branding capabilities Since its establishment in 2007, Z.S.R has provided full-process services from design, proofing, mold manufacturing, molding, printing, assembly to quality inspection and packaging. Customers can complete the entire production chain from the same supplier. Supports a variety of logo processes: in-mold engraving, laser, silk screen, thermal transfer and epoxy; can customize color (Pantone), texture, packaging methods according to customer needs to achieve highly branded output. 3. Rich production capacity and advanced technical equipment Owns: 32 compression molding machines, 12 liquid silicone molding machines (LSR), 8 multi-color co-injection molding equipment; CNC numerical control and EDM spark machines are used for mold manufacturing and debugging; and the daily production capacity reaches 20-550k pieces to ensure efficient delivery of large-volume orders 4. Strict quality management and international qualification certification comprehensive quality assurance and after-sales service The quality and social responsibility systems that have been obtained include: ISO9001, ISO14001, SA8000, BSCI, SEDEX, BRC, FCCA, NBCU, Disney and other certifications; The materials used comply with international food and safety standards such as FDA, LFGB, EN71, CE, ROHS, REACH, etc. 5. Strong R&D team and mold manufacturing capabilities Equipped with 12 technical design engineers, who are good at product development, structural design and mold optimization; At the same time, they have mold surface treatment capabilities, such as polishing, laser engraving, coating, sandblasting, etc., to support highly customized needs 6. Stable and fast delivery and perfect after-sales system With global logistics shipping channels (DHL/UPS/FedEx Sea and air transportation), and provide complete after-sales service; through strict production monitoring and quality inspection system, ensure that orders are delivered to customers on time and with quality standards 7. Free Samples: Z.S.R provides free samples for quality reference with the clients pay the shipping cost. so, customers can see and assess the products firsthand—seeing is believing. |

All Silcone Products

Joey Silicone Tech Co., Ltd

Joey Silicone has provided customers with high-quality services for 3 years. The company mainly provides: new silicone material technology research and development; silicone rubber product manufacturing; rubber product sales; kitchenware, sanitary ware and daily sundries research and development; hardware product manufacturing; hardware product wholesale; mold manufacturing; mold sales; arts and crafts and ceremonial products manufacturing; arts and crafts and ceremonial products sales; high-quality synthetic rubber sales; synthetic material manufacturing; synthetic material sales; electronic product sales; import and export of goods.

|

English name |

Joey Silicone Tech Co., Ltd |

|

Chinese name |

东莞玖壹硅胶科技有限公司 |

|

Official Site | |

|

Company Address |

Dongkeng Town, Dongguan City, Guangdong Province, China |

|

Occupied Area |

3000 square meters |

|

Annual Production Capacity |

18-45K /day, approximately 20,000 tons |

|

Annual Output Value |

38 million in US dollars |

Mingchuan Dijiao Gift Co., Ltd

Mingchuan Dijiao Gift Co., Ltd is a leading manufacturer of multi-colored baby products (baby teethers, feeding bottles, baby bibs, baby toys and pacifiers) and kitchenware (cookware, tableware, silicone molds and baking utensils) with over 2000 products, mainly distributed in Europe Japan, Korea, Australia USA/Canada and Brazil. Our factory is in China and sales department is in the United States.

Our factory in Dongguan covers an area of 2500square meters and has 83 employees. With over 23 years of experience in this field, we have developed our own R&D team to create over 300 new products and OEM every year.

|

English name |

Mingchuan Dijiao Gift Co.,Ltd |

|

Chinese name |

东莞市铭川滴胶礼品有限公司 |

|

Official Site | |

|

Company Address |

Dongkeng Town, Dongguan City, Guangdong Province, China |

|

Occupied Area |

2500 square meters |

|

Annual Production Capacity |

30-65K /day, approximately 20,000 tons |

|

Annual Output Value |

49 million in US dollars |

Dongguan Wisdom-win Gift Co., Ltd

Dongguan Wisdom-win Gift Co., Ltd. is a factory specializing in multi-colored silicone products and customized silicone gifts. It is committed to providing customers with professional multi colored silicone gift design, customization and production services.

Dongguan Wisdom-win Gift Co., Ltd was founded in 2013. Over the past 12 years, the company has continued to change to better provide customers with competitive silicone products. It has 15 drip molding production lines, mainly producing multi-color drip products, and is equipped with printing, spraying, and other complete production and supply systems. They are specializing in the development, design, production and processing of silicone epoxy accessories, silicone epoxy mobile phone cases, USB flash drive cases, key epoxy tags, epoxy placemats, silicone epoxy bracelets, epoxy necklaces, silicone epoxy trademarks, epoxy environmentally friendly trademarks, epoxy pendants, epoxy dolls and other gifts.

The silicone raw materials, spray paint and printing materials we use all meet export standards. The products have passed environmental safety tests and meet various testing requirements such as ROHS/FDA/LFGB/UL. With its strong strength and excellent customer service, the company conducts full inspections on all products to ensure strong quality. We can develop and produce various types of silicone rubber products according to customer drawings, samples, and self-design. Our products have been distributed in more than 30 countries and regions around the world, with internationally renowned customers such as SONY, COCA-COLA, HELLO KITTY, AVON, etc. silicone products as the core, covering silicone daily necessities, baby products, gifts, medical, electronics, industry and other silicone product fields.

|

English name |

Dongguan Wisdom-win Gift Co., Ltd |

|

Chinese name |

东莞市智盛礼品有限公司 |

|

Company Address |

Dongkeng Town, Dongguan City, Guangdong Province, China |

|

Occupied Area |

3000 square meters |

|

Annual Production Capacity |

25-65K /day, approximately 30,000 tons |

|

Annual Output Value |

49 million in US dollars |

Dongguan Belledo Silicone Technology Co., Ltd.

Dongguan Belledo Technology Co., Ltd. has more than ten years of industry experience and is a modern enterprise specializing in liquid silicone solid silicone (LSR) products, plastic products, process research and development, new product customization (OEM/ODM) production and processing, and silicone mold design and production. Our company can provide you with precision liquid silicone mold opening, liquid silicone rubber (LSR) injection molding, multi-material (plastic, hardware, etc.) liquid silicone encapsulation injection molding, product assembly and packaging and other services.

|

English name |

Dongguan Belledo Silicone Technology Co., Ltd. |

|

Chinese name |

东莞贝乐多硅胶科技有限公司 |

|

Company Address |

Dongcheng, Dongguan City, Guangdong Province |

|

Occupied Area |

1000 square meters |

|

Annual Production Capacity |

19-29K /day, approximately 20,000 tons |

Dongguan Weishun Silicone Technology Co., Ltd

Dongguan Weishun Silicone Technology Co., Ltd. was established in 2009 and is located in Hengli Town, Dongguan City, Guangdong Province. It is a silicone product manufacturer with more than ten years of manufacturing experience. From a small factory with less than 10 people at the beginning, it has developed into a factory with more than 100 people, a factory area of more than 3,100 square meters, more than 50 related machines and equipment, and an annual output value of more than 20 million. The factory has accumulated rich production and manufacturing technology experience from R&D design, mold opening, processing and molding, quality inspection and packaging. Our company mainly deals in: maternal and child, daily dining and kitchen utensils, daily household goods, toys, lighting, pet products, medical equipment accessories and other related silicone products. We can open molds and customize products according to user requirements, drawings, samples and other requirements.

|

English name |

Dongguan Weishun Silicone Technology Co., Ltd. |

|

Chinese name |

东莞伟顺硅胶科技有限公司 |

|

Company Address |

Hengli Town, Dongguan City, Guangdong Province |

|

Occupied Area |

3100 square meters |

|

Annual Production Capacity |

30-50K /day, approximately 50,000 tons |

Dongguan Youhang Rubber & Plastic Products Co., Ltd

Dongguan Youhang Rubber & Plastic Products Co., Ltd., founded in 2015, is a silicone rubber product manufacturer integrating R&D, design, production and sales. It currently has more than 100 employees and covers an area of more than 8,300 square meters. The company mainly produces silicone ice trays, silicone maternal and child products, ice cream molds, resin molds and other silicone daily necessities, with many categories and styles. It can design and develop molds and products according to customer requirements, and support OEM and ODM orders.

|

English name |

Dongguan Youhang Rubber & Plastic Products Co., Ltd. |

|

Chinese name |

东莞市友航橡塑制品有限公司 |

|

Company Address |

Liaobu Town, Dongguan City, Guangdong Province. |

|

Occupied Area |

1800 square meters |

|

Annual Production Capacity |

25-35K /day, approximately 9,500 tons |

Dongguan Zhixing Baby Products Co., Ltd.

Dongguan Zhixing Baby Products Co., Ltd. has been focusing on the silicone field for 21 years. It is located in Shipai Town, Dongguan City. It is a large-scale silicone factory integrating independent research and development design, mold opening, production, sales and service. The main products are: maternal and infant feeding tableware, teether chewing music, children’s toys, stationery gifts, silicone daily necessities, etc.

Factory area: 19,260 square meters of factory building / 7,280 square meters of warehouse. Main equipment: Large hydraulic workshop: 62 solid-state machines, 16 liquid machines, 36 injection molding machines, 22 dispensing machines, 11 CNC machines, 12 spark machines, 6 mold beds, 69 printing machines, and 6 thermal transfer machines.

|

English name |

Dongguan Zhixing Baby Products Co., Ltd |

|

Chinese name |

东莞市致兴婴童用品有限公司 |

|

Company Address |

Liheng Avenue, Shipai Town, Dongguan City, Guangdong Province. |

|

Occupied Area |

800 square meters |

|

Annual Production Capacity |

15-25K /day, approximately 9,000 tons |

Dongguan Baiya Silicone Products Co., Ltd

Dongguan Baiya Silicone Products Co., Ltd. adheres to the business philosophy of “integrity-based, quality-oriented, continuous innovation, common prosperity and win-win”, continues to innovate, and focuses on the research and development, design, manufacturing and sales of various baby products. After years of unremitting efforts, it has become a company specializing in the production and wholesale of pacifiers, baby bottles, children’s drinking cups, kettles, silicone bottles, breast pumps, bottle brushes, silicone spoons, pacifiers, milk powder boxes, bottle straws, bottle accessories, baby tableware and other series of feeding supplies.

|

English name |

Dongguan Baiya Silicone Products Co., Ltd. |

|

Chinese name |

东莞市百亚硅胶制品有限公司 |

|

Company Address |

Dongguan City, Guangdong Province |

|

Occupied Area |

1000 square meters |

|

Annual Production Capacity |

29-49K /day, approximately 39,000 tons |

Related Blog

-

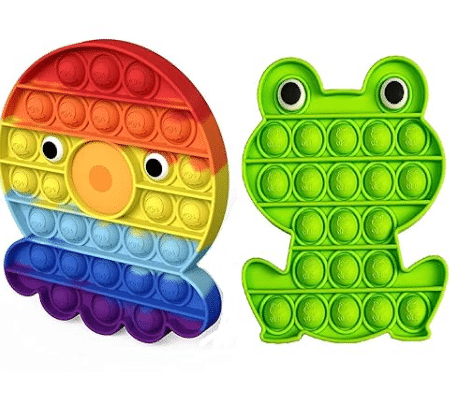

The diversity of silicone toys Stimulating babies’ desire for exploration

The diversity of silicone toys Stimulating babies’ desire for exploration As a professional with many years of experience in the field of silicone materials, I have witnessed how silicone materials have reshaped the landscape of maternal and infant products with their unparalleled safety and functionality. During the critical period of a baby’s growth, appropriate sensory

-

The baby’s first water cup Recommended

The baby’s first water cup Recommended Over the years, I have witnessed how silicone materials have reshaped the landscape of maternal and infant products with their unparalleled safety and functionality. The “first water cup” is an important tool for babies to transition from breast milk or bottles to independent drinking. At this time, our top

-

Silicone vs. Plastic Why are silicone baby products more recommended

Silicone vs. Plastic Why are silicone baby products more recommended As a professional with many years of experience in the silicone material field, I’ve witnessed how silicone, with its unparalleled safety and functionality, has reshaped the landscape of maternal and infant products. In this age of information overload, the sheer variety of baby products available

-

Silicone baby training spoon – Soft head to prevent choking and allows independent feeding of solid food

Silicone baby training spoon – Soft head to prevent choking and allows independent feeding of solid food As a professional who has been deeply engaged in the field of silicone materials for many years, I have witnessed how silicone materials have reshaped the landscape of maternal and infant products with its unparalleled safety and functionality.

-

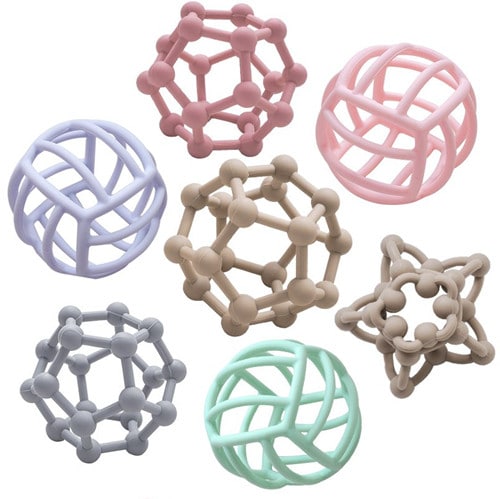

Silicone baby sensory ball, textured surface grasping training toy

Silicone baby sensory ball, textured surface grasping training toy As a professional who has been deeply engaged in the field of silicone materials for many years, I have witnessed how silicone materials have reshaped the landscape of maternal and infant products with its unparalleled safety and functionality. The early sensory development of infants and young

-

New mom must-see! Silicone toys, helping you say goodbye to the chaotic parenting life

New mom must-see! Silicone toys, helping you say goodbye to the chaotic parenting life As a professional with many years of experience in the silicone materials field, I’ve witnessed firsthand how this remarkable material has evolved from industrial applications to critical areas that contribute to human development. Daily tasks like caring for, feeding, comforting, and

-

Early education and intelligence-enhancing silicone teether rattle

Early education and intelligence-enhancing silicone teether rattle I am a senior practitioner who has been deeply involved in the silicone industry for many years. Over the years, I have witnessed how silicone materials have developed from a single industrial use to a magical medium that empowers the early develo pment of infants and young children.

-

Cute and fun silicone baby toothbrush, protecting your baby’s oral health

Cute and fun silicone baby toothbrush, protecting your baby’s oral health As a senior practitioner who has been deeply involved in the silicone industry for many years, in my career, I have witnessed how silicone has revolutionized countless maternal and infant products with its excellent safety and unique functionality. Today, I would like to discuss