Temperature and Silicone

What is the temperature range of silicone?

The temperature range of silicone varies according to the type and use.

The temperature resistance range of ordinary silicone is usually between -55°C and 250°C, but the highest tolerable temperature can reach about 350 ° C in a short time;

The temperature resistance of high temperature silicone is more excellent, its temperature range can reach -100℃ to 400℃, and even some special formulas such as new flame retardant silicone can withstand 1500℃ high temperature ;

Food-grade silicone generally has a temperature resistance of about 250℃-300℃. When used in this temperature range, its status and volume will not change significantly, nor will there be bleaching .

Why does silicone have such temperature characteristics?

Chemical structure:

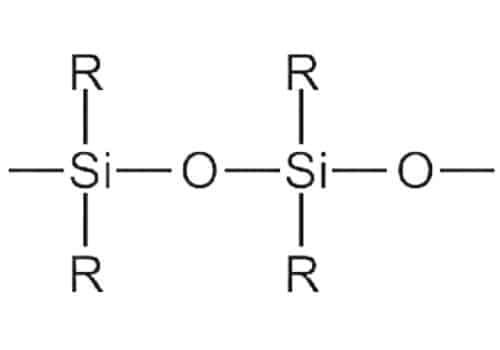

Silicone is a high-purity inorganic silicon compound whose molecular structure is formed by the covalent bond between silicon atoms and oxygen atoms to form a continuous three-dimensional network structure.

This structure not only gives the silicone extremely high thermal stability, but also makes it able to maintain its original properties and forms under high temperature environment.

Physical properties: Silicone has good flexibility and elasticity, and can maintain the integrity of its own structure even when subjected to external forces. In addition, silicone also has excellent electrical insulation, which is not affected by humidity and temperature.

Where silicone is affected by temperature?

- Aerospace field: Silicone is used in aerospace equipment to make high temperature and heat resistant coatings. Some silicone materials such as foamed silicone can work at a temperature of -100℃ to 350℃, and can even withstand thousands of degrees of instantaneous high temperature .

- Automotive industry: silicone can maintain its physical and chemical stability under high temperature environment. Silicone is used in the automotive industry to make a variety of seals, shock absorbers and insulation materials, which need to withstand high temperature, high pressure and oil erosion .

- Electronic and electrical industry: In the packaging and protection of electronic components, silicone can remain stable in high temperature environments. For example, silicone seals and cooling materials in electronic equipment can be used for a long time within the normal operating temperature range of the equipment, ensuring the stability and durability of the equipment .

When is silicone affected by temperature?

The processing and use of silicone will indeed be affected by temperature, which is reflected in the following aspects:

How does temperature change affect silicone?

Reduced sealing performance: silicone products such as sealing rings, gaskets, etc. may be deformed or hardened at high or low temperatures, resulting in reduced sealing performance. This may affect the normal operation of the device and even cause security risks.

Weakening of mechanical properties: temperature also has a significant effect on the mechanical properties of silicone. At high temperature, the tensile strength and tear strength of silicone may be reduced; At low temperatures, the hardness of silicone increases, which may lead to a decline in its impact resistance.

Who cares about the effect of temperature change on silicone?

- Users: Users in different application scenarios need to pay attention to the temperature resistance of silicone materials in this temperature range to ensure product safety and reliability. Users of silicone products need to adjust the use and maintenance methods according to temperature changes to ensure the performance and life of silicone products under various temperature conditions.

- Manufacturers: Silicone manufacturers need to pay attention to the impact of temperature changes on the ratio of silicone raw materials and curing agents to ensure the curing effect and performance of silicone at different temperatures, and in order to improve the quality and stability of silicone products, manufacturers need to study the impact of temperature changes on the parameters of the silicone production process.

- Related industry professionals: they may be engaged in the research and development, testing or application of silicone materials, these people need to have an in-depth understanding of the effect of temperature changes on the properties of silicone in order to take these factors into account when designing and developing new products.

How does silicone respond to temperature changes?

Choose the right silicone products: When choosing silicone products, the appropriate silicone material should be selected according to the temperature conditions of the use environment.

Take measures to reduce the impact of temperature on performance: When using silicone products, some measures can be taken to reduce the impact of temperature on performance. For example, when used in a high temperature environment, the heat load of silicone can be reduced by increasing the heat dissipation facility or reducing the ambient temperature; In the low temperature environment, the temperature of the silicone can be increased by heating or insulation measures.

Conclusion

By exploring the relationship between temperature and silicone, you will understand the melting temperature of silicone, the effect of heat on silicone, etc. Silicone’s exceptional temperature resistance makes it a versatile and trustworthy material in a variety of sectors. Whether sustaining high temperatures without melting or being flexible in freezing circumstances, silicone continues to prove its worth in applications ranging from kitchen utensils to car seals.

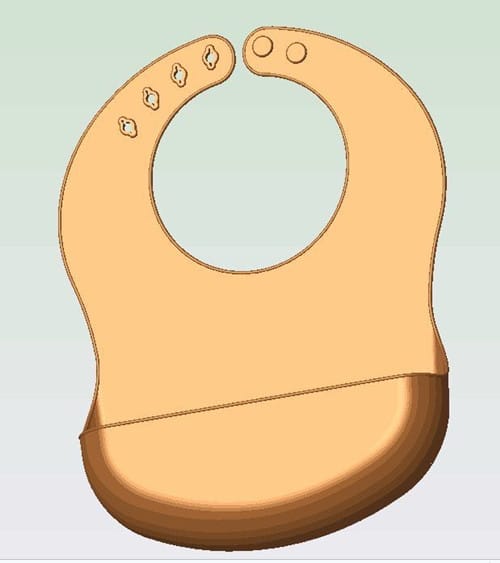

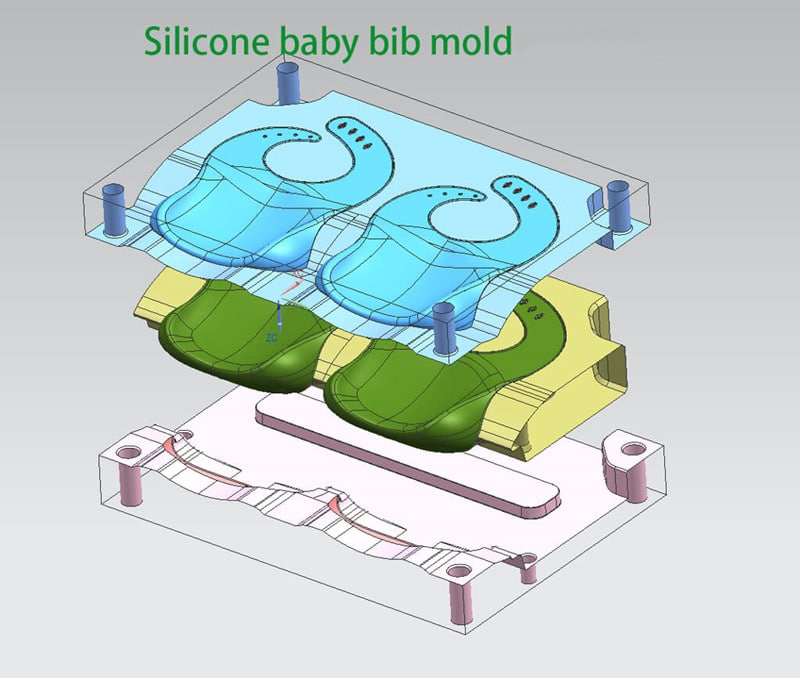

Would you like to create your silicone products brand or look for reliable and safe silicone products with your logo for your Event? Jution silicone can help. Get an online quote with free design from us for quality silicone baby products within days.

Contact Jution silicone to get your needed silicone products.