The difference between silicone and rubber

What is silicone?

silicone is a kind of highly active adsorption material, belonging to the amorphous substance, insoluble in water and any solvent, non-toxic and tasteless, chemically stable, and does not react with any substance except strong alkali and hydrofluoric acid.

Due to its chemical composition and physical structure, silicone has many characteristics that are difficult to replace with other similar materials, such as high adsorption properties, good thermal and chemical stability, and high mechanical strength.

What is rubber?

Rubber is a polymer material with high elasticity, elastic at room temperature, can produce large deformation under the action of a small external force, and can be restored to its original state after removing external force. Rubber is a completely amorphous polymer, its glass transition temperature is low, the molecular weight is often large, greater than hundreds of thousands. Rubber is divided into natural rubber and synthetic rubber, rubber products are widely used in all aspects of industry or life.

How are silicone and rubber processed?

Silicone processing method:

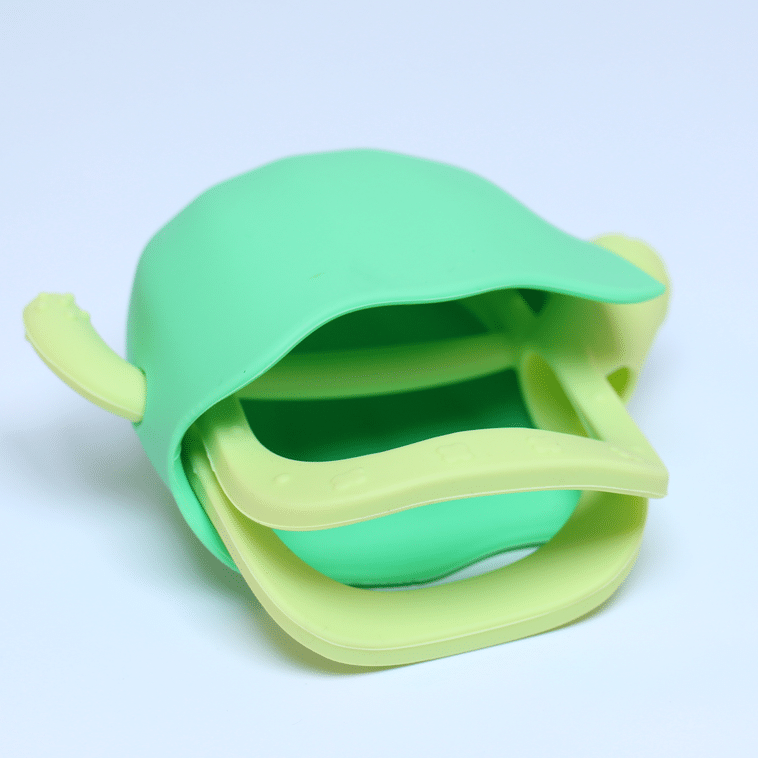

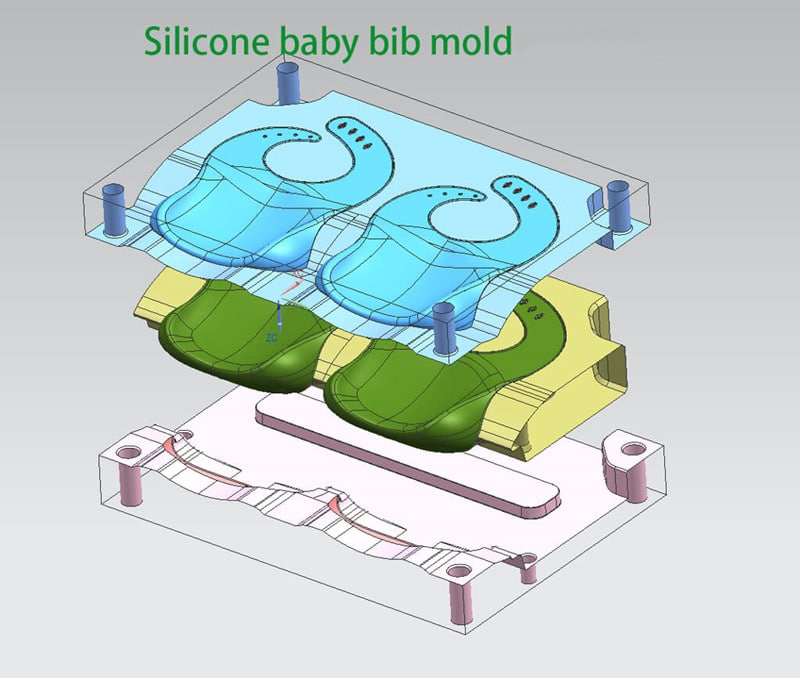

molding – the mixed silicone raw materials into the mold, through the vulcanization machine to apply pressure and high temperature to make it solid forming. Suitable for the production of complex shapes and high precision products.

Extrusion molding – The silicone raw material is extruded into long strips of a specific shape by a mold in an extruder. This method has high production efficiency and is suitable for mass production.

Injection molding – Using an injection molding machine, heated silicone material is injected into a mold, which is then cooled and cured. Suitable for products requiring high production efficiency and mass production.

Calendering – The mixture of silicone is pressed into a film of a certain thickness and width by a calendering machine for the manufacture of simple sheet and plate-like products.

Rubber processing method:

Hot press forming – The rubber material is heated in a hot press and pressed into the design shape by a mold. This method is suitable for products that require mass production. Injection molding – The use of injection molding machine to heat rubber into the mold, cooling after forming, similar to the injection molding of silicone.

Extrusion molding – Rubber material is heated in an extruder and passed through a mold to form a continuous strip shape.

Vulcanization – Rubber products usually need to be vulcanized to improve their performance and durability. Vulcanization is usually carried out under high temperature and pressure, which helps in the cross-linking reaction of rubber molecules.

Where is silicone used?

Where is rubber used?

- Tire manufacturing: Rubber is the main material in the manufacture of automotive tires, providing the necessary grip and wear resistance.

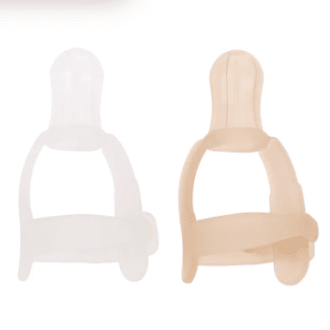

- Medical supplies: Rubber is used in the manufacture of medical supplies such as gloves, catheters, bottle stoppers, etc., taking advantage of its elasticity and sealing properties. Construction industry: Rubber is used to make seals and waterproof materials, etc., to improve the functionality and comfort of buildings.

- Military applications: Because of its high temperature resistance, low temperature resistance, oil resistance and high vacuum resistance, rubber is also widely used in the military field, such as tanks, warships and protective equipment, etc.

Who is using silicone and rubber?

Silicone is widely used in many fields because of its excellent physical and chemical properties. The following are the main users of silicone and industry applications: medical product manufacturers making medical silicone products, electronic engineers manufacturing related electronic components and relevant staff in food production.

The main body of the use of rubber with reversible deformation properties is: rubber products processing plants, tire factories and construction industry practitioners.

Why are silicone and rubber widely used?

Silicone and rubber are widely used in many fields, mainly because they have a series of excellent physical and chemical properties.

Silicone:

- Beauty and production: silicone has good molding processability and can be produced by injection molding, calendering and other processes. At the same time, the production cost of silicone rubber sleeve is not high, so that it can be used in various electronic machinery on a large scale.

- Biological stability: Silicone has good compatibility with human tissue, and will not cause strong immune reaction or toxic reaction after implantation.

- Chemical stability: Silicone has good tolerance to most acids and bases, and can maintain stable chemical properties in both acidic and alkaline environments.

Rubber:

- High elasticity: rubber can withstand a lot of deformation without breaking, suitable for cushioning and shock absorption .

- wear resistance: Rubber performs well in environments with frequent friction and is suitable for parts such as tires, conveyor belts and soles .

- Corrosion resistance: rubber can resist the erosion of many chemical substances, suitable for the manufacture of various seals and protective sleeves .

- Insulation properties: rubber has good electrical insulation properties, suitable for cable insulation layer and electronic component packaging materials .

When is it appropriate to use silicone and rubber?

Timing of use of silicone:

High and low temperature environment – Silicone has excellent heat resistance and cold resistance, suitable for applications that need to withstand high temperatures and parts of freezing equipment and low temperature laboratories.

Ultraviolet resistance and chemical stability – Silicone can resist UV damage and corrosion of a variety of chemicals, suitable for outdoor supplies and chemical industry components.

Medical and food contact – Silicone is safe and non-toxic and suitable for making medical supplies and food contact materials.

When to use rubber:

Elasticity and wear resistance – Rubber has good elasticity and wear resistance, making it ideal for applications that require wear resistance and elasticity, such as tires, conveyor belts and soles.

Sealing and shock absorption – Rubber is commonly used as a shock absorption component in construction, automotive and industrial equipment due to its good sealing and shock absorption properties.

Conclusion

So the difference between silicone and rubber was explained above. As long as you can understand the differences, you should be able to make decisions based on your needs.

Would you like to create your silicone products brand or look for reliable and safe silicone products with your logo for your Event? Jution silicone can help. Get an online quote with free design from us for quality silicone products within days.