Silicone vs. Plastic Why are silicone baby products more recommended

As a professional with many years of experience in the silicone material field, I’ve witnessed how silicone, with its unparalleled safety and functionality, has reshaped the landscape of maternal and infant products. In this age of information overload, the sheer variety of baby products available is dizzying, but your baby’s health and safety are always paramount. Today, based on extensive scientific data, user feedback, and professional experience, I’ll provide an in-depth analysis of the essential differences between silicone and plastic, their specific advantages, applicable areas, and target demographics, as well as purchase considerations and cleaning and maintenance methods.

If you’re interested in silicone baby products or want to learn more, please read this article.

What are silicone and plastic?

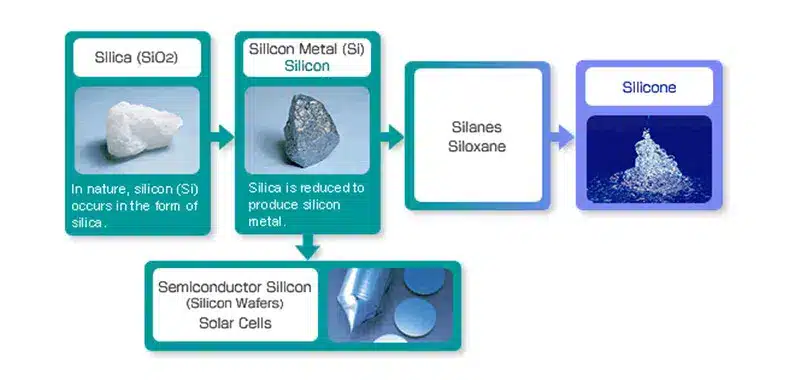

Silicone is a polymer material composed of silicon, oxygen, carbon, hydrogen and other elements with a stable chemical structure. Silicone material has excellent properties such as high and low temperature resistance, oxidation resistance, and electrical insulation, and has gradually been widely used in many industries such as medical, food, and electronics.

Plastic refers to a class of polymer compounds that can be shaped and retain their shape at room temperature. Plastics have rapidly become an important alternative to traditional wood and metal materials due to their light weight, ease of processing, and low cost.

Why are silicone products more suitable for infants and young children?

Temperature adaptability:

Silicone can remain stable in a very wide temperature range and is resistant to both high and low temperatures; most plastics are more sensitive to temperature, tend to soften at high temperatures, and may become brittle at low temperatures.

Elasticity and hardness:

Silicone generally has good elasticity and flexibility, and can quickly return to its original shape even after long-term compression; while plastic has a wide range of hardness.

Aging Resistance:

Silicone’s chemical structure is stable, making it highly resistant to environmental factors and less susceptible to aging over time. Some plastics, on the other hand, will fade after prolonged exposure to outdoor conditions.

Environmental Protection:

Silicone is recyclable and does not produce toxic gases when burned, making it relatively environmentally friendly. Plastic, on the other hand, is difficult to degrade, and large amounts of discarded plastic pollute the natural environment.

Price cost:

Compared with plastic, the unit price of silicone is higher, but plastic has low durability and needs to be replaced frequently, which has high hidden costs.

If you want to know more about silicone products, please contact us JUTION.

Who is suitable to use silicone products and plastic products?

Consider silicone products

Highly recommended for safety-conscious parents: Silicone is chemically inert and releases no harmful substances. It has passed the strictest FDA and LFGB certifications. Silicone products are resistant to high and low temperatures, age-resistant, and non-irritating to the skin, making them safe for purchase and customization.

Infants and young children: Silicone products are soft and skin-friendly, non-toxic and odorless, so babies can chew and play with them without worry.

Health-conscious individuals: Silicone products release no harmful substances, making them ideal for those who value their health.

Environmentally friendly individuals: Silicone materials are recyclable and environmentally friendly. Silicone products are a good choice for those who value environmental protection and advocate sustainable development.

At JUTION, you can also customize silicone products of different colors and shapes, and I believe your children will love them.

Consider plastic products

For families on a limited budget: Plastic products, which tend to be less safe, are more affordable and suitable for those with limited funds.

For short-term temporary use: The safety of plastic products cannot be guaranteed, but temporary use is acceptable.

When is it appropriate to use silicone products and plastic products?

Silicone product applicable time

Oral stage:

Babies aged 0-6 months primarily perceive objects through chewing. They frequently suck on their fingers and surrounding objects. Parents are advised to prepare sterilized silicone teethers or sensory toys to satisfy their baby’s sensory needs while promoting gum development.

Self-feeding period:

Silicone tableware is durable and shatterproof, so you don’t have to worry about your baby spilling their own food. Silicone bowls and spoons are not easily stained by oil, eliminating unnecessary cleaning troubles.

Baby teething period:

When the baby teeth erupt, the gums are swollen and painful. Silicone tableware can be used as feeding tools and chewing gums, which can not only exercise the baby’s ability to eat independently, but also relieve the baby’s gum discomfort.

Outdoor travel:

Silicone products are light, easy to carry, and not easy to break, making them very suitable for outdoor activities or travel.

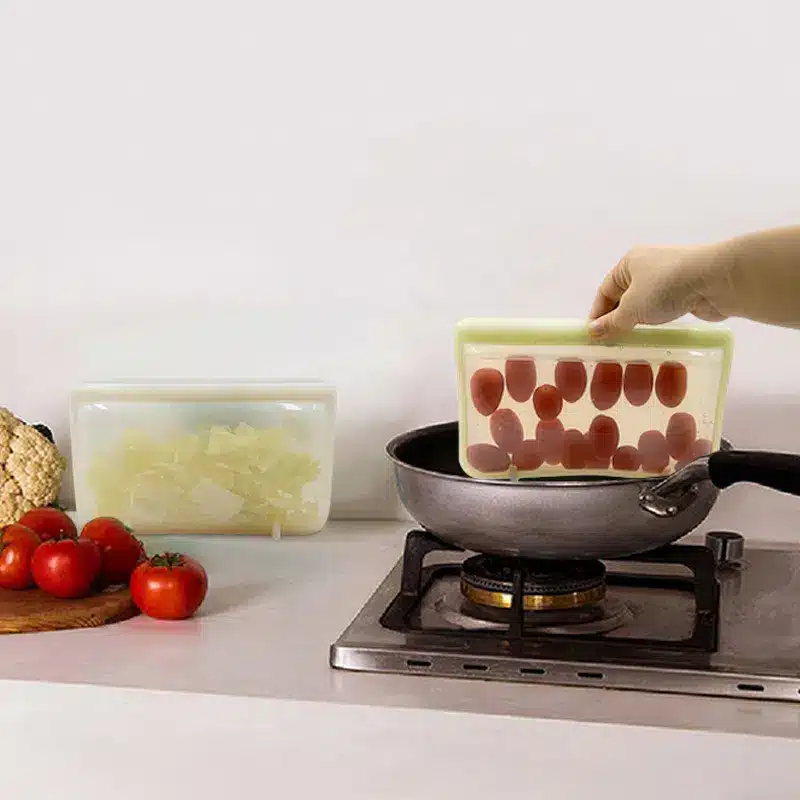

Baking and refrigeration:

Silicone products are resistant to high and low temperatures and will not release harmful substances. They can be safely placed in ovens, microwaves, or refrigerators.

Plastic product applicable time

Food preservation:

Plastic wrap, boxes, and bottles can be used to store food and water, but they should not be used to hold hot water or for long-term recycling.

Daily storage:

Silicone storage boxes and basins can be used to store stationery, cosmetics and sundries, but they cannot be exposed to direct sunlight or high temperature for a long time.

Which fields are suitable for using silicone and plastic as raw materials?

Suitable for applications using silicone as a raw material

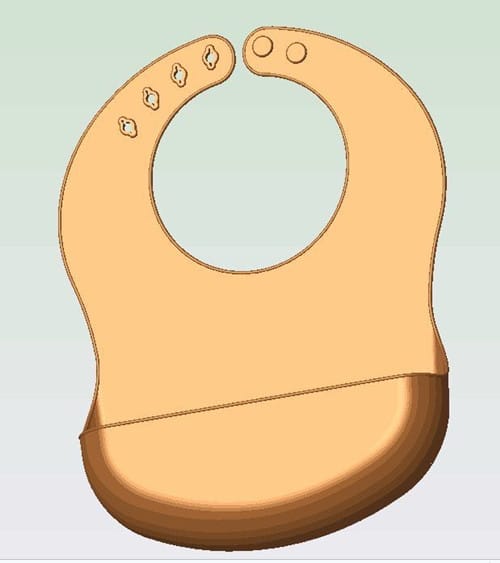

Maternal and infant products:

Food-grade silicone is non-toxic, environmentally friendly, soft and comfortable. Common maternal and infant products such as pacifiers, bottles, and teethers are made from it. Furthermore, silicone’s easy processing and molding properties allow it to be designed into a variety of cute shapes and colors, attracting babies’ attention and satisfying their needs.

Kitchen supplies:

Silicone’s high temperature resistance allows it to be used in high temperature environments, such as baking molds that can withstand high temperature baking without releasing harmful substances, improving the convenience and safety of kitchen supplies.

Medical field:

Silicone has the characteristics of biocompatibility and high temperature resistance, and is often used to manufacture medical devices and surgical instruments.

Electronics:

Silicone has good electrical insulation and high temperature resistance. It is used as a packaging and insulation material in electronic components to protect circuit boards and sensitive electronic components.

Suitable for applications using plastics as raw materials

Packaging materials:

Plastic bags, bottles, and cans are used for packaging food and medicine. Common materials include polyethylene (PE) and polypropylene (PP).

Automotive Industry:

Plastics are widely used in interior trims, tires, seals, and other applications, reducing vehicle weight and improving safety. Common materials include PP and ABS.

Building Materials:

Plastic pipes (such as PVC pipes) and sheet materials (such as acrylic sheets) are used in building water supply and drainage, wire and cable conduits, and interior decoration.

If you want to customize silicone products, please contact us JUTION.

How to produce silicone products and plastic products?

Silicone Product Production

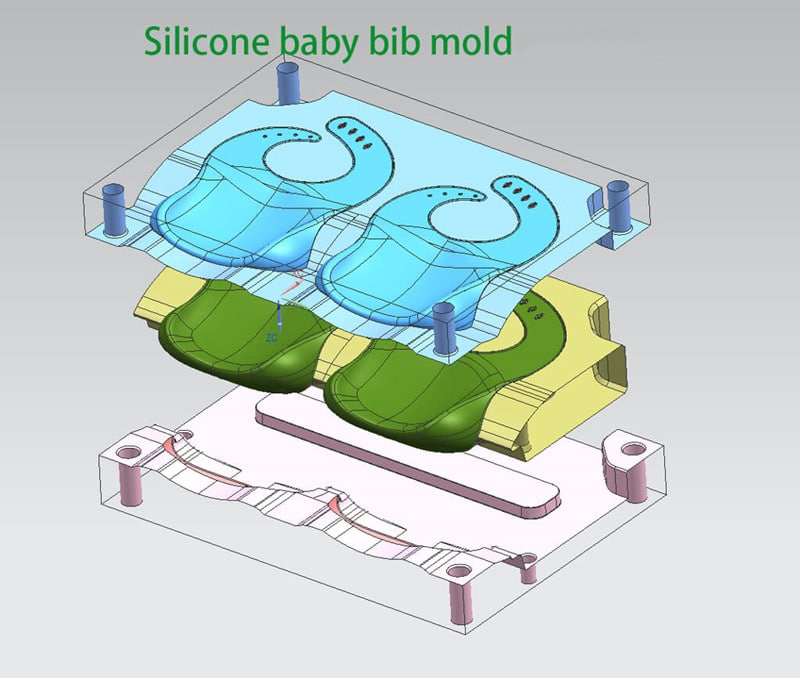

Compression Molding: Solid silicone raw materials are cut into pieces and placed into molds. The molds are then formed using a vulcanizer at high temperatures (150-180°C) and pressure (10-20 MPa). This method is suitable for mass production of simple products such as seals and gaskets.

Injection molding: Liquid silicone is injected into the mold in proportion through an injection molding machine and hardens quickly at 120-160°C. It is suitable for complex and fine-structured products (such as baby pacifiers and medical catheters). The output of a single mold is 30% higher than that of the compression molding process.

Extrusion molding: Suitable for tubular and strip products (such as silicone tubes and sealing strips). The mixed raw materials are extruded through the extruder screw and then heated by hot air or microwave to shape.

Coating molding: Cover the surface of the material with a silicone layer by dipping, spraying or scraping, with a thickness of 0.1-2 mm, used for anti-slip handles, insulation layers, etc.

Plastic Product Production

Injection Molding: Raw materials (such as plastic pellets) are heated and melted before being injected into a mold. Under high pressure, complex structural products (such as appliance housings and automotive parts) are formed. This process is characterized by high efficiency and automation.

Insert Molding: Metal or non-metal inserts are pre-fixed in the mold and then bonded to the molten plastic. This process is suitable for integrated, complex products (such as electrical accessories).

JUTION. is a one-stop custom silicone product manufacturer and silicone molding solutions provider specializing in silicone products. If you would like custom silicone products, please contact us.

How to choose high-quality baby silicone products?

Safety:

High-quality silicone material should be non-toxic and odorless and meet relevant national safety standards. When purchasing, parents should carefully check the product’s safety certification to ensure that the selected product will not pose a threat to the baby’s health.

Pay attention to the recommended age range:

Different silicone products are suitable for different ages, so choose a silicone product that’s appropriate for your baby’s age range.

Pay attention to product details:

Silicone baby products should have a complete design. Check that the edges are smooth and that small parts are secure to avoid the risk of accidental swallowing.

Practicality:

The efficacy of silicone products and the color and shape of the selected products are related to the interest of the baby when playing and using them. You can choose silicone products that the baby likes and take advantage of their development in certain areas.

How to control the quality of silicone products and plastic products?

Raw Material Quality Control

Supplier Audit: Select suppliers with established quality management systems, environmental compliance, and a history of stable supply, and regularly evaluate their qualifications.

Raw Material Testing: Silicone raw materials require testing for appearance (color, impurities), physical properties (hardness, tensile strength), and chemical properties (acid and alkali resistance, aging resistance). Plastic raw materials require testing for melt index, impact strength, and other indicators.

Storage Management: Silicone raw materials must be stored dry and away from light. Plastic raw materials must be protected from moisture and static electricity. A first-in, first-out principle must be followed for both.

Production Process Optimization

Formula Design: Silicone formulations must balance raw material compatibility and processing temperature. Plastic formulations must prioritize the matching of material flowability and mechanical properties.

Molding Process

Silicone injection molding requires precise control of pressure and temperature (e.g., LSR injection rate: 15-25 g/s). Plastic injection molding requires regulation of melt temperature and mold temperature.

Post-treatment: Silicone needs to be vulcanized to enhance cross-linking, and plastic needs to be annealed to reduce internal stress.

Finished Product Inspection and Feedback

Dimensional Accuracy: Silicone products are inspected for dimensional tolerances, while plastic products are measured for shrinkage and warpage.

Appearance Inspection: Silicone products are inspected for bubbles and cracks, while plastic products are inspected for weld marks and surface gloss.

Performance Testing: Silicone is tested for heat resistance and aging performance, while plastics are tested for impact toughness and fatigue strength.

Environmental Adaptability: Silicone must pass weathering tests, while plastics undergo low-temperature impact testing.

At JUTION, we provide comprehensive support from conception to market, making us the preferred partner for leading silicone product brands and retailers.

How to clean and maintain silicone products?

Silicone Product Cleaning

Warm Water Cleaning Method: Use warm water at 40-50°C (40-50°C) with a neutral detergent (such as dishwashing liquid) and a soft cloth or sponge. Avoid using bleach or strong acid/alkaline cleaners.

White vinegar + baking soda: Mix white vinegar and water in a 1:1 ratio and use baking soda to remove stains. This is suitable for stubborn stains.

Disinfection: Wipe the surface with a non-toxic disinfectant spray or 70%-75% rubbing alcohol and ensure it is completely dry.

Plastic Product Cleaning

General Cleaning: Plastic toys can be cleaned with soapy water or a mild detergent. Avoid soaking or drying in high temperatures.

Disinfection Recommendations: Use a UV sterilizer or low-temperature dryer to avoid direct exposure to high temperatures.

Conclusion

Silicone products are superior in terms of safety, durability, and environmental friendliness, making them particularly suitable for babies who have extremely high health requirements. Although low-priced plastic products still dominate the market, choosing silicone products is more economical and safer. It is not only a sustainable and green choice, but also a guarantee of safety for your baby! When purchasing silicone products, it is important to pay attention to quality certification and understand the proper use and maintenance methods to maximize the value of the product.